Efficient heat-resistant antibacterial gelatin-based TG enzyme meat product adhesive as well as preparation method and application thereof

A gelatin-based, adhesive technology, applied in the application, ultra-high pressure food processing, food ingredients as emulsifiers and other directions, can solve the problems of affecting the senses, impurities are easy to block the film, safety hazards and other problems, to reduce time costs, improve Food safety, the effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

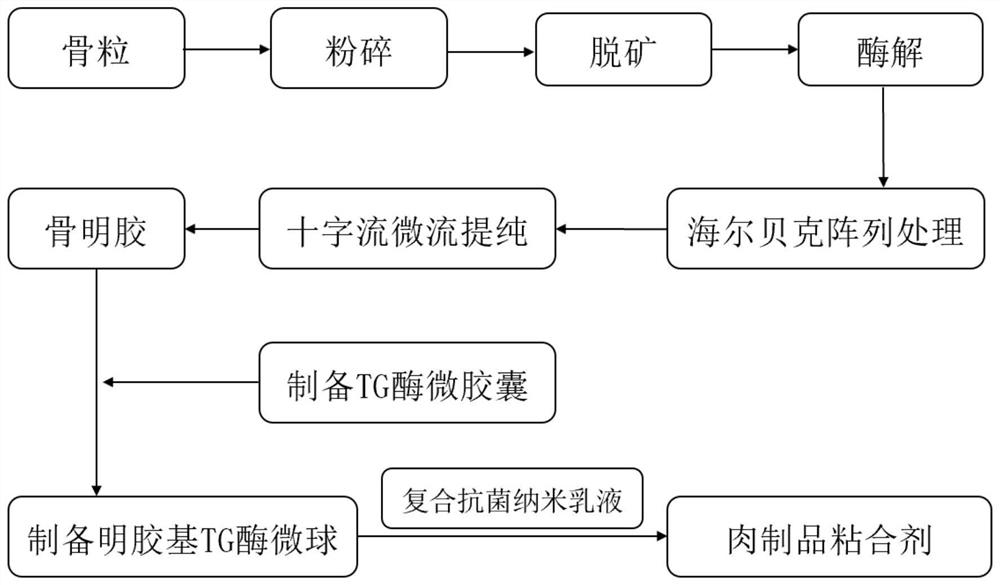

[0069] (1) Glue extraction: use defatted pork bone pellets as raw material, crush and sieve to obtain 500g of bone powder with a particle size of <0.6mm; prepare 4.5L of 1mol / L dilute hydrochloric acid, mix it with bone powder, and add 60U / g of pepsin. At 35°C, the ultrasonic power was set to 250W, and the demineralization and enzymatic hydrolysis were carried out for 2 hours; the mixture was heated to 60°C, the pH of the gel was extracted to be 5, and the gel was extracted for 2 hours.

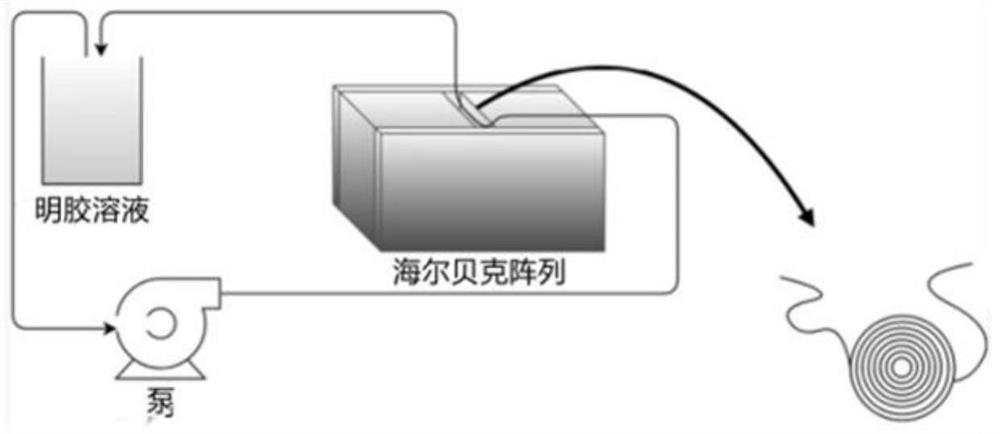

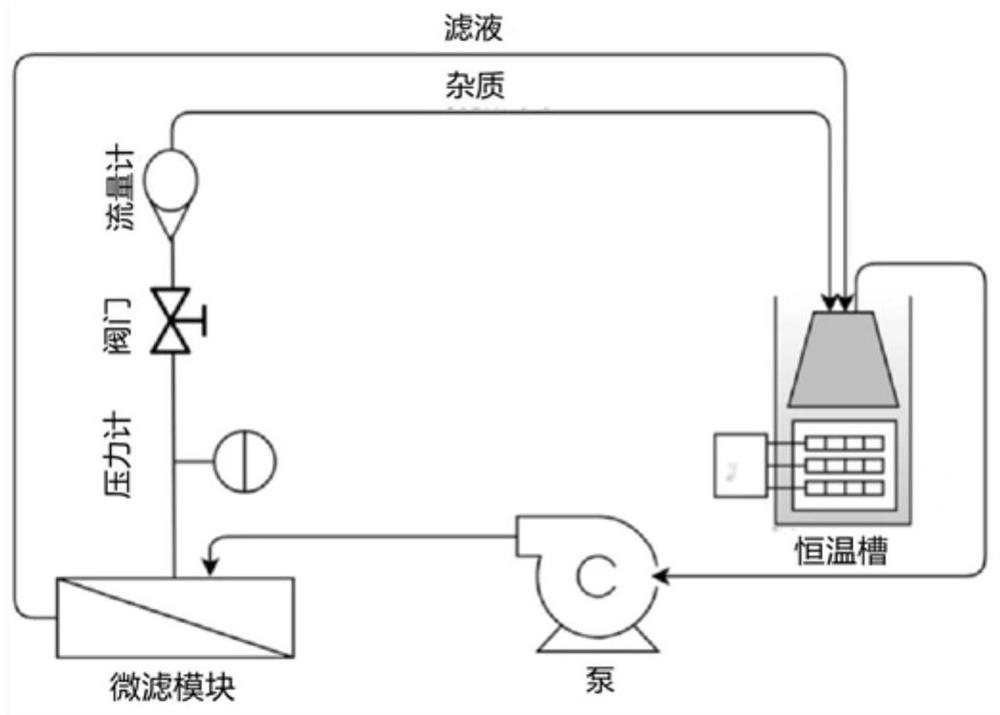

[0070] (2) Purification: first use three layers of gauze, and coarsely filter to remove large particles of impurities; then import it into a stainless steel coil tube with a diameter of 5mm, construct a Halbeck array with a magnetic flux of 1.34T, conduct magnetic induction on the gelatin for 2 hours through a permanent magnetic field, and finally perform a cross Flow microfiltration further removes tiny impurities until high-purity gelatin is obtained. The flow rate of the crude gelatin ext...

Embodiment 2

[0077] (1) Gum extraction: take defatted pork bone grains as raw material, grind and sieve to obtain 500 g of bone powder with a particle diameter of <0.6 mm. ; Configure 4.5L of 1mol / L dilute hydrochloric acid, mix it evenly with bone meal, and then add 40U / g of pepsin. At 40°C, the ultrasonic power was set to 250W, and the demineralization and enzymatic hydrolysis were carried out for 2 hours; the mixture was heated to 60°C, the pH of the gel was extracted at 5, and the gel was extracted for 3 hours.

[0078] (2) Purification: Purify the proposed gelatin. First use three layers of gauze, coarsely filter to remove large particles of impurities; then introduce them into a stainless steel coil with a diameter of 5mm to build a Halbach array with a magnetic flux of 1.34T, conduct magnetic induction on the gelatin for 2 hours through a permanent magnetic field, and finally perform cross-flow microfiltration for further removal Minor impurities until high-purity gelatin is obtain...

Embodiment 3

[0085] (1) Glue extraction: use defatted pork bone pellets as raw material, crush and sieve to obtain 500g of bone powder with a particle size of <0.6mm; configure 4.5L of 1mol / L dilute hydrochloric acid, mix it with bone powder evenly, and add 50U / g of pepsin. At 40°C, the ultrasonic power was set to 250W, and demineralization and enzymatic hydrolysis were performed for 2 hours. The mixture was heated to 60°C, the gel pH was 5.5, and the gel extraction time was 2.5h.

[0086] (2) Purification: Purify the proposed gelatin. First use three layers of gauze, coarsely filter to remove large particles of impurities; then introduce them into a stainless steel coil with a diameter of 5mm to build a Halbach array with a magnetic flux of 1.34T, conduct magnetic induction on the gelatin for 2 hours through a permanent magnetic field, and finally perform cross-flow microfiltration for further removal Minor impurities until high-purity gelatin is obtained. The flow rate of the crude ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com