Stannous chloride master batch, and preparation method and application thereof

A technology of stannous chloride mother and stannous chloride is applied in the field of stannous chloride master batch and its preparation, which can solve the problems of inaccurate measurement, sticking on the wall of equipment, excessive cross-linking of rubber and plastic products, etc., and achieves excellent results. Heat resistance and aging resistance, reducing powder flying, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also includes a preparation method of stannous chloride masterbatch, comprising the following steps,

[0019] (1) take various raw materials by weight ratio of tin protochloride masterbatch component;

[0020] (2) Place the raw materials in step (1) in the mixer and mix for 10-30min;

[0021] (3) Add the mixture obtained in step (2) to granulate in a twin-screw machine, and the screw speed is set to 200-1000r / min; after setting the temperature in each temperature zone, extrude and pelletize after passing through a 50-mesh filter screen to obtain Stannous chloride masterbatch.

[0022] Further, in the step (3), the temperature in the temperature zone is set to a temperature of 120-160°C in the first zone, a temperature in the second zone of 150-180°C, a temperature in the third zone of 140-170°C, a temperature in the fourth zone of 150-180°C, and a temperature in the fifth zone of 170°C. -190°C, the temperature in the sixth zone is 180-200°C, and ...

Embodiment approach 1

[0025] The preparation method steps are as follows:

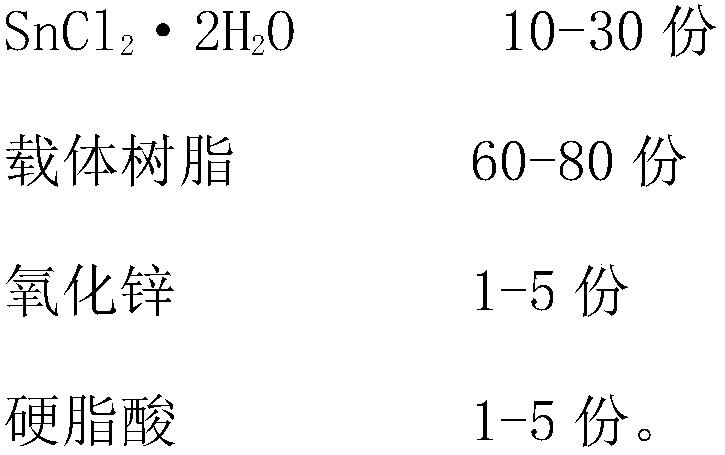

[0026] (1) Take raw materials by the following parts by weight:

[0027]

[0028] (2) Place the raw materials of step (1) in a high-speed mixer and mix for 15 minutes;

[0029] (3) Put the mixture obtained in step (2) into a twin-screw machine for granulation, the screw speed is set to 200r / min, the temperature is 120°C in the first zone, 140°C in the second zone, 150°C in the third zone, and 150°C in the fourth zone. The temperature in the zone is 150°C, the temperature in the fifth zone is 170°C, the temperature in the sixth zone is 180°C, and the temperature in the seventh zone is 180°C. After passing through a 50-mesh filter, extrude and pelletize to obtain stannous chloride masterbatch. And the masterbatch is used to produce TPV (PP / EPDM dynamically vulcanized thermoplastic elastomer), that is, the weight ratio of TPV raw material and stannous chloride masterbatch is 100:1 to produce TPV, and the test results of TP...

Embodiment approach 2

[0031] The preparation method steps are as follows:

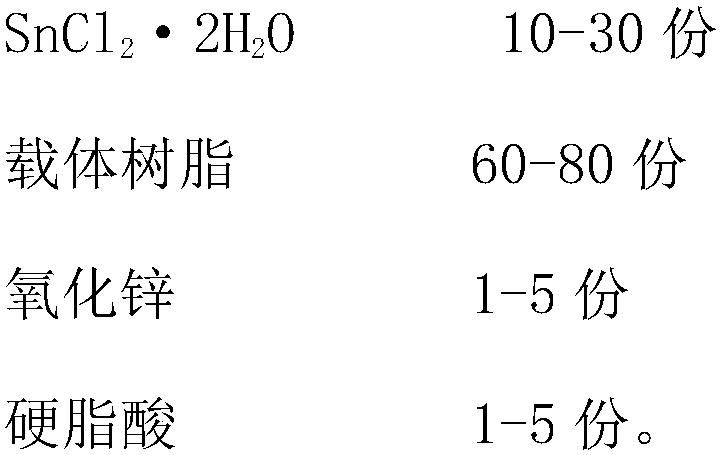

[0032] (1) Take raw materials by the following parts by weight:

[0033]

[0034] (2) Place the raw materials of step (1) in a high-speed mixer and mix them for 20 minutes;

[0035] (3) Put the mixture obtained in step (2) into a twin-screw machine for granulation, the screw speed is set to 500r / min, the temperature is 160°C in the first zone, 170°C in the second zone, 170°C in the third zone, and 170°C in the fourth zone. The temperature in the zone is 180°C, the temperature in the fifth zone is 190°C, the temperature in the sixth zone is 200°C, and the temperature in the seventh zone is 200°C. After passing through a 50-mesh filter, extrude and pelletize to obtain stannous chloride masterbatch. And the masterbatch is used to produce TPV (PP / EPDM dynamically vulcanized thermoplastic elastomer), that is, the weight ratio of TPV raw material and stannous chloride masterbatch is 100:1 to produce TPV, and the test results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com