A niobate reversible photochromic material and preparation method thereof

A technology of photochromic materials and niobate, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems such as the limitation of color change diversity, the limitation of practical applications, and the limited types of inorganic photochromic materials. The method is simple and easy, the equipment requirements are low, and the effect of fatigue resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the general formula LiNbO 3 , Weigh Li respectively 2 CO 3 and Nb 2 o 5 , with a molar ratio of 1:1, mixed thoroughly and ground until uniform, then put into a corundum crucible, then put into a high-temperature tube furnace, kept at 1050°C in an air environment for 5 hours, and finally cooled naturally with the furnace to room temperature, and then took out the sample Grind again to powder to obtain a white powdery niobate reversible photochromic material.

[0034] After the niobate reversible photochromic material prepared in Example 1 of the present invention is excited by 254nm ultraviolet light, its color gradually changes from white to gray, and the color gradually returns to the original white after being irradiated by sunlight. It can be repeated infinitely and has the advantage of good fatigue resistance.

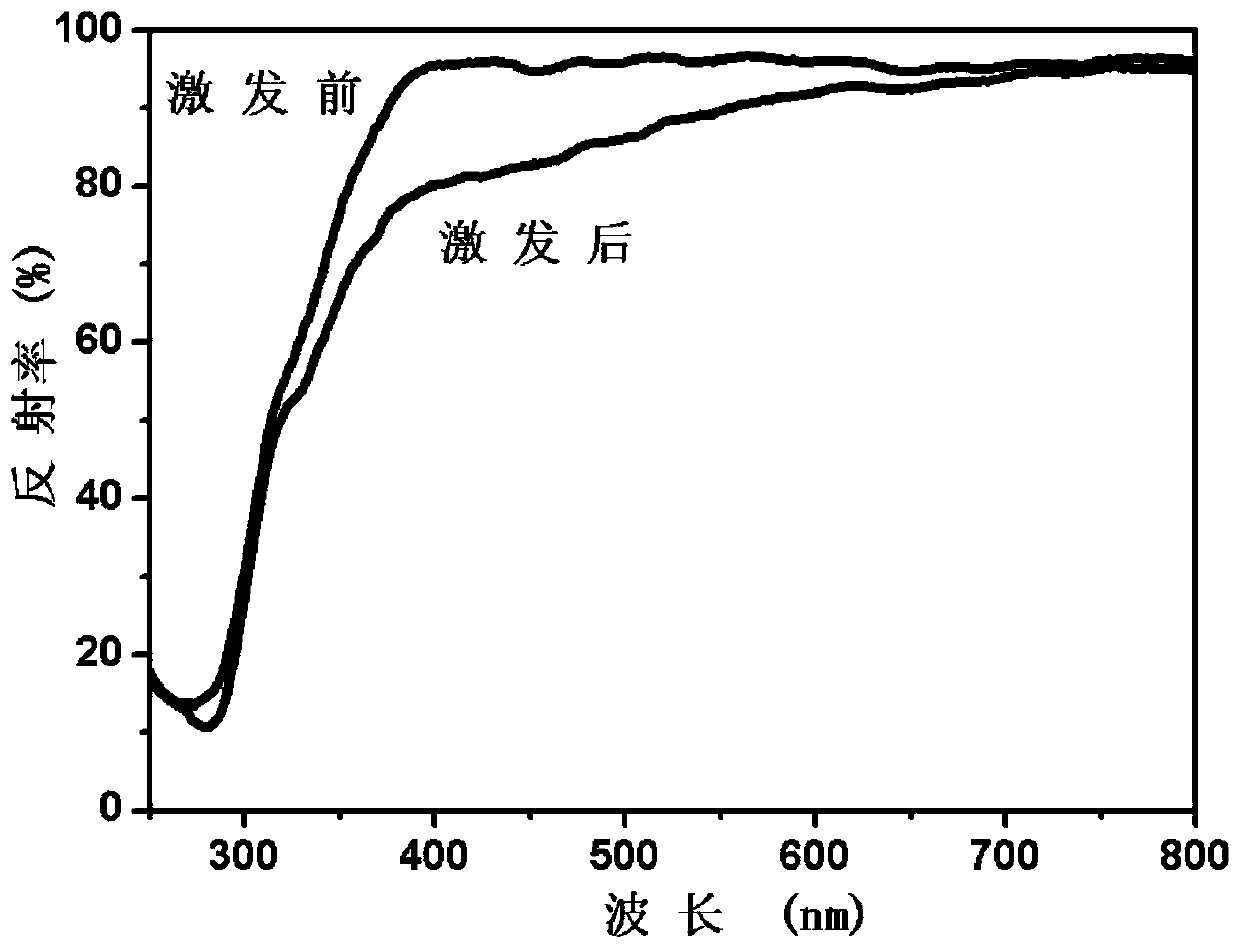

[0035] The LiNbO prepared by the present embodiment 1 was analyzed by a UV-visible spectrophotometer 3 Niobate reversible photochromic ma...

Embodiment 2

[0037] According to the general formula Li 0.995 NbO 3 :0.005Y 3+ , Weigh Li respectively 2 CO 3 , Nb 2 o 5 and Y 2 o 3, the molar ratio is 0.995:1:0.005, fully mixed and ground until uniform, then put into a corundum crucible, then put into a high-temperature tube furnace, keep warm in the air environment at 1050°C for 5h, and finally cool down to room temperature naturally with the furnace The sample was taken out and ground to powder again to obtain a white powdery niobate reversible photochromic material.

[0038] After the reversible photochromic material prepared in Example 2 of the present invention is excited by 254nm ultraviolet light, its color gradually changes from white to gray, and the color gradually returns to the original white after being irradiated by sunlight. The reversible discoloration process can be unlimited repetitions, has the advantage of good fatigue resistance.

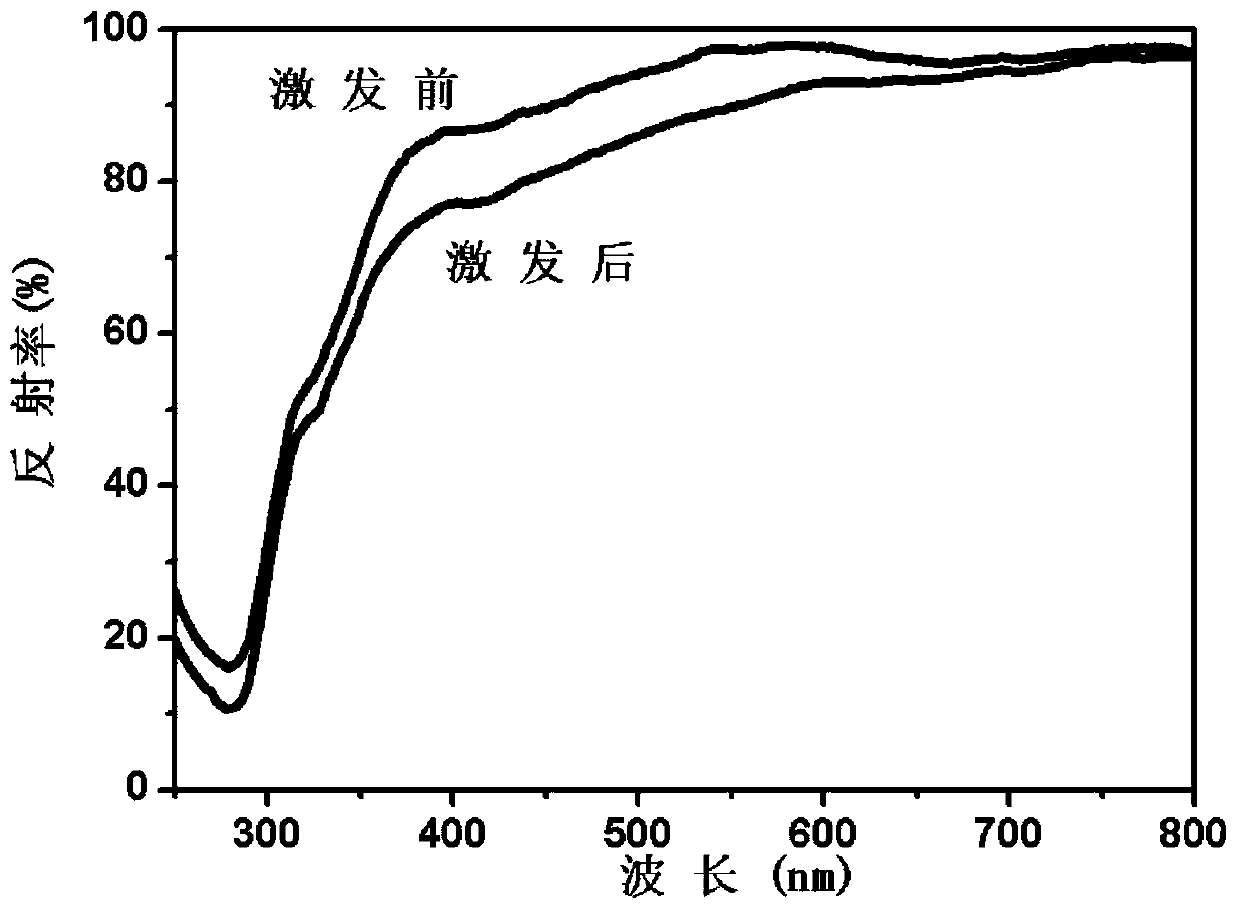

[0039] The niobate reversible photochromic material prepared in Example 2 is...

Embodiment 3

[0041] According to the general formula Li 0.995 NbO 3 :0.005Sm 3+ , Weigh Li respectively 2 CO 3 , Nb 2 o 5 and Sm 2 o 3 , the molar ratio is 0.995:1:0.005, fully mixed and ground until uniform, then put into a corundum crucible, then put into a high-temperature tube furnace, keep warm in the air environment at 1050°C for 5h, and finally cool down to room temperature naturally with the furnace The sample was taken out and ground to powder again to obtain a white powdery niobate reversible photochromic material.

[0042] After the reversible photochromic material prepared in Example 3 of the present invention is excited by 254nm ultraviolet light, its color gradually changes from white to gray, and the color gradually returns to the original white after being irradiated by sunlight. This reversible photochromic process can be infinitely repeated. Repeated, has the advantage of good fatigue resistance.

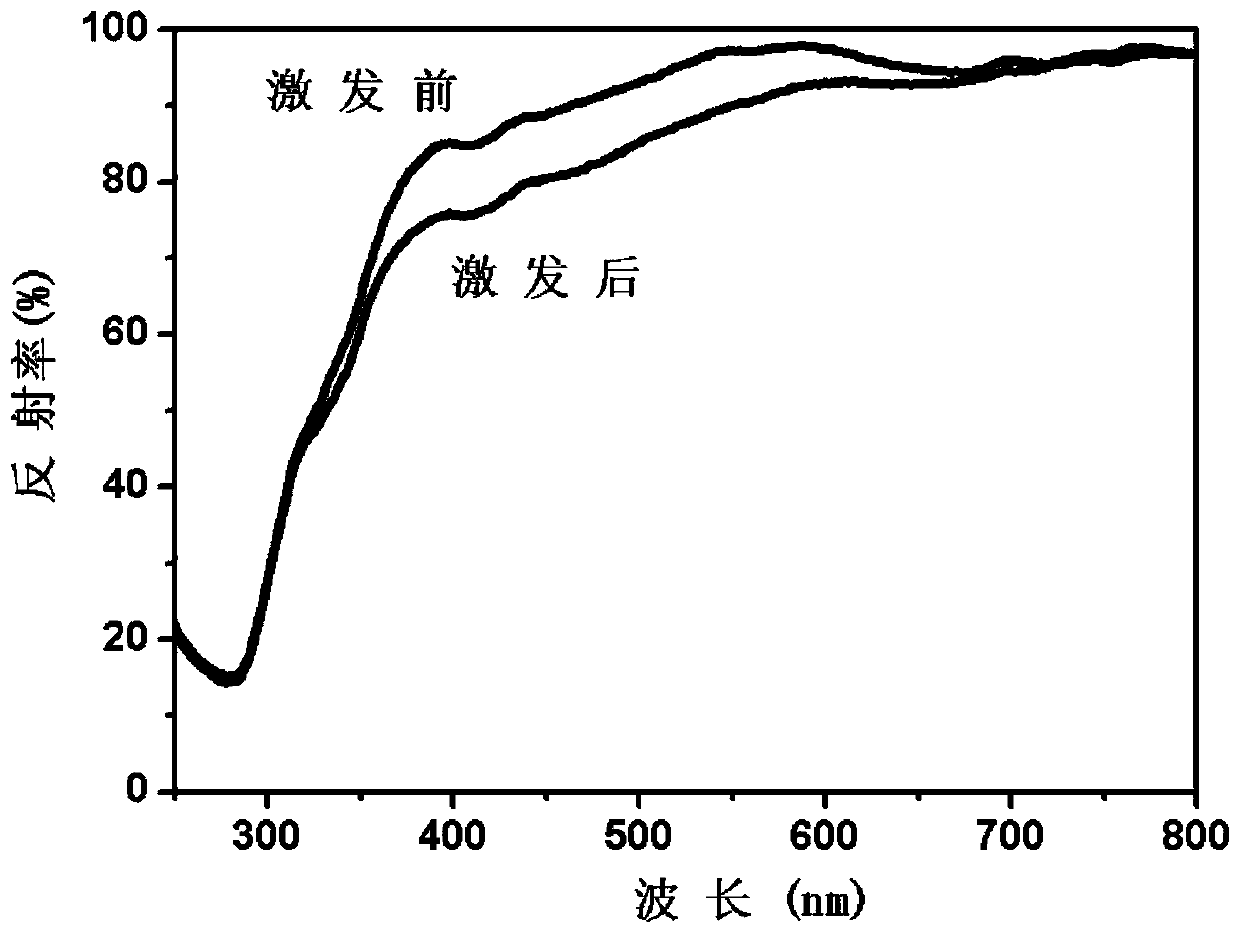

[0043] The niobate reversible photochromic material prepared in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com