Preparation of selenium-coated tin dioxide/graphene nano composite material and application thereof

A nano-composite material, tin dioxide technology, applied in the direction of non-aqueous electrolyte battery electrodes, electrical components, battery electrodes, etc., can solve the problems of poor rate and cycle performance, and achieve simple preparation methods, cheap raw materials, and excellent sodium storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

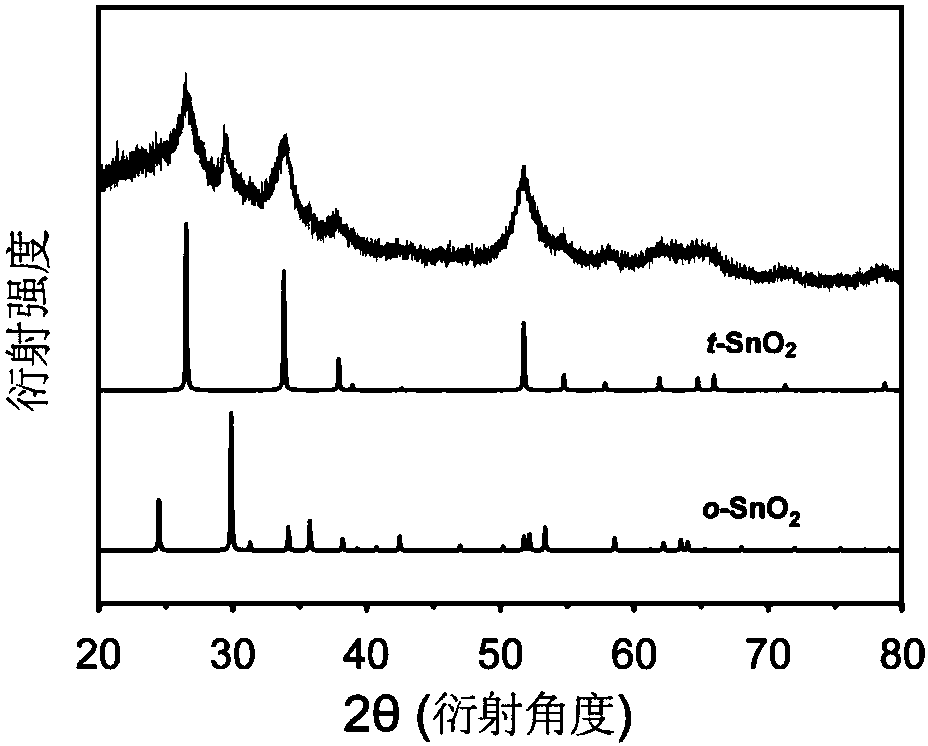

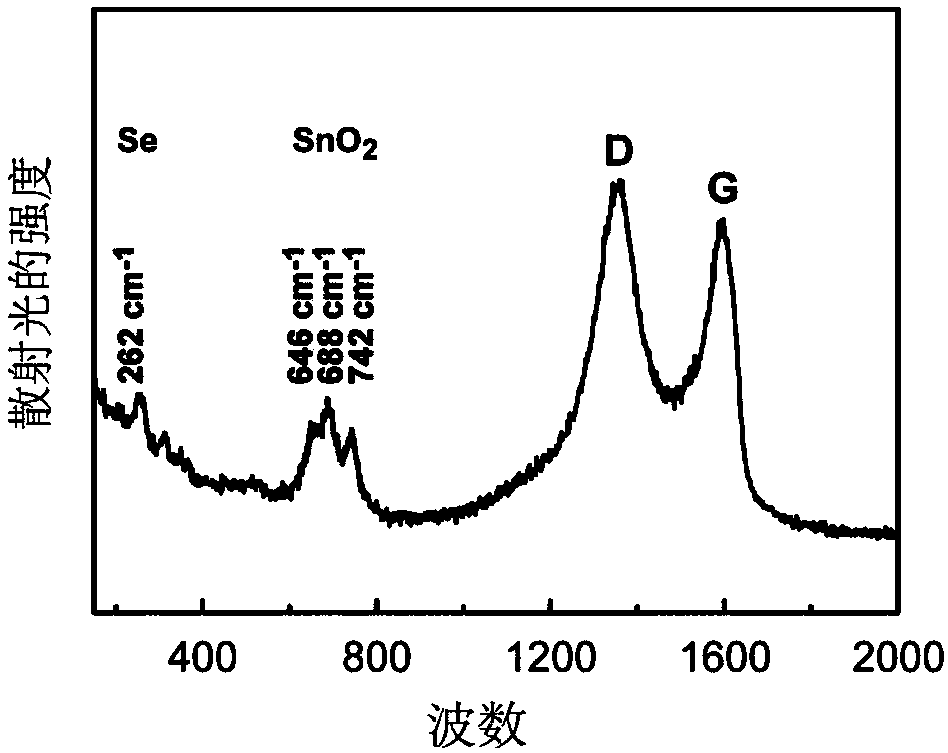

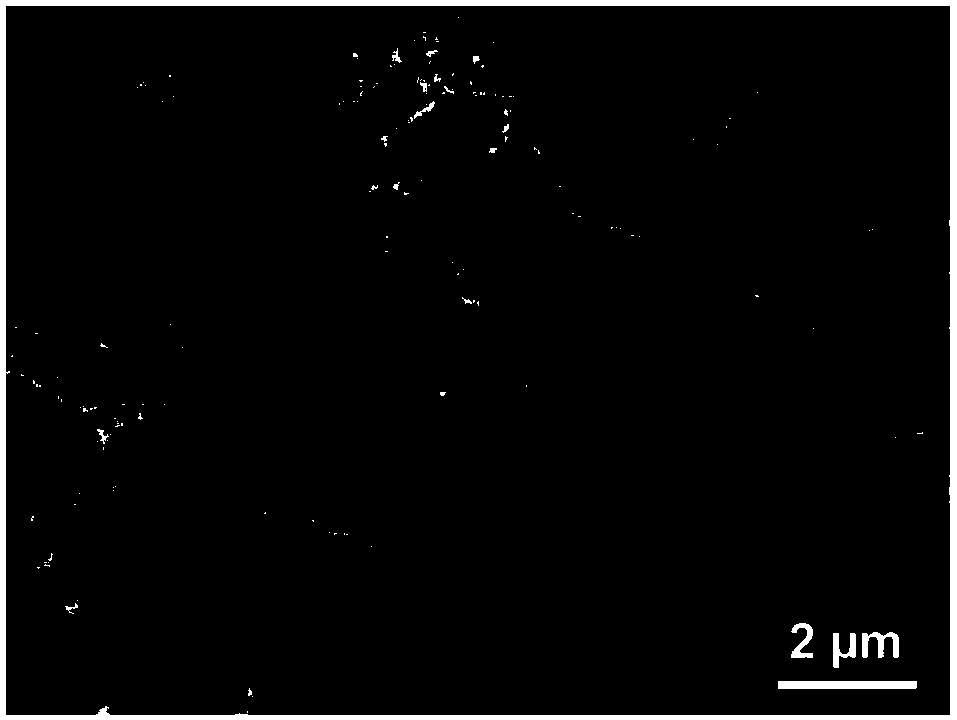

[0021] The preparation of the tin dioxide / graphene nanocomposite material of embodiment 1 selenium coating

[0022] 2.48g of L-tartaric acid was added to 50ml of deionized water, then 295uL of anhydrous tin tetrachloride was added to the solution, and 150mg of graphene oxide aqueous solution (3.5mg mL -1 ), diluted to 300mL; under continuous stirring, add 50mL of 0.1mg mL dropwise to the above suspension -1 Sodium borohydride solution, then ultrasonic 3-6h, centrifuged, washed with deionized water and absolute ethanol, vacuum-dried at 80 ° C; to obtain the intermediate product of Sn; the mass ratio of selenium powder and Sn intermediate product was 2.5:1 Mix evenly, heat up to 400° C., and calcinate for 4 hours; obtain a selenium-coated tin dioxide / graphene nanocomposite material.

Embodiment 2

[0023] The preparation of the tin dioxide / graphene nanocomposite material of embodiment 2 selenium coating

[0024] 2.48g of L-tartaric acid was added to 50ml of deionized water, then 295uL of anhydrous tin tetrachloride was added to the solution, and 150mg of graphene oxide aqueous solution (3.5mg mL -1 ), diluted to 300mL; under continuous stirring, 50mL of 0.3mg mL was added dropwise to the above suspension -1 Sodium borohydride solution, then ultrasonic 3-6h, centrifuged, washed with deionized water and absolute ethanol, vacuum-dried at 80 ° C; to obtain the intermediate product of Sn; the mass ratio of selenium powder and Sn intermediate product was 2.5:1 Mix evenly, heat up to 400° C., and calcinate for 4 hours; obtain a selenium-coated tin dioxide / graphene nanocomposite material.

Embodiment 3

[0025] The preparation of the tin dioxide / graphene nanocomposite material of embodiment 3 selenium coating

[0026] 2.48g of L-tartaric acid was added to 50ml of deionized water, then 295uL of anhydrous tin tetrachloride was added to the solution, and 150mg of graphene oxide aqueous solution (2mg mL -1 ), diluted to 300mL; under constant stirring, add 50mL of 0.2mg mL dropwise to the above suspension -1 Sodium borohydride solution, then ultrasonic 3-6h, centrifuged, washed with deionized water and absolute ethanol, vacuum-dried at 80 ° C; to obtain the intermediate product of Sn; the mass ratio of selenium powder and Sn intermediate product was 2.5:1 Mix evenly, heat up to 400° C., and calcinate for 4 hours; obtain a selenium-coated tin dioxide / graphene nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com