Iron-based nanocrystalline alloy ultra-thin broadband and its manufacturing method

An iron-based nanocrystalline, ultra-thin technology, used in magnetic objects, magnetic materials, electrical components, etc., can solve problems such as many impurities, nozzle deformation, and increased spray pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

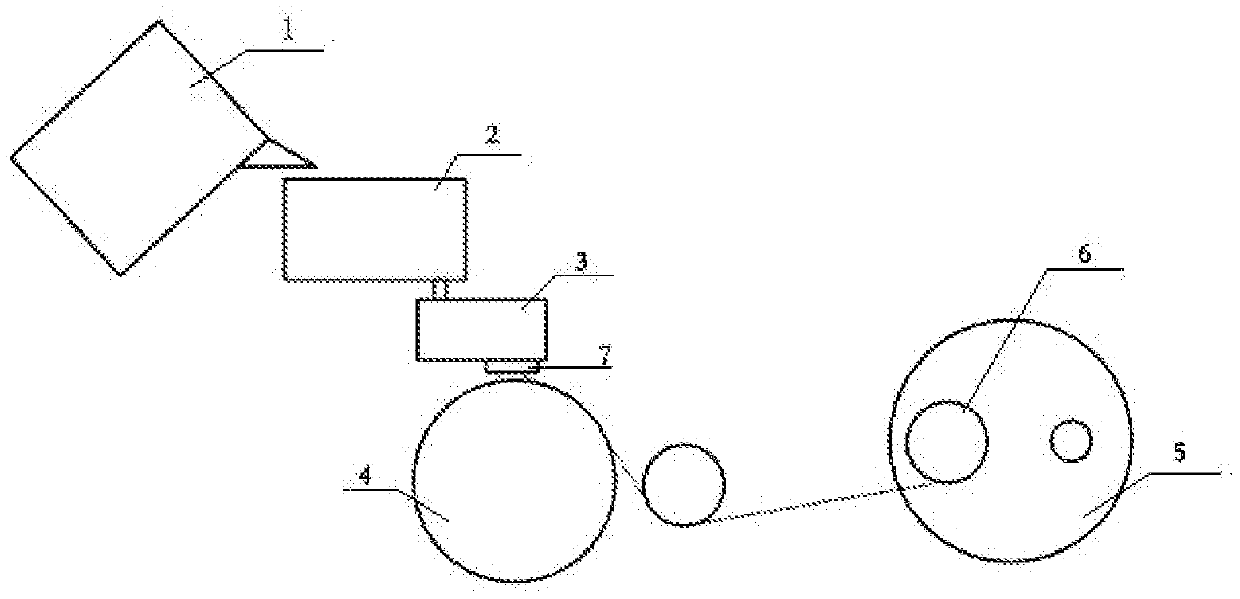

[0119] Within the scope of the chemical composition of the iron-based amorphous alloy described in the present invention, 6 different iron-based amorphous alloy components are selected respectively, and the serial numbers are 1-6, and the nanocrystalline alloy broadband is manufactured by the planar flow casting process, and the main process parameters as follows:

[0120] (1) Use pure iron, ferroboron, ferrosilicon, ferroniobium, ferrophosphorus, copper ingot, aluminum ingot, and tin ingot as raw materials for master alloy smelting, and prepare raw materials according to the expressions of each alloy in Table 1, under the protection of argon The raw materials are melted and superheated in induction furnace or other smelting furnace 1 to form molten steel with uniform composition. The smelting temperature is 1400°C, and the smelting time is 30 minutes. After the molten steel is cleared, it is overheated at 1550°C, and the overheating time is 20 minutes, to obtain uniform molte...

Embodiment 2

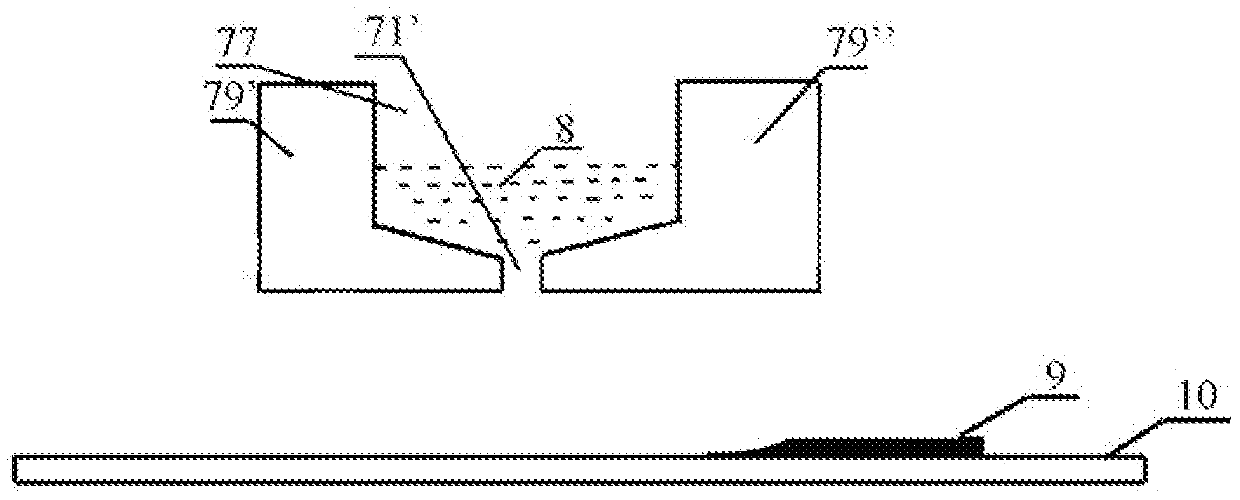

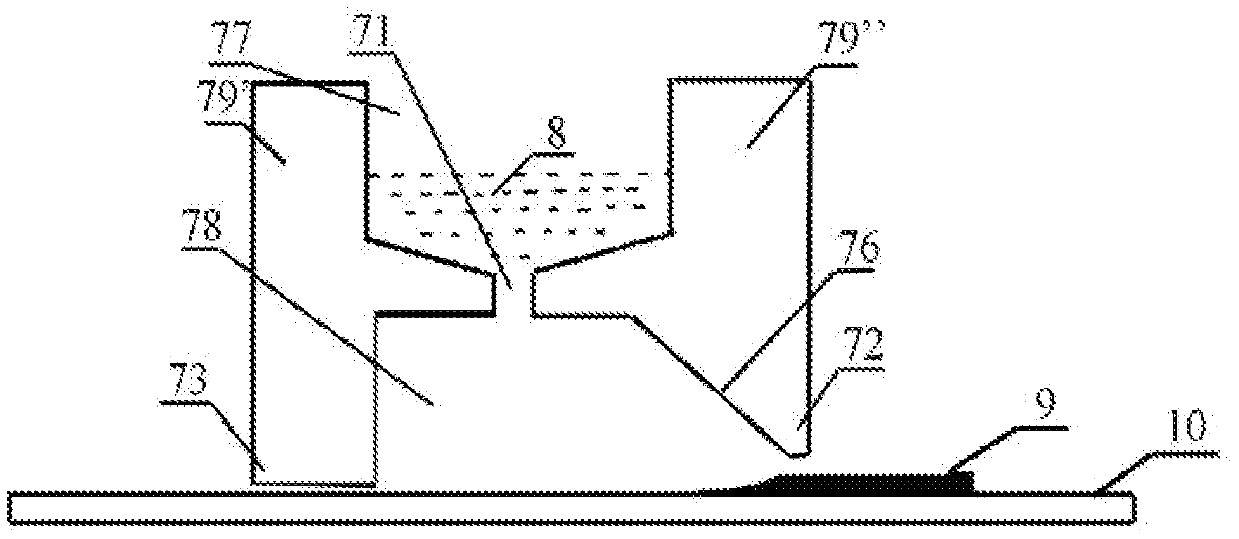

[0130] The addition of trace surface active elements Al and Sn in the present invention can greatly reduce the surface tension of the melt during spraying without reducing the viscosity of the melt, and adjust the shape and shape of the molten pool by coordinating the interaction between the surface tension and viscosity of the melt. Size to improve the stability of the molten pool, so as to achieve the purpose of improving the flatness of the free surface of the strip, and reduce the difficulty of unpacking, greatly improving the process of strip production and product quality stability. Within the scope of the chemical composition of the iron-based amorphous alloy of the present invention, select 6 different iron-based amorphous alloy components respectively, and the serial numbers are 7-12 (wherein the alloys of serial numbers 7 and 11 are comparative examples), and use a plane Flow casting process to manufacture nanocrystalline alloy broadband, the main process parameters a...

Embodiment 3

[0140] The invention adopts the nozzle spray belt embedded in the molten pool, which greatly improves the stability of the molten pool and the surface quality of the free surface of the strip. The precision on-line grinding device can improve the surface quality of the roll surface of the strip, and the three parameters are coordinated with each other to further improve the quality of the ultra-thin broadband. Within the chemical composition range of the iron-based amorphous alloy described in the present invention, 6 different iron-based amorphous alloy components are selected respectively, and the serial numbers are 13-18, and the nanocrystalline alloy broadband is manufactured by the planar flow casting process, and the main process parameters as follows:

[0141] (1) Use pure iron, ferroboron, ferrosilicon, ferroniobium, ferrophosphorus, copper ingot, aluminum ingot, and tin ingot as raw materials for master alloy smelting, and prepare raw materials according to the expres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com