PH-responsive modified polyacrylamide oil displacement agent and preparation method thereof

A technology of polyacrylamide oil displacement agent and acrylamide, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of immature experimental methods, lack of application and practice, and poor stability, so as to improve crude oil recovery Yield, Enhanced Crude Oil Recovery, Ease of Separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a pH-responsive modified polyacrylamide oil displacement agent, which is prepared according to the following steps:

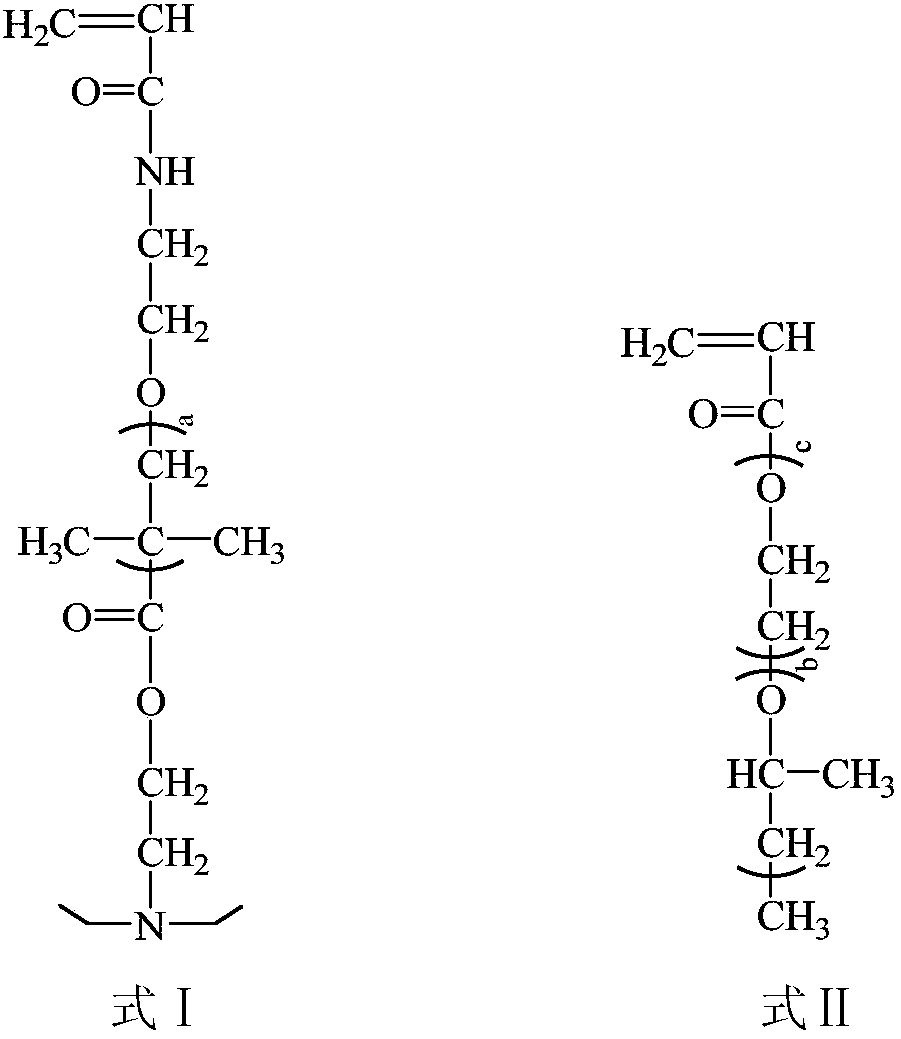

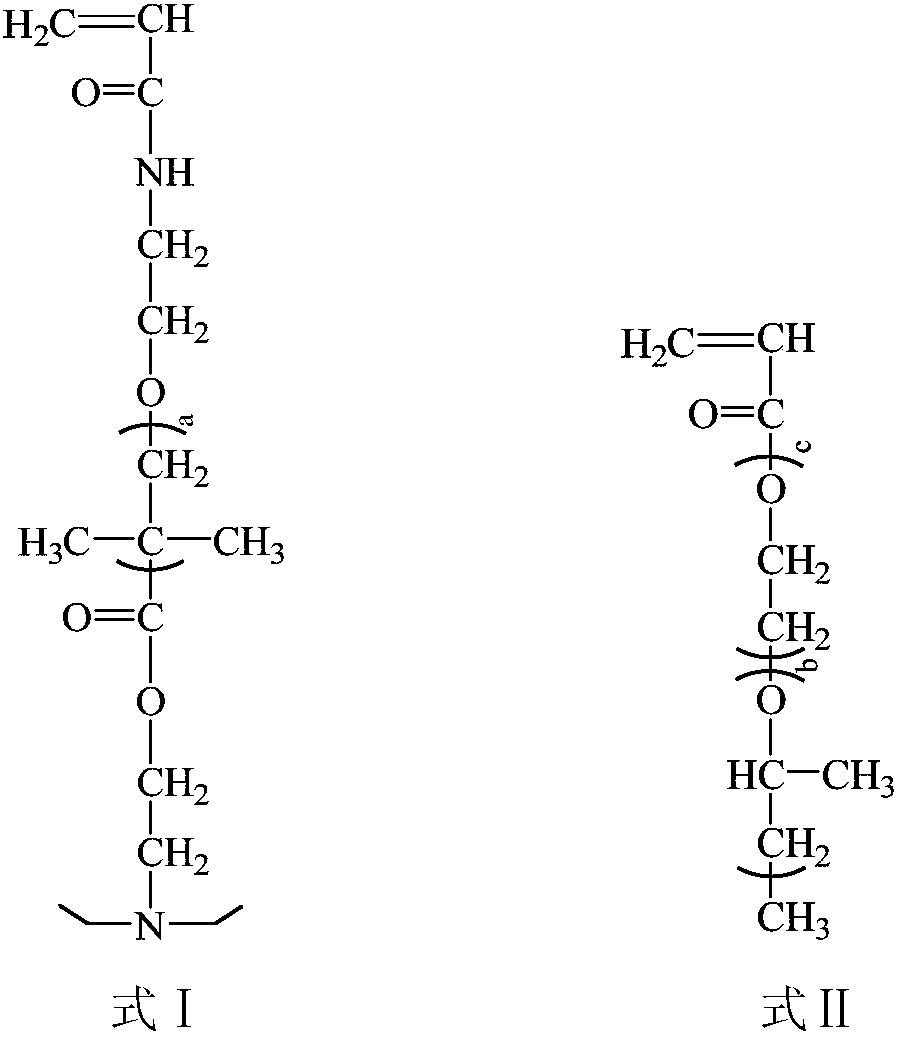

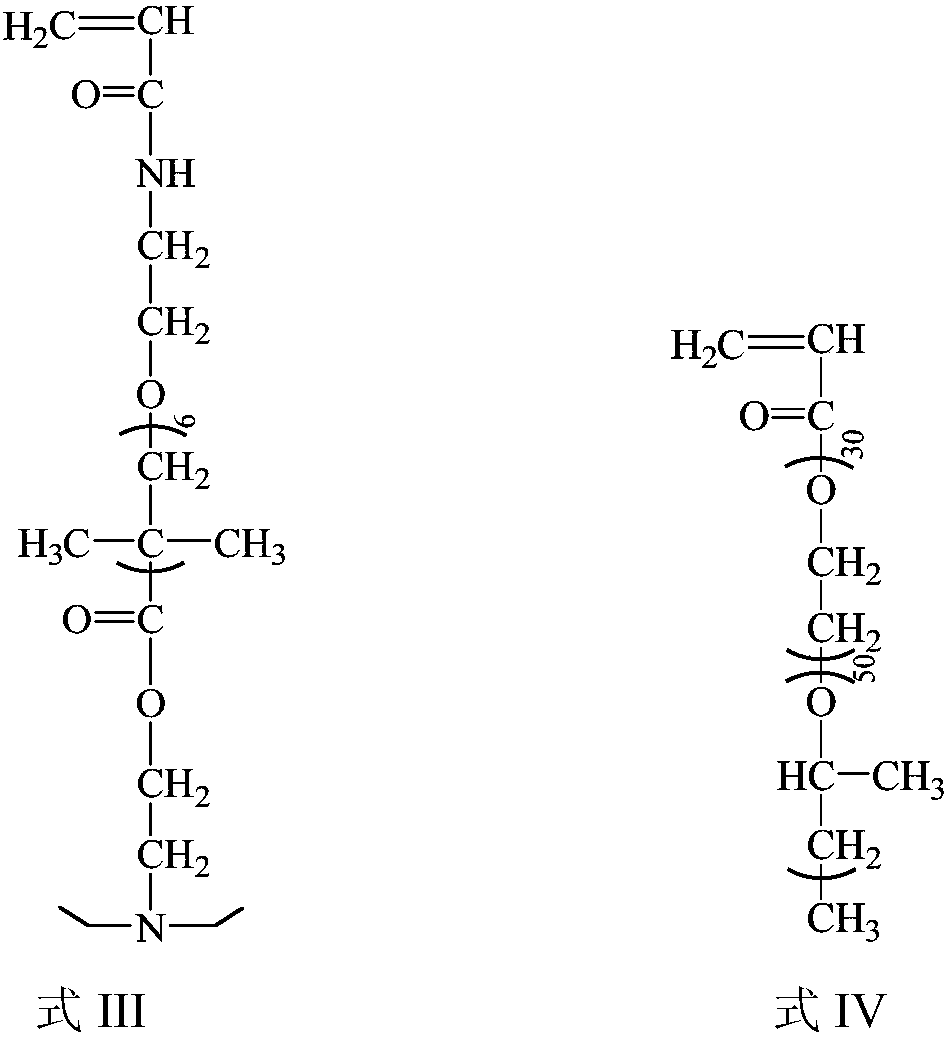

[0036] The percentages of various comonomers used in the pH-responsive modified polyacrylamide oil displacement agent in the total mass are: 68% of acrylamide, 15% of sodium acrylate; 12% of the functional monomer shown in formula III, and 12% of the functional monomer shown in formula IV 5% of functional monomers indicated.

[0037]

[0038] The specific preparation method of the functional monomer in formula III is as follows: 2mmol ethanolamine and 2mmol potassium naphthalene are added to tetrahydrofuran, and they are completely dissolved at room temperature to obtain an alcoholate initiator; 30mmol pure dry DEA monomer is quickly added to the mixed solution , after reacting at room temperature for 5 hours, the product was repeatedly precipitated and purified with cold n-hexane, and set aside; 60 mL of dichloromethane and 1...

Embodiment 2

[0042] This embodiment provides a pH-responsive modified polyacrylamide oil displacement agent, which is prepared through the following steps:

[0043] The percentages of various comonomers used in the pH-responsive modified polyacrylamide oil displacement agent in the total mass are: 65% of acrylamide, 15% of sodium acrylate, 10% of the functional monomer shown in formula V, and 10% of the functional monomer shown in formula VI. 10% of the indicated functional monomers.

[0044]

[0045] The specific preparation method of the functional monomer in formula V is as follows: 4 mmol ethanolamine and 4 mmol potassium naphthalene are added to tetrahydrofuran, and they are completely dissolved at room temperature for several minutes to obtain an alcoholate initiator; 60 mmol of pure dry DEA monomer is quickly added to the mixture In the solution, after reacting at room temperature for 5 hours, the product was repeatedly precipitated and purified with cold n-hexane for subsequent ...

Embodiment 3

[0049] This embodiment provides a pH-responsive modified polyacrylamide oil displacement agent, which is prepared through the following steps:

[0050] The percentages of various comonomers used in the pH-responsive modified polyacrylamide oil displacement agent in the total mass are: 55% of acrylamide, 15% of acrylic acid, 20% of the functional monomer shown in formula VII, and 20% of the functional monomer shown in formula VIII 10% of functional monomers.

[0051]

[0052] The specific preparation method of the functional monomer in formula VII is as follows: 2mmol ethanolamine and 2mmol potassium naphthalene are added to tetrahydrofuran, completely dissolved at room temperature to obtain an alcoholate initiator; 30mmol pure dry DEA monomer is quickly added to the mixed solution , after reacting at room temperature for 5 hours, the product was repeatedly precipitated and purified with cold n-hexane, and set aside; 60 mL of dichloromethane and 14 mmol of triethylamine were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com