Preparation method for antibacterial and anti-pollution polymer separation membrane based on surface grafting

A surface grafting and separation membrane technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of insufficient modifier coverage and poor modification efficiency, achieving high success rate and easy operation , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

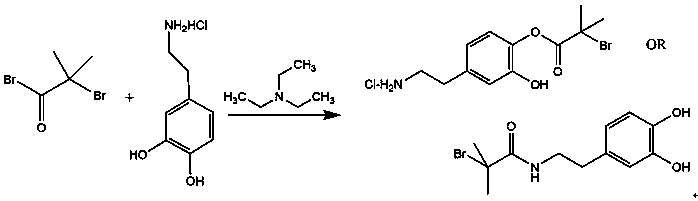

[0030] (1) Soak commercial polyvinylidene fluoride membranes in isopropanol aqueous solution for 30 min, rinse with deionized water, and soak in deionized water for 12 h; dissolve 800 mg of dopamine hydrochloride in 40 mL of N,N-dimethylacetamide After degassing, add 0.26 mL of 2-bromoisobutyryl bromide and 0.3 mL of triethylamine, stir to make it fully react to obtain solution I, the reaction process is as follows figure 1 shown;

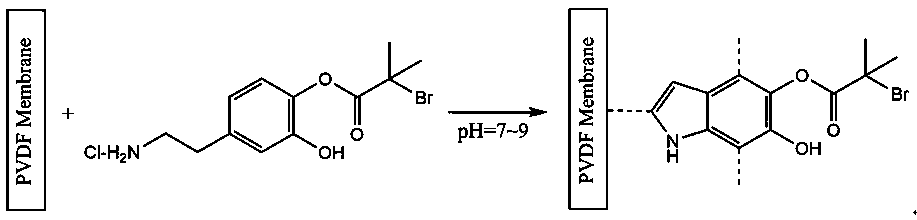

[0031] (2) Mix the solution I with the buffer, and immediately pour it into the mold where the polymer separation membrane is placed for reaction to obtain the polymer separation membrane of the grafted initiator. The polymerization process of the initiator on the membrane is as follows: figure 2 shown;

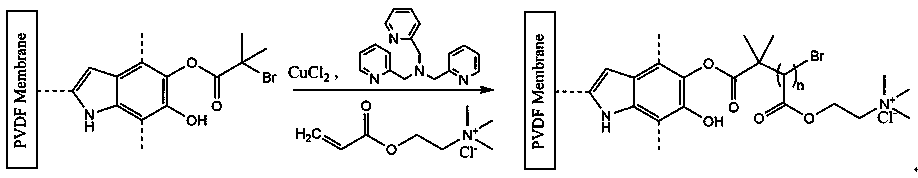

[0032] (3) Add 6 mL of acryloyloxyethyltrimethylammonium chloride, 0.004 g of copper chloride, and 0.028 g of tris(2-pyridylmethyl)amine into the film of the grafting initiator, seal the film for shading, and remove oxygen before adding 0.4 g a...

Embodiment 2

[0036](1) Soak commercial polyvinylidene fluoride membranes in isopropanol aqueous solution for 30 min, rinse with deionized water, and soak in deionized water for 12 h; dissolve 800 mg of dopamine hydrochloride in 40 mL of N,N-dimethylacetamide After degassing, add 0.4mL 2-bromoisobutyryl bromide and 0.4mL triethylamine, stir to make it fully react to obtain solution I, the reaction process is as follows figure 1 shown;

[0037] (2) Mix the solution I with the buffer, and immediately pour it into the mold where the polymer separation membrane is placed for reaction to obtain the polymer separation membrane of the grafted initiator. The polymerization process of the initiator on the membrane is as follows: figure 2 shown;

[0038] (3) Add 6 mL of acryloyloxyethyltrimethylammonium chloride, 0.004 g of copper chloride, and 0.028 g of tris(2-pyridylmethyl)amine into the film of the grafting initiator, seal the film for shading, and remove oxygen before adding 0.4 g ascorbic ac...

Embodiment 3

[0042] (1) Soak commercial polyvinylidene fluoride membranes in isopropanol aqueous solution for 30 min, rinse with deionized water, and soak in deionized water for 12 h; dissolve 800 mg of dopamine hydrochloride in 40 mL of N,N-dimethylacetamide After degassing, add 0.26 mL of 2-bromoisobutyryl bromide and 0.3 mL of triethylamine, stir to make it fully react to obtain solution I, the reaction process is as follows figure 1 shown;

[0043] (2) Mix the solution I with the buffer, and immediately pour it into the mold where the polymer separation membrane is placed for reaction to obtain the polymer separation membrane of the grafted initiator. The polymerization process of the initiator on the membrane is as follows: figure 2 shown;

[0044] (3) Add 9 mL of acryloyloxyethyltrimethylammonium chloride, 0.004 g of copper chloride and 0.028 g of tris(2-pyridylmethyl)amine to the film of the grafting initiator, seal the film with light-shielding, and remove oxygen. Add 0.4 g asco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com