High energy storage efficiency ferroelectric polymer matrix dielectric film, preparation method of the same, and application of the same

A technology of ferroelectric polymer and dielectric film, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, etc., can solve the problem that the solution method is not suitable for large-scale production, and achieve the effect of excellent energy storage performance and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

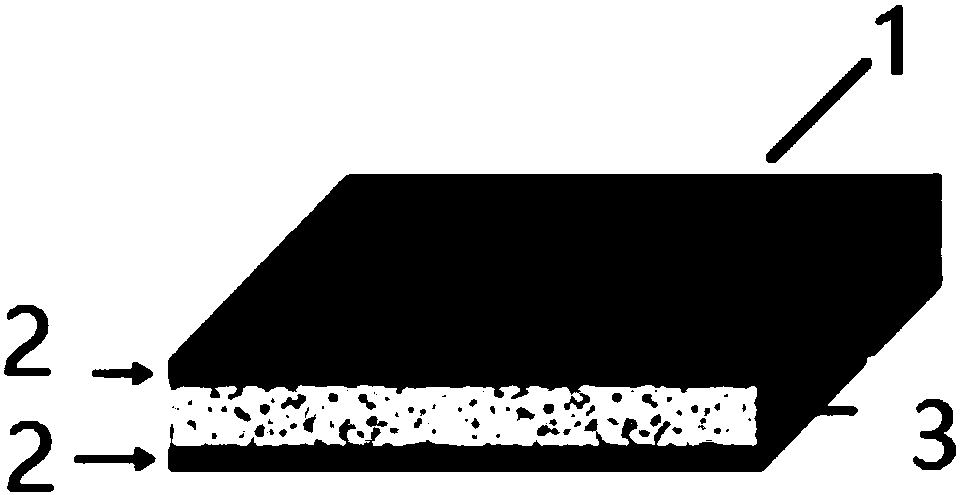

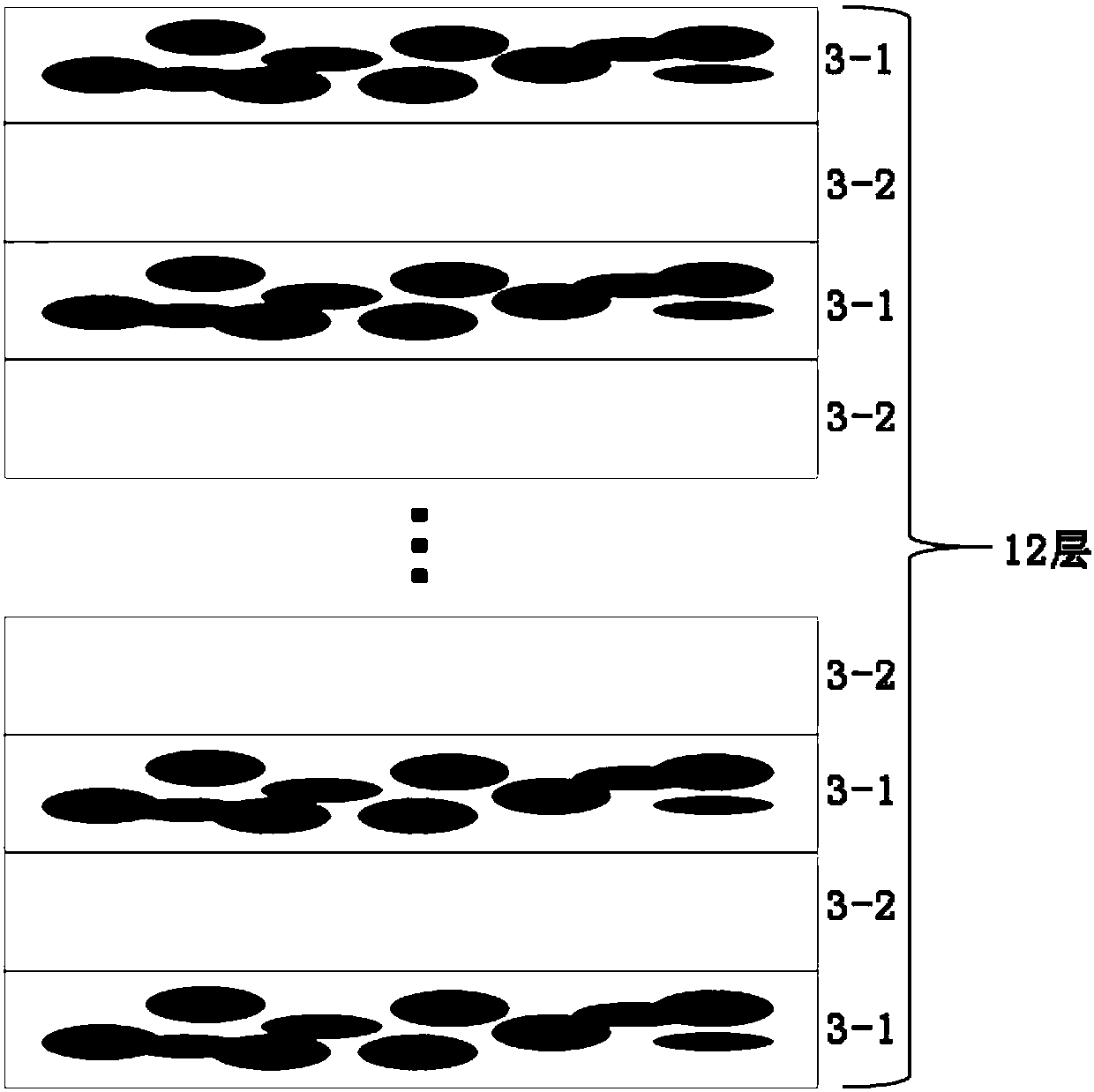

[0049] The present invention also provides a method for preparing the ferroelectric polymer-based dielectric thin film according to the present invention, which includes the following steps:

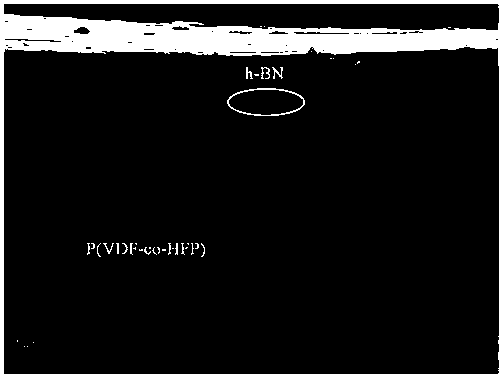

[0050] Step 1), mixing the hexagonal boron nitride h-BN and the vinylidene fluoride-hexafluoropropylene copolymer P(VDF-co-HFP) in an organic solvent according to the ratio to obtain an electrospinning solution 1; Optionally, dissolving the vinylidene fluoride-hexafluoropropylene copolymer P(VDF-co-HFP) in an organic solvent to obtain an electrospinning solution 2;

[0051] Step 2), subjecting the electrospinning solution 1 to high-voltage electrospinning, or alternately performing high-voltage electrospinning on the electrospinning solution 1 and the electrospinning solution 2, to obtain a non-woven spinning body ;

[0052] Step 3), hot pressing the non-woven spinning body, naturally cooling to room temperature, and then quenching to obtain a ferroelectric polymer-based dielectric film...

Embodiment 1

[0065] Ultrasonically disperse h-BN in an organic solvent, sonicate for 10 hours at an ultrasonic power of 250w, and then do the batching according to 99vol%P(VDF-co-HFP)-1vol%h-BN(x=1), where each gram of solid The proportion of powder corresponding to 5 ml of mixed solvent, using acetone and N,N-dimethylformamide (DMF) as mixed solvent, stirring for 12 hours to make spinning solution for later use, the ratio of acetone and DMF in the mixed solvent is 2:3 .

[0066] A homogeneous spun body of polymer nanofilaments was prepared by high-voltage electrospinning. The parameters of the high-voltage electrospinning are: the positive and negative voltage difference is 5.9 kV; the rotation speed of the roller is 290 rpm, and the solution advancing speed is 1 mL per hour. After spinning, the spinning layer was hot-pressed at 190° C. and 490 dpi for 40 minutes, and then cooled down to room temperature naturally. The hot-pressed film was kept at 240° C. for 10 minutes and then quenche...

Embodiment 2

[0069] Ultrasonically disperse h-BN in an organic solvent, sonicate for 10 hours at an ultrasonic power of 250w, and then do the batching according to 97vol%P(VDF-co-HFP)-3vol%h-BN(x=3), wherein each gram of solid The proportion of powder corresponding to 5 ml of mixed solvent, using acetone and N,N-dimethylformamide (DMF) as mixed solvent, stirring for 12 hours to make spinning solution for later use, the ratio of acetone and DMF in the mixed solvent is 2:3 .

[0070] A homogeneous spun body of polymer nanofilaments was prepared by high-voltage electrospinning. The parameters of the high-voltage electrospinning are: the positive and negative voltage difference is 5.8 kV; the rotation speed of the roller is 285 rpm, and the solution advancing speed is 1 mL per hour. After spinning, the spinning layer was hot-pressed at 193° C. and 489 dpi for 40 minutes, and then cooled down to room temperature naturally. The hot-pressed film was kept at 240° C. for 10 minutes and then quenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com