A kind of microporous polymer copolymer membrane material and preparation method thereof

A polymer copolymer and membrane material technology, applied in the field of microporous polymer copolymer membrane material and its preparation, can solve the problems of solubility, flexibility and poor selectivity, so as to improve selectivity and broaden the application field , The effect of simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

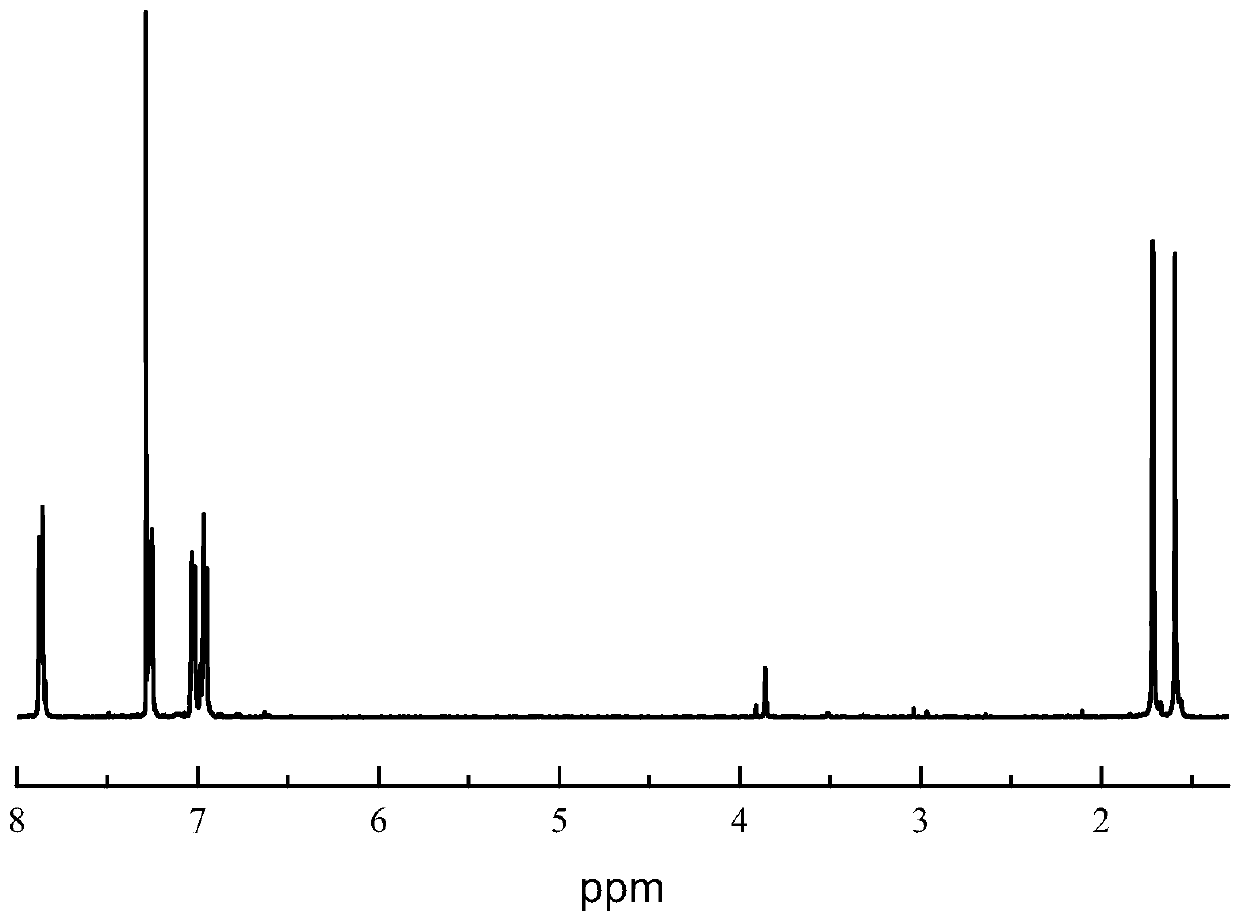

[0044] Dissolve bisphenol A and bis(4-fluorophenyl)sulfone in N,N'-dimethylacetamide, under the protection of inert gas, add potassium carbonate, stir at 50℃~200℃ for 5~20h , adding 3,4-dimethoxyphenol to obtain oligomer A. Wherein, the ratio of bisphenol A and bis(4-fluorophenyl) sulfone is 1:2~100:101, and the ratio of bisphenol A and 3,4-dimethoxyphenol is 100︰1~1︰1, the dosage of N,N'-dimethylacetamide is 1~100ml per gram of monomer.

[0045] Dissolving methoxy-based polyethersulfone in chloroform, under the protection of inert gas, reacted with boron tribromide for 1-20 hours to obtain hydroxyl-based polyethersulfone. Wherein, the ratio of the amount of methoxy polyethersulfone to boron tribromide is 1:1-1:100, and the amount of chloroform added is 1-100ml per gram of solid.

[0046] Combine the obtained hydroxyl polyethersulfone with 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane and tetrafluoroparaphenylene Dissolve dinitrile in N,N'-dimethylformami...

Embodiment 2

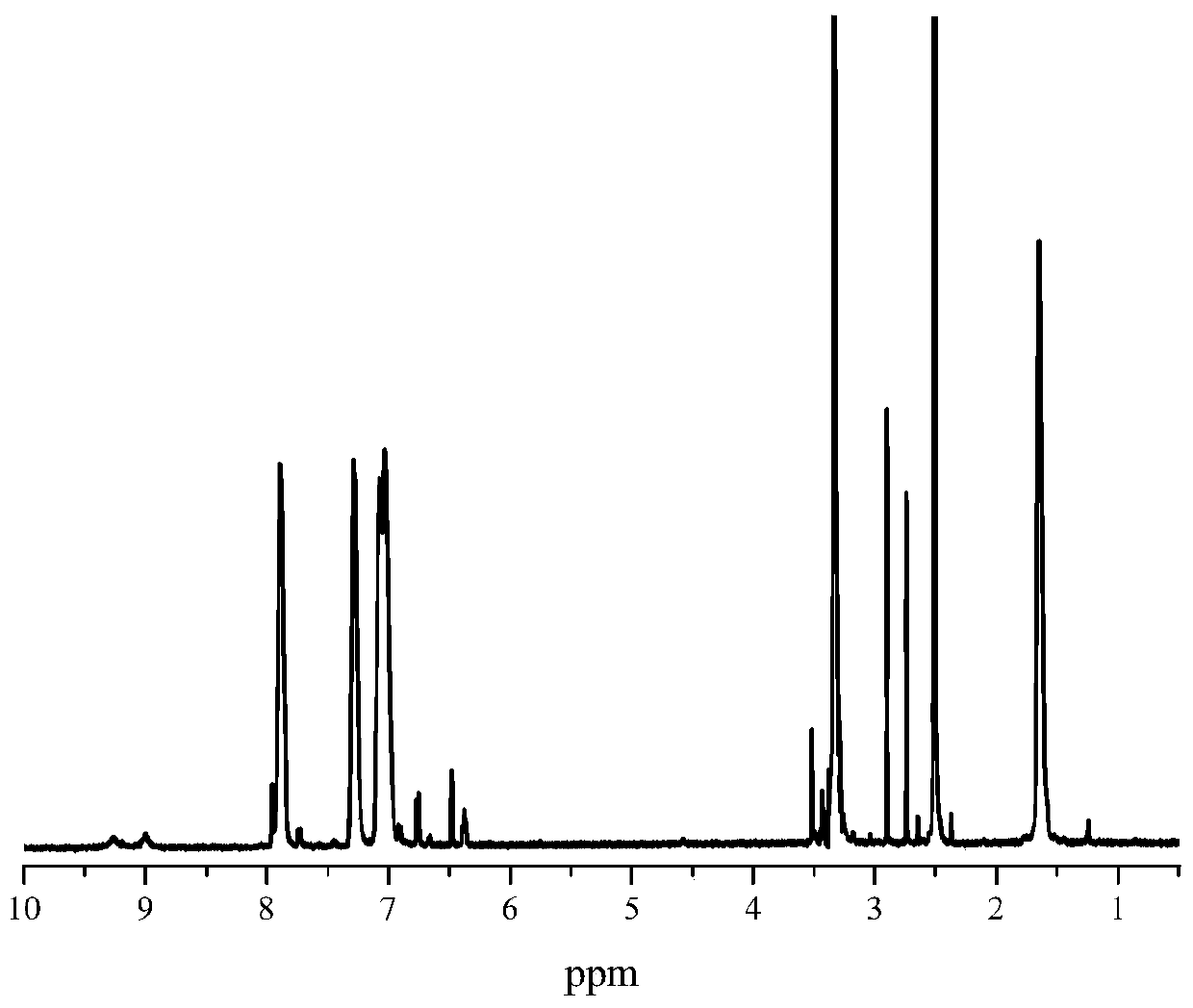

[0052]Dissolve 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane and tetrafluoroterephthalonitrile in N,N' - In dimethylformamide solvent, under the protection of inert gas, and under the action of potassium carbonate, polycondensation reaction is carried out to obtain oligomer fluorine-based self-porous macromolecules. Among them, the amount of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane and tetrafluoroterephthalonitrile The ratio is 1:2~100:110. The dosage of N,N'-dimethylformamide is 1-100ml per gram of monomer.

[0053] Dissolve the oligomer fluorine-based polymer with microporous polymers and the hydroxyl-based polyethersulfone in Example 1 in N,N'-dimethylformamide, and add potassium carbonate under the protection of an inert gas to carry out polycondensation reaction Polycondensation reaction is carried out to obtain macromolecule, that is, self-polymerized microporous macromolecular block copolymer (PIM-1-b-PES) of the target produ...

Embodiment 3

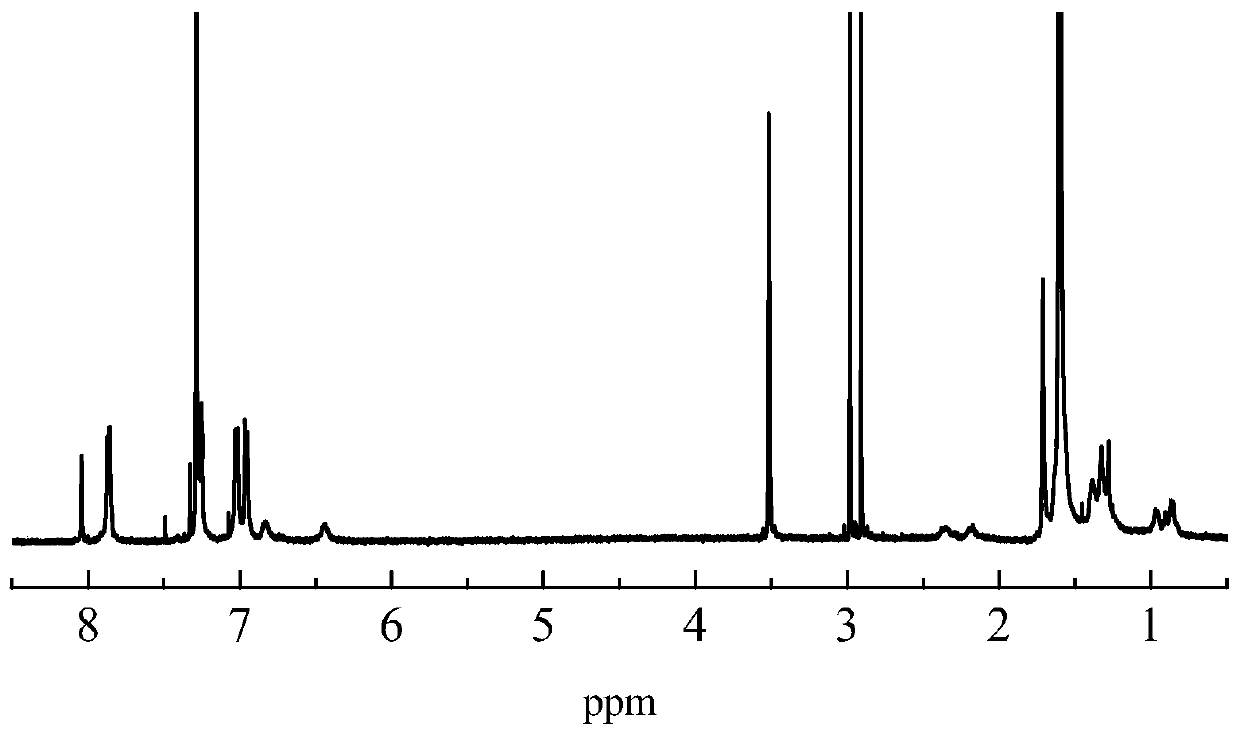

[0059] Dissolve tetramethylbisphenol A and bis(4-fluorophenyl)sulfone in N,N'-dimethylacetamide, add potassium carbonate under the protection of inert gas, and stir at 50°C to 200°C for 5 ~20h later, add 3,4-dimethoxyphenol to obtain methoxy tetramethyl polyethersulfone. Wherein, the ratio of tetramethylbisphenol A to bis(4-fluorophenyl) sulfone is 1:2~100:101, the ratio of tetramethylbisphenol A to 3,4-dimethoxyphenol The ratio of the amount of substances is 100:1-1:1, and the amount of N,N'-dimethylacetamide is 1-100ml per gram of monomer.

[0060] Dissolving methoxy tetramethyl polyether sulfone in chloroform, under the protection of inert gas, reacted with boron tribromide for 1-20 hours to obtain hydroxyl tetramethyl polyether sulfone. Wherein, the ratio of the amount of methoxy tetramethyl polyether sulfone to boron tribromide is 1:1-1:100, and the amount of chloroform added is 1-100ml per gram of solid.

[0061] Combine the obtained hydroxyl tetramethyl polyethersulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com