Ceramic and plastic composite preparing method and electronic device shell

A technology of composite materials and plastic materials, which is applied in the field of preparation of ceramic and plastic composite materials, can solve the problems of low bonding strength between ceramic shells and plastic composites, failure to pass the drop test and waterproof test of electronic products, etc., to achieve enhanced bonding, easy Effect of operation, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

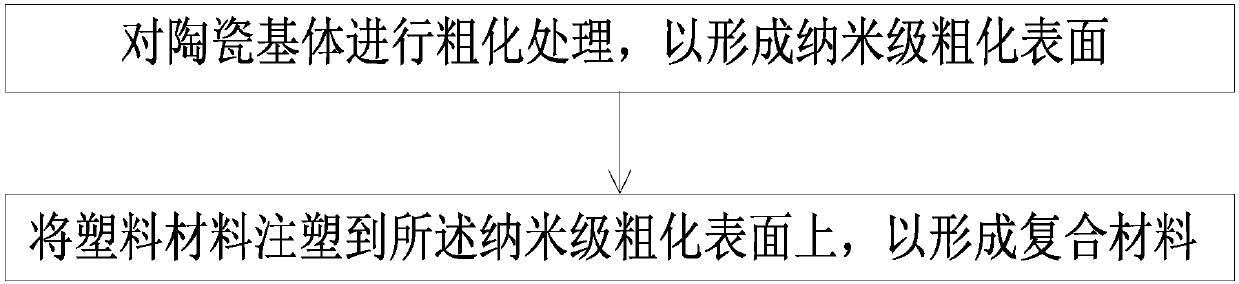

[0029] Such as figure 1 Shown, the preparation method of this ceramic and plastic composite material comprises the following steps:

[0030] S1. Roughening the ceramic substrate to form a nanoscale roughened surface.

[0031] Optionally, the ceramic matrix is selected from one of zirconia ceramics, alumina ceramics, silicon oxide ceramics, titanium oxide ceramics, magnesium oxide ceramics, calcium oxide ceramics, silicon nitride ceramics, boron nitride ceramics and silicon carbide ceramics or A variety of composite ceramics. The above-mentioned ceramic matrix has high strength and low shrinkage after molding.

[0032] Certainly, the type of the ceramic matrix is not limited thereto, and those skilled in the art can select according to actual needs.

[0033] Nano-scale roughened surface, that is, a surface with nano-sized convex and concave structures formed on the ceramic substrate. During injection molding, the plastic material can be filled into the pores of the nano...

Embodiment 1

[0053] In a specific embodiment of the present invention. First, prepare a zirconia ceramic substrate with a thickness of 1.5 mm, a length of 40 mm, and a width of 18 mm; after mechanical grinding, degreasing and degreasing, a clean surface is obtained.

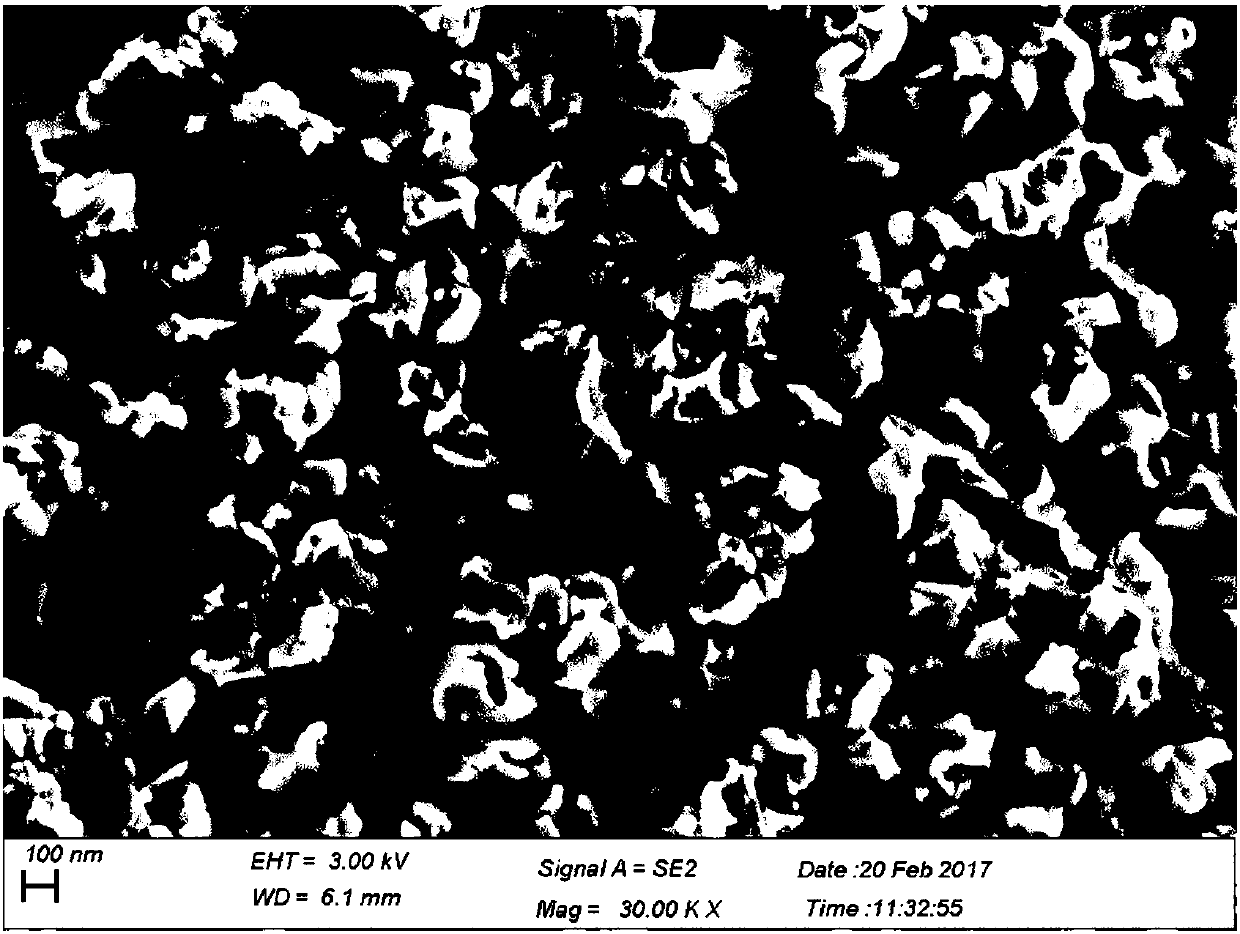

[0054] Then, the zirconia ceramic substrate was placed in an acidic solution of 20% sulfuric acid, and corroded at a temperature of 80°C for 2400s. After taking it out, rinse it with deionized water and dry it. After drying, SEM testing was carried out. Such as figure 2 As shown, a nanoscale roughened surface is formed on the zirconia ceramic substrate.

[0055] Finally, the roughened zirconia ceramic matrix is placed in an injection mold, and the plastic material containing 80% polysuccinate and 20% glass fiber is injected into the roughened surface using an injection molding machine, wherein the injection pressure It is 100MPa, the injection speed is 180mm / s, and the mold temperature is 120°C. The zirconia ceramic m...

Embodiment 2

[0057] In this example, the acidic solution uses 10% hydrofluoric acid to corrode the zirconia ceramic substrate for 300 seconds at 65° C., and a nanoscale roughened surface is also obtained.

[0058] In this example, the plastic material, injection molding conditions were the same as in Example 1. After testing, the bonding strength between the plastic material and the zirconia ceramic matrix is about 40.0Mpa.

[0059] According to another embodiment of the present invention, a casing of an electronic device is provided. Electronic devices can be, but are not limited to, mobile phones, tablets, laptops, earphones, smart watches, etc.

[0060] The shell is prepared according to the preparation method of the ceramic and plastic composite material provided by the invention. The housing is configured to enclose and form the receiving cavity. The side of the housing close to the accommodating cavity is made of plastic material. The side of the shell away from the containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com