Carbon nanotube conductive paste and preparation method thereof and lithium ion battery

A conductive paste, carbon nanotube technology, applied in battery electrodes, secondary batteries, carbon-silicon compound conductors, etc., can solve the problems of sedimentation, poor dispersion effect, etc., to achieve less sedimentation, good electrical conductivity, and technology. Simple and actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In one embodiment, the preparation method of the carbon nanotube conductive paste at least includes the following steps:

[0040] Step S01. Mixing the dispersant and the solvent so that the dispersant and the solvent are evenly mixed;

[0041] Step S02. Add the conductive functional body to the mixed solution obtained in the step S01 under stirring conditions, and perform pre-dispersion to obtain a premix;

[0042]Step S03. Grinding the premix to obtain carbon nanotube conductive paste.

[0043] In order to better understand the preparation method, the preparation method will be further explained below.

[0044] In step S01, the dispersant and the solvent are firstly mixed, which can save the preparation time of the slurry on the one hand, and on the other hand, enable the carbon nanotubes to be uniformly dispersed in the mixed solution formed by the dispersant and the solvent. When mixing the dispersant and the solvent, the stirring speed is 3000r / min-5000r / min, and ...

Embodiment 1

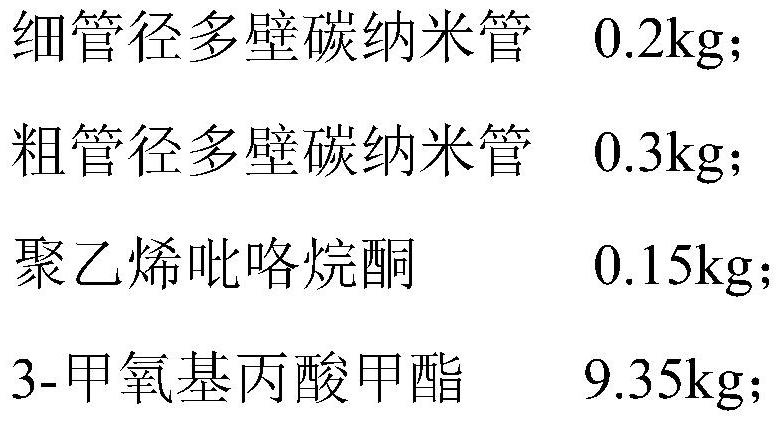

[0056] A carbon nanotube conductive paste, comprising the following components:

[0057]

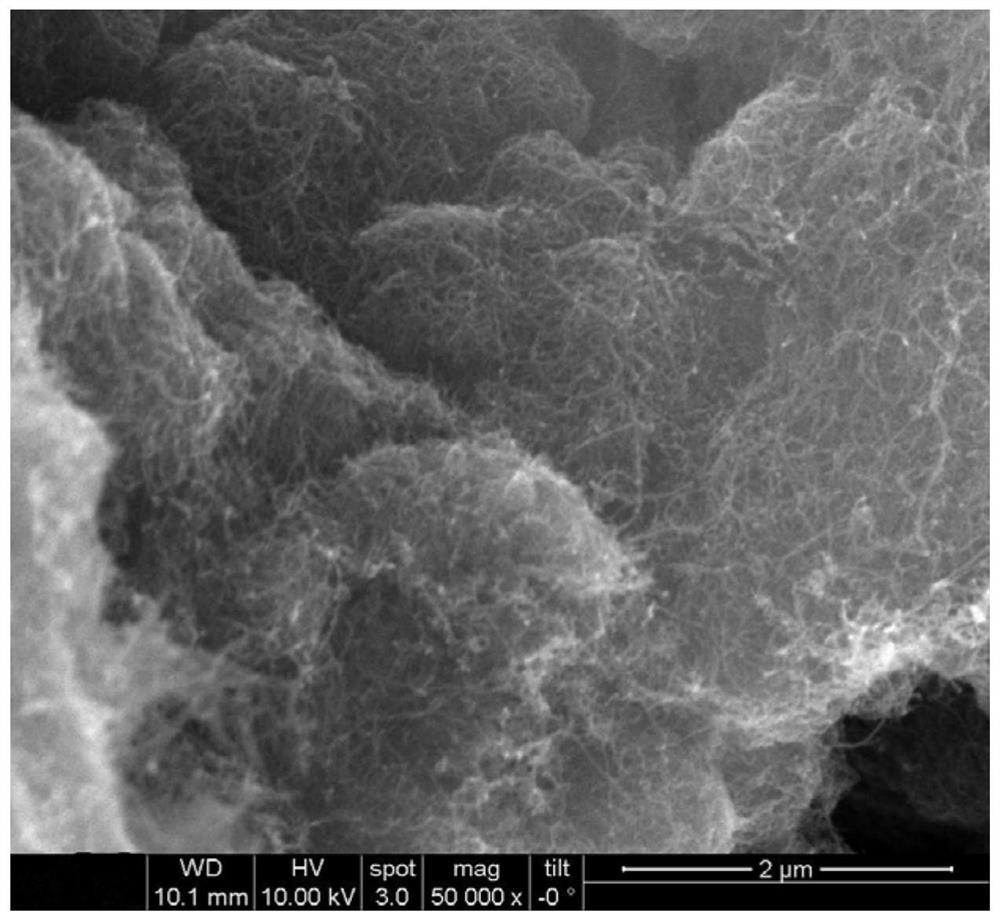

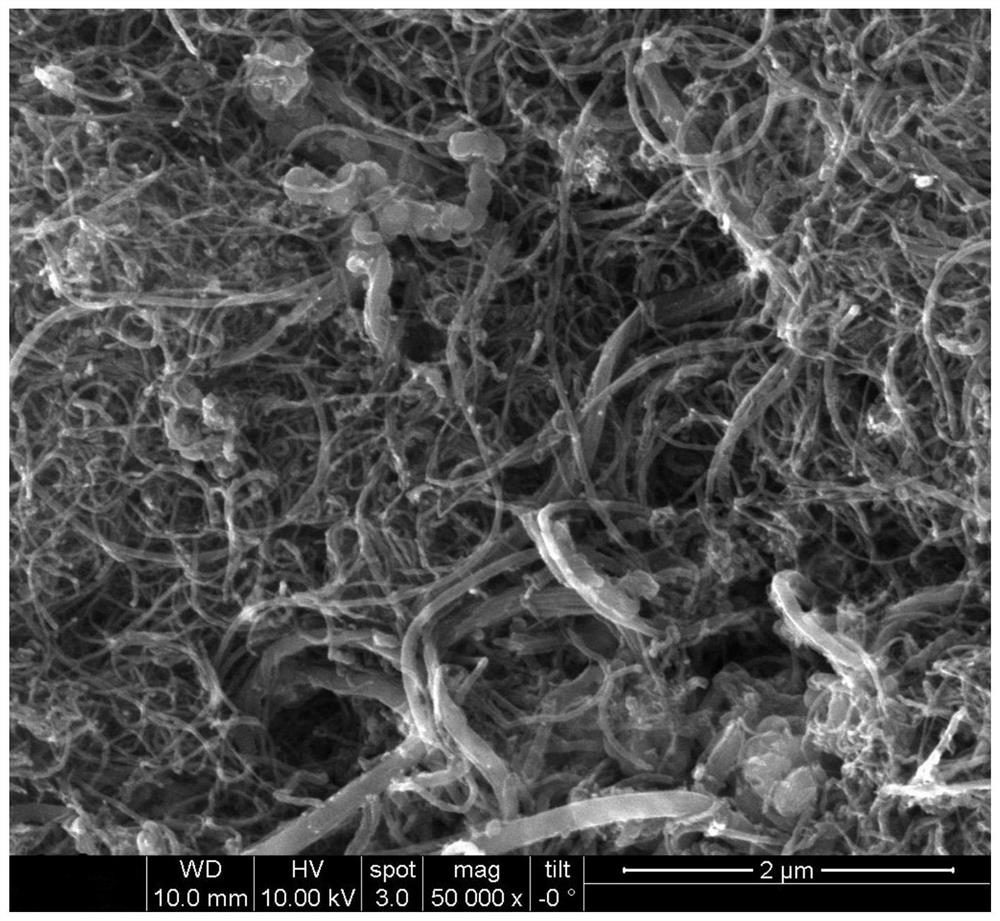

[0058] Wherein, the diameter of the thin-diameter multi-walled carbon nanotubes is 5-40 nm, and the tube length is 30 μm-100 μm; the tube diameter of the thick-diameter multi-walled carbon nanotubes is 60-150 nm, and the tube length is 30 μm-100 μm.

[0059] The preparation method of described carbon nanotube conductive paste comprises the following steps:

[0060] (1) Add 9.35kg of methyl 3-methoxypropionate as a solvent carrier in a 15L container, and add 0.15kg of polyvinylpyrrolidone therein as a dispersant;

[0061] (2) Fully dissolve polyvinylpyrrolidone in methyl 3-methoxypropionate with a high-speed mixer under the condition of 5000r / min to obtain a mixed solution;

[0062] (3) Add 0.2 kg of multi-walled carbon nanotubes with thin tube diameter and 0.3 kg of multi-walled carbon nanotubes with thick tube diameter to the dissolved mixed solution, and then stir for 20 min under ...

Embodiment 2

[0065] A carbon nanotube conductive paste, comprising the following components:

[0066]

[0067] Wherein, the diameter of the thin-diameter multi-walled carbon nanotubes is 5-40 nm, and the tube length is 30 μm-100 μm; the tube diameter of the thick-diameter multi-walled carbon nanotubes is 60-150 nm, and the tube length is 30 μm-100 μm.

[0068] The preparation method of described carbon nanotube conductive paste comprises the following steps:

[0069] (1) Add 4.675kg of methyl 3-methoxypropionate and 4.675kg of ethylene glycol diacetate as a solvent carrier in a 15L container, add 0.15kg of polyvinylpyrrolidone therein as a dispersant;

[0070] (2) Fully dissolve polyvinylpyrrolidone in methyl 3-methoxypropionate and ethylene glycol diacetate with a high-speed mixer under the condition of 5000r / min to obtain a mixed solution;

[0071] (3) Add 0.2 kg of thin-diameter multi-walled carbon nanotubes and 0.3 kg of thick-diameter multi-walled carbon nanotubes to the dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com