Nano-emulsion type efficient cleanup additive

A technology of nanoemulsion and drainage aid, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of low flowback rate, lower gas phase relative permeability, hindering shale gas desorption and gas migration, etc. problem, to achieve the effect of low damage and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

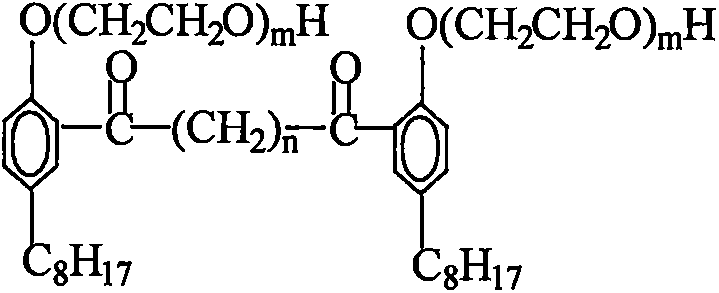

[0013] Synthesis method: add 24% of gemini surfactant dialkylphenol polyoxyethylene ether (m=8, n=2), 5% of solubilizer methanol, and 16% of oil phase dihydrojasmone into the reactor; mix well , heating to keep the temperature in the reactor at 60-70°C, then adding 48% water and 7% sodium chloride; reacting under stirring for 1-2 hours to obtain a light yellow transparent liquid.

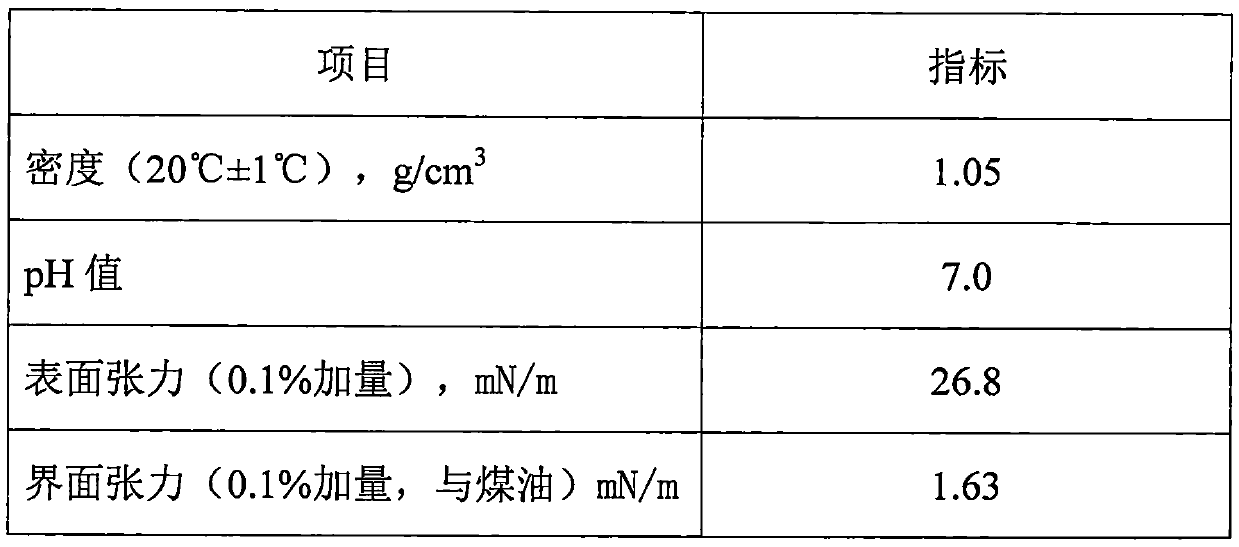

[0014] The sample is subjected to a performance test, and the results are shown in Table 1:

[0015] project

Embodiment 2

[0017] Synthesis method: add 26% of gemini surfactant dialkylphenol polyoxyethylene ether (m=10, n=2), 6% of solubilizer isopropanol, and 18% of oil phase dihydrojasmone into the reactor; Mix evenly, heat to keep the temperature in the reactor at 60-70°C, then add 42% water and 8% sodium chloride; react under stirring for 1-2 hours to obtain a light yellow transparent liquid.

[0018] The sample is subjected to a performance test, and the results are shown in Table 2:

[0019] project

Embodiment 3

[0021] Synthesis method: add 20% of gemini surfactant dialkylphenol polyoxyethylene ether (m=12, n=4), 6% of solubilizer ethanol, and 15% of oil phase dihydrojasmone into the reactor; mix well , heating to keep the temperature in the reactor at 60-70°C, then adding 51% water and 8% calcium chloride; reacting for 1-2 hours under stirring to obtain a light yellow transparent liquid.

[0022] This sample is carried out performance test, and the results are shown in Table 3:

[0023]

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com