White-reflecting film for large-scale display

A technology of white reflective film and display, applied in the field of white reflective film, can solve the problems of cost and other problems, and achieve the effect of excellent reflection characteristics and not easy thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

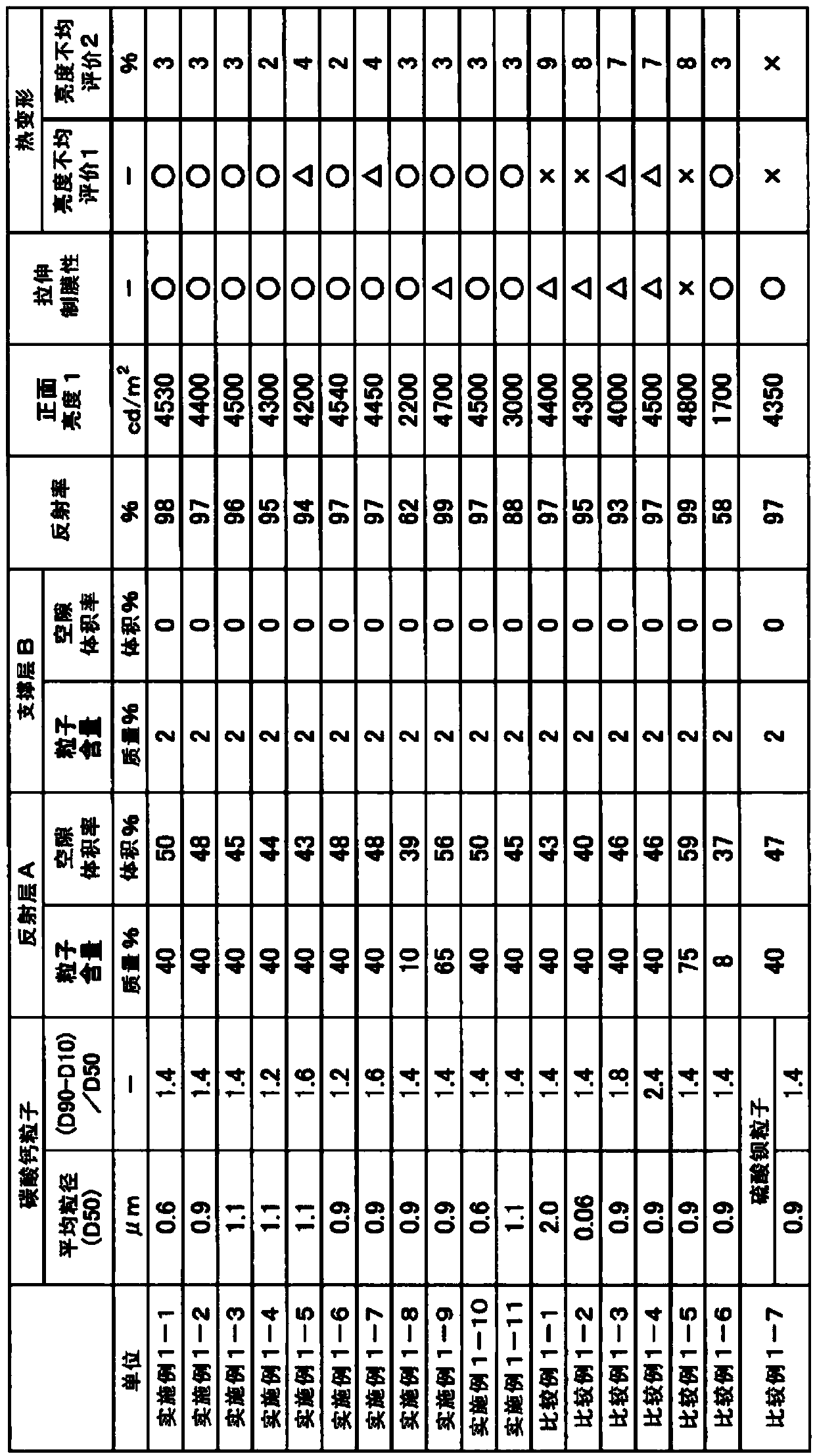

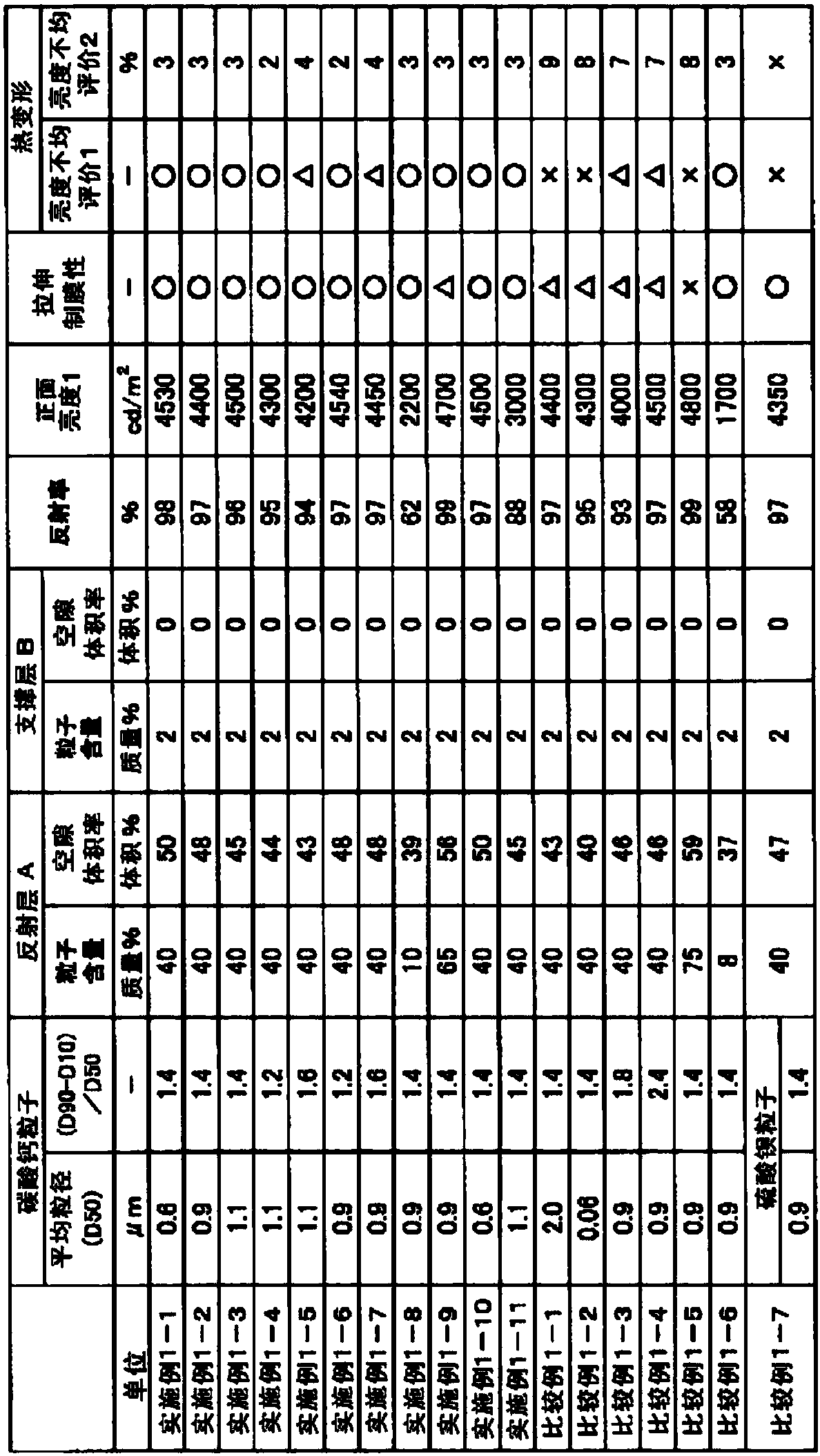

[0168] The present invention is described in detail below through examples. In addition, each characteristic value was measured by the following method.

[0169] (1) Light reflectivity

[0170] An integrating sphere was installed on a spectrophotometer (UV-3101PC manufactured by Shimadzu Corporation), and the concentration of BaSO was measured at a wavelength of 550 nm. 4 The reflectance when the whiteboard was set at 100%, was taken as the reflectance. In addition, the measurement was performed on the side used as the reflective surface, that is, the surface on the light source side.

[0171] (2) The average particle size of the particles

[0172] Measurement was performed using a laser scattering particle size distribution analyzer SALD-7000 manufactured by Shimadzu Corporation. For dispersion in ethylene glycol before measurement, the particle powder was weighed to correspond to a slurry concentration of 5% by mass, stirred in a mixer for 10 minutes, cooled to normal te...

manufacture example 1

[0212]

[0213] 136.5 parts by mass of dimethyl terephthalate, 13.5 parts by mass of dimethyl isophthalate (that is, the isophthalic acid component is 9 mol% relative to 100 mol% of the total acid components of the obtained polyester), ethylene glycol Add 98 parts by mass of alcohol, 1.0 part by mass of diethylene glycol, 0.05 part by mass of manganese acetate, and 0.012 parts by mass of lithium acetate into a flask equipped with a rectification tower and a distillation condenser, and heat to 150-240° C. while stirring, Methanol was distilled off for transesterification. After methanol was distilled off, 0.03 parts by mass of trimethyl phosphate and 0.04 parts by mass of germanium dioxide were added, and the reactant was moved to a reactor. Then, while stirring, the pressure in the reactor was gradually reduced to 0.3 mmHg, and at the same time, the temperature was raised to 292° C. to carry out polycondensation reaction to obtain isophthalic acid copolymerized polyethylene ...

manufacture example 2

[0214]

[0215] Except changing to 129.0 parts by mass of dimethyl terephthalate and 21.0 parts by mass of dimethyl isophthalate (that is, the isophthalic acid component is 14 mol% relative to 100 mol% of the total acid components of the obtained polyester), Otherwise, isophthalic acid-copolymerized polyethylene terephthalate 2 was obtained in the same manner as in Production Example 1 above. The polymer has a melting point of 215°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com