Solvent-fee synthesis process for organic dithiopyrophosphate flame retardant and apparatus thereof

A technology of dithiopyrophosphate and synthesis process, which is applied in the fields of organic chemistry, compounds of group 5/15 elements of the periodic table, chemical instruments and methods, etc., which can solve the problem of excessive use of solvents and other additives and unsustainable flame retardant effect , increase costs and other issues, to achieve the effect of reducing the workload of employees, improving the degree of automation and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

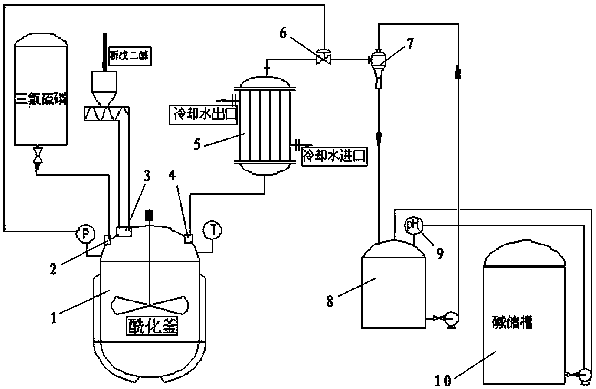

[0022] Such as figure 1 The shown solvent-free synthesis equipment of organic dithiopyrophosphate flame retardant has a reactor, and the reactor has a neopentyl glycol inlet, a phosphorus trichloride inlet, a process water inlet, an exhaust gas outlet, or There is a pyridine inlet; the tail gas outlet of the reaction kettle is connected to a condenser and a jet pump in sequence, and the dilute alkali circulation tank is connected to the jet pump and communicated with each other to circulate and absorb hydrogen chloride tail gas.

[0023] An alkali storage tank is also provided, and the alkali storage tank is connected with the dilute alkali circulation tank to replenish the lye consumed therein. A supply pump is connected between the dilute alkali circulation tank and the alkali storage tank, a pH meter is installed in the dilute alkali circulation tank, and the pH meter and the supply pump form a chain adjustment relationship.

[0024] use as figure 1 The equipment shown us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com