Walnut oil extraction method based on supercritical CO2

A carbon dioxide, supercritical technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production. Active substances, improving extraction efficiency, preventing spoilage and rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

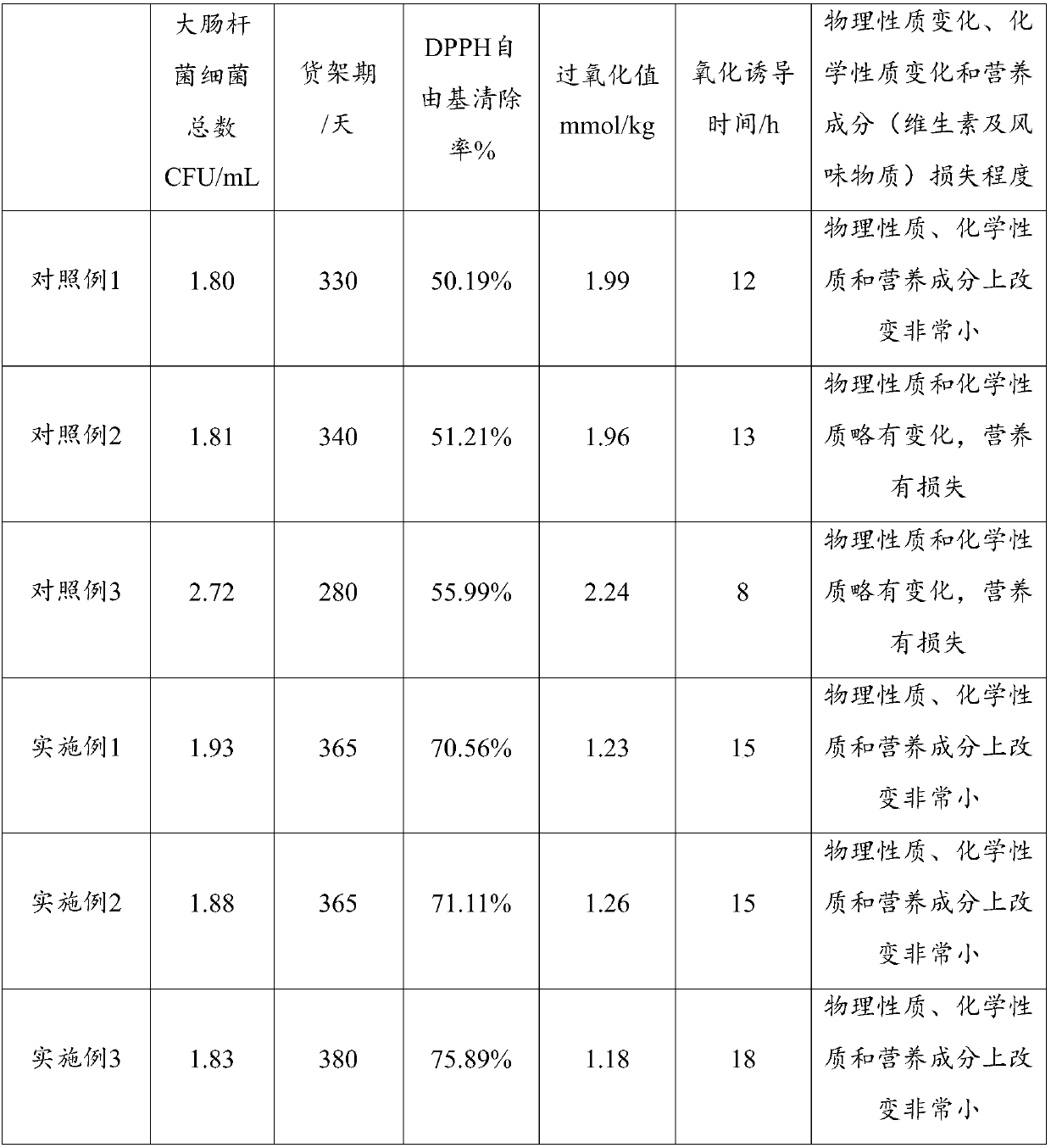

Examples

Embodiment 1

[0026] The present embodiment provides a kind of method that supercritical carbon dioxide extracts walnut oil, and concrete method is:

[0027] 1. To obtain walnut kernels after shelling walnuts, freeze the walnut kernels in liquid nitrogen at -100°C for 7 minutes, and then thaw them in microwave at 75°C for 8 minutes to remove the skin; 60 mesh sieves, and then the walnut powder obtained is subjected to ultrasonic treatment for 12 minutes under the conditions that the ultrasonic power is 450W, the ultrasonic temperature is 32°C, and the ultrasonic frequency is 20KHz;

[0028] 2. Put the ultrasonically treated walnut powder into the supercritical CO 2 In the extraction kettle, in CO 2 The supercritical CO 2 Extract for 45min to obtain crude oil and cake;

[0029] 3. The crude oil is subjected to pulsed electric field treatment for 100 μs under the conditions of electric field strength of 20kV / cm, pulse frequency of 300Hz, and pulse flow rate of 50mL / min, and then undergoes ...

Embodiment 2

[0032] The present embodiment provides a kind of method that supercritical carbon dioxide extracts walnut oil, and concrete method is:

[0033] 1. Shell the walnuts to obtain walnut kernels, freeze the walnut kernels in liquid nitrogen at -120°C for 5 minutes, and then thaw them in microwave at 85°C for 5 minutes to remove the skin; 60-mesh sieve, then the obtained walnut powder was subjected to ultrasonic treatment for 8 minutes under the conditions that the ultrasonic power was 550W, the ultrasonic temperature was 39°C, and the ultrasonic frequency was 25KHz;

[0034] 2. Put the ultrasonically treated walnut powder into the supercritical CO 2 In the extraction kettle, in CO 2 The supercritical CO 2 Extract for 40min to obtain crude oil and cake;

[0035] 3. The crude oil is subjected to pulsed electric field treatment for 80 μs under the conditions of electric field strength of 25kV / cm, pulse frequency of 400Hz, and pulse flow rate of 70mL / min, and then undergoes ultrafin...

Embodiment 3

[0038] The present embodiment provides a kind of method that supercritical carbon dioxide extracts walnut oil, and concrete method is:

[0039] 1. To obtain walnut kernels after shelling walnuts, freeze the walnut kernels in liquid nitrogen for 5 minutes at -100°C, and then thaw them in microwave at 80°C for 6 minutes to remove the skin; 60 mesh sieve, then the walnut powder obtained is subjected to ultrasonic treatment for 10 min under the conditions that the ultrasonic power is 480W, the ultrasonic temperature is 37°C, and the ultrasonic frequency is 25KHz;

[0040] 2. Put the ultrasonically treated walnut powder into the supercritical CO 2 In the extraction kettle, in CO 2 The supercritical CO 2 Extract for 42min to obtain crude oil and cake;

[0041]3. The crude oil is subjected to pulsed electric field treatment for 90 μs under the conditions of electric field strength of 23kV / cm, pulse frequency of 340Hz, and pulse flow rate of 62mL / min, and then undergoes ultrafine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com