Polyamide-based powdery alloy material and preparation method thereof

A powder alloy and polyamide technology, applied in the field of additive manufacturing, can solve the problems that affect the dimensional stability and mechanical properties of the workpiece, there is no powder alloy material application, and the dry impact performance of polyamide is poor, so as to improve the dimensional stability properties, improve physical and mechanical properties, and reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a polyamide-based powder alloy material, comprising the following steps:

[0037] (1) Dry the above-mentioned polyamide alloy under a vacuum condition of 60-100° C. for 4-10 hours, then add the above-mentioned materials into a high-speed mixer to mix uniformly to obtain a mixed material, and put the mixed material into a twin-screw extruder to carry out Extrusion and granulation to obtain polyamide alloy particle samples;

[0038] (2) Put the polyamide alloy particles into the low-temperature refrigeration equipment for low-temperature pulverization to obtain polyamide alloy powder, pass through a 100-mesh sieve to obtain 97-99.8wt.% of the polyamide alloy powder, and the powder flow aid is 0.1-2wt.%. %, the powder antioxidant is 0.1-1 wt. %, and the powder is added into a high-speed mixer and mixed uniformly to obtain a polyamide alloy powder material suitable for selective laser forming.

[0039] The present ...

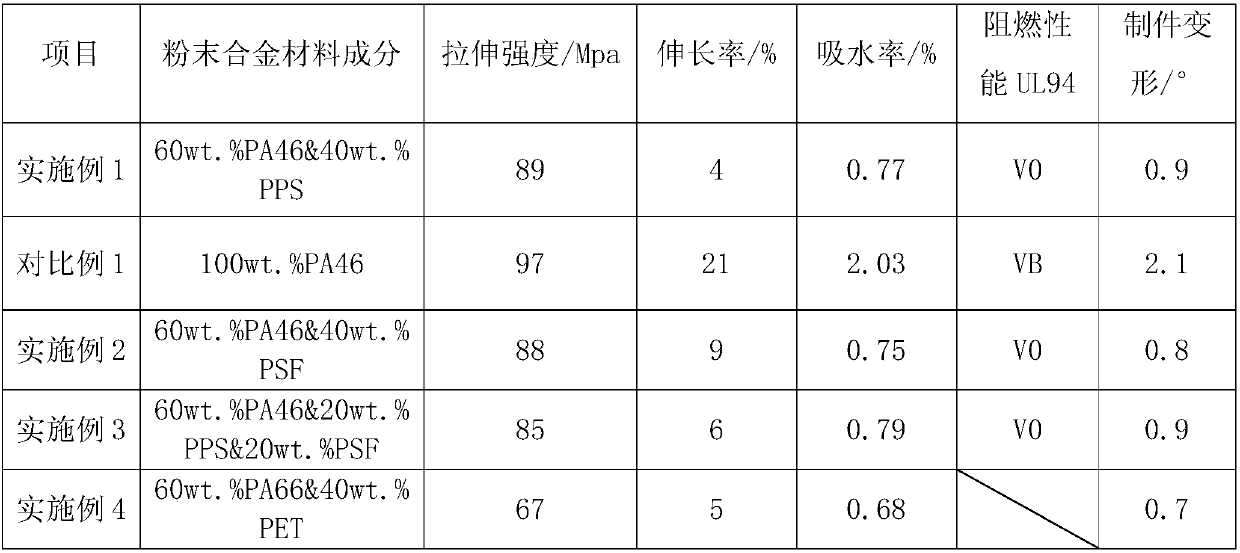

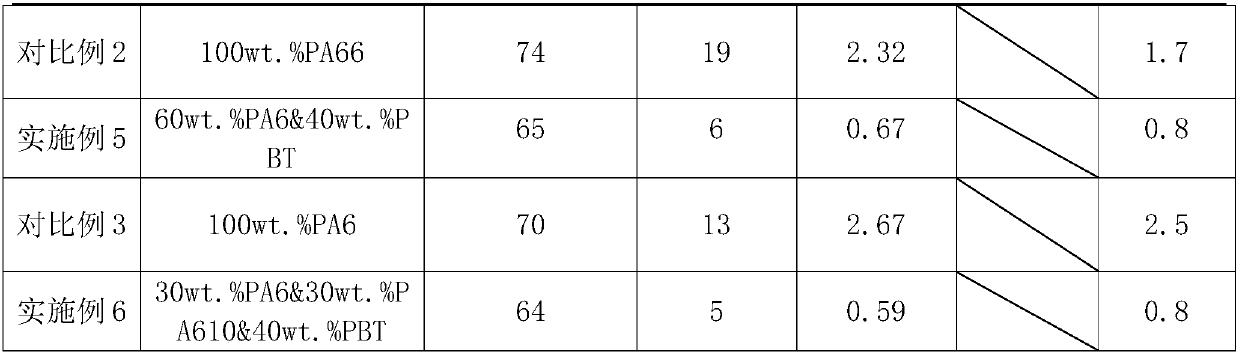

Embodiment 1

[0041] (1) Put 4kg PPS resin, 5.5kg PA46 resin, 0.5kg styrene-maleic anhydride (SMA) alternating copolymer into a vacuum drying oven at 80°C for drying for 6h, add the above materials into a high-speed mixer and mix uniformly, Then, the mixed material is put into a twin-screw extruder for extrusion and granulation, and the obtained granules are subjected to low-temperature freezing and pulverization.

[0042] (2) Mix 7.92kg of the above powder, 0.04kg of fumed silica, and 0.04kg of 2,6-di-tert-butyl-4-methyl-phenol to obtain a PA46 and PPS powder alloy material suitable for selective laser sintering.

[0043] (3) The above powders were sintered on Hunan Farsoon Hi-Tech ST252 selective laser sintering equipment, and the obtained sintered parts were tested for mechanical properties and water absorption. The results are shown in Table 1.

Embodiment 2

[0049] (1) Put 4kg PSF resin, 5.5kg PA46 resin, 0.5kg styrene-maleic anhydride (SMA) alternating copolymer into a vacuum drying oven at 80°C for drying for 6h, add the above materials into a high-speed mixer and mix uniformly, Then, the mixed material is put into a twin-screw extruder for extrusion and granulation, and the obtained granules are subjected to low-temperature freezing and pulverization.

[0050] (2) Mix 7.92kg of the above powder, 0.04kg of fumed silica, and 0.04kg of 2,6-di-tert-butyl-4-methyl-phenol to obtain a PA46 and PSF powder alloy material suitable for selective laser sintering.

[0051] (3) The above powders were sintered on Hunan Farsoon Hi-Tech ST252 selective laser sintering equipment, and the obtained sintered parts were tested for mechanical properties and water absorption. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com