Water-based lubricating coating agent for metal material, surface-treated metal material, and method for forming lubricating coating for metal material

A metal material, coating agent technology, applied in the direction of metal material coating process, lubricating composition, base material, etc., to achieve excellent lubricity, prevention of ablation or seizure, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

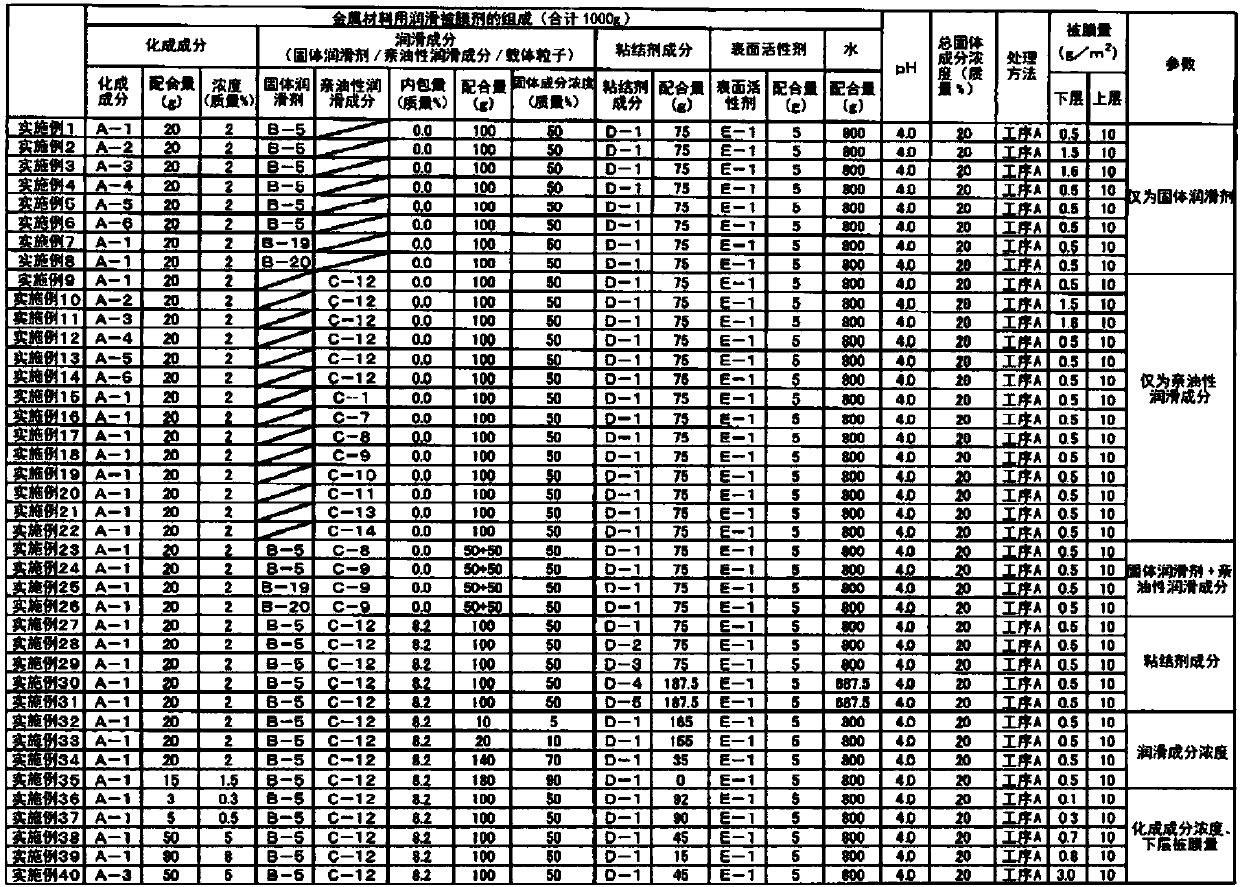

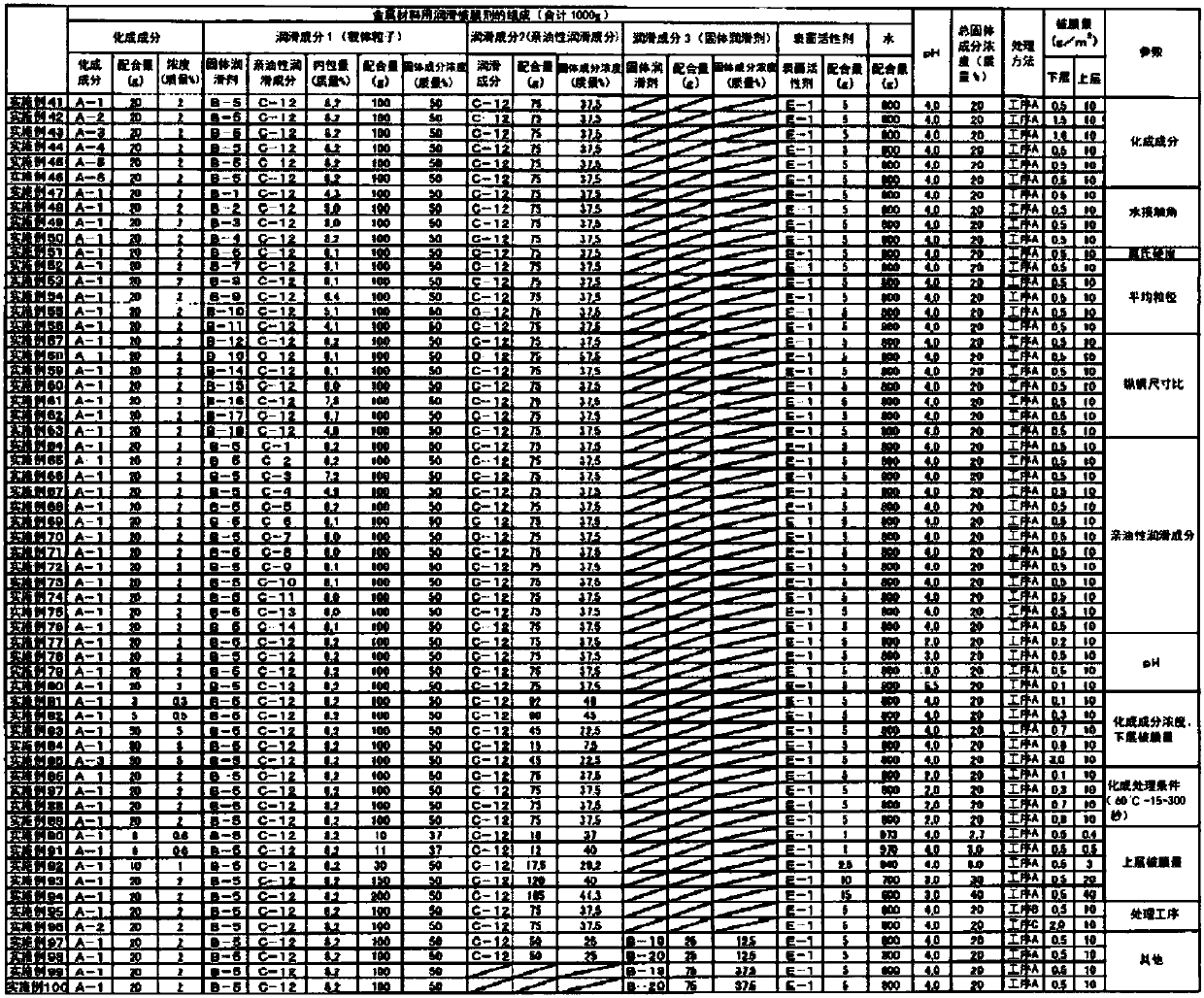

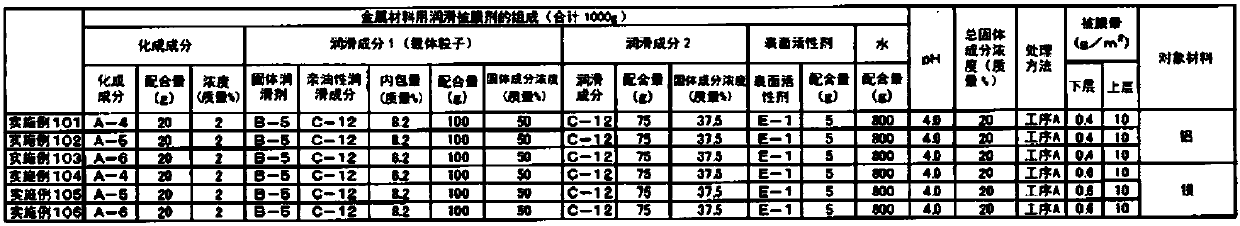

[0102] The effects of the present invention are verified by Examples and Comparative Examples. When producing the lubricating coating agent for metal materials used in the Examples and Comparative Examples, the details of each component are shown below.

[0103] [chemical composition]

[0104] A-1 Phosphate compound: sodium dihydrogen phosphate

[0105] A-2 Phosphate compound: zinc dihydrogen phosphate

[0106] A-3 Oxalic acid compound: oxalic acid

[0108] A-5 Zirconium compound: zirconium hydrofluoride

[0109] A-6 Titanium Compound: Titanium Hydrofluoride

[0110] [Solid lubricants]

[0111] Details of the layered clay mineral (layered clay mineral before the inclusion of the lipophilic lubricating component) and the crystalline inorganic salt used in the test are shown below. The average particle diameter of the solid lubricant was measured by volume-based laser diffraction under the following conditions after redispersing the solid l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solubility coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com