A supported sulfide ionic liquid-promoted ruthenium catalyst and its application in the hydrohalogenation of unsaturated hydrocarbons

An ionic liquid, ruthenium catalyst technology, applied in physical/chemical process catalysts, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as sublimation loss, improve reaction activity, and enhance stability. , the effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

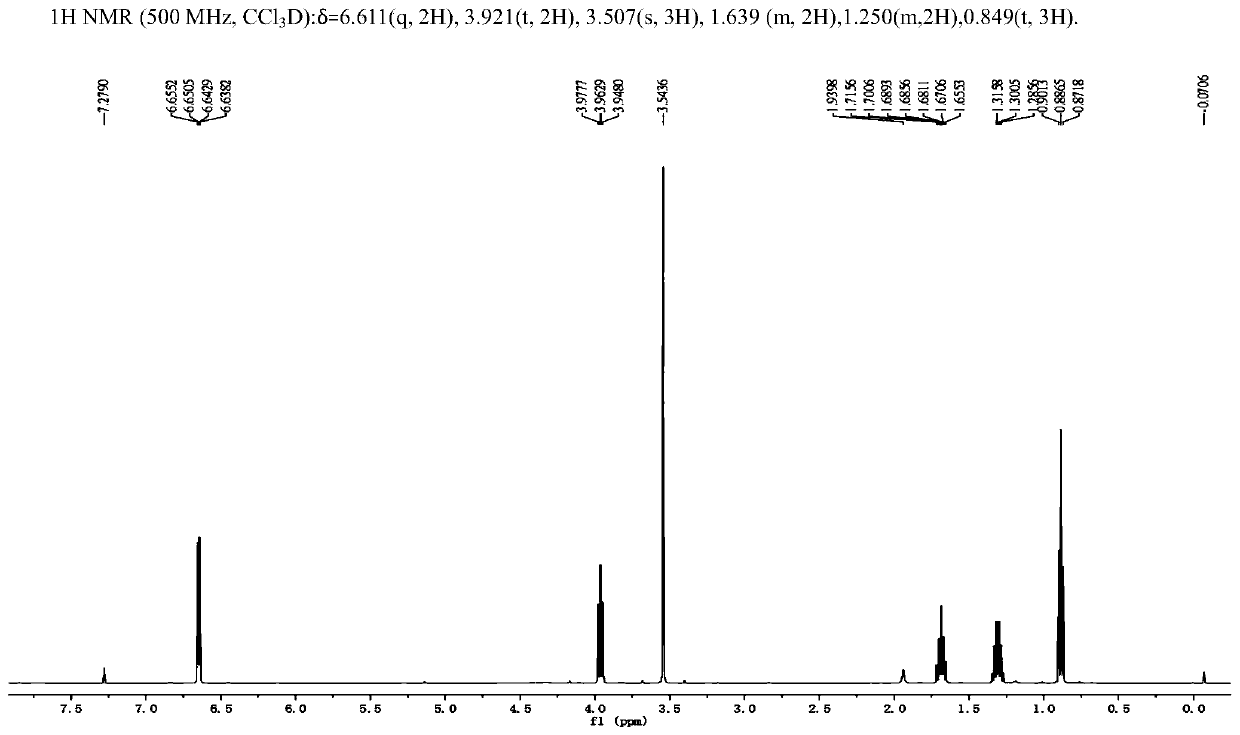

[0059] Synthesis of sulfide ionic liquid A:

[0060] Mix ionic liquid mono-butyl-tri-methylimidazolium chloride and sulfur powder according to the mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C for 12 hours, Stir the above mixture evenly, then filter to remove unreacted sulfur powder, dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying in dichloromethane, add an appropriate amount of Ionized water and sodium bicarbonate solution were used to further remove impurities in the solution. Finally, the above mixed solution was dried at 110° C. for 16 hours, and then recrystallized at room temperature to obtain the desired sulfide ionic liquid A.

[0061] Select columnar activated carbon as the carrier, its particle size is 40 mesh, the ash content is 3.0wt%, and the specific surface area is 950m 2 / g, pore volume 0.6ml / g. 50ml of RuCl 3 After mixing the solution (in which ...

Embodiment 2

[0064] Synthesis of sulfide ionic liquid A:

[0065] Mix ionic liquid mono-butyl-tri-methylimidazolium chloride and sulfur powder according to the mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C for 12 hours, Stir the above mixture evenly, then filter to remove unreacted sulfur powder, dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying in dichloromethane, add an appropriate amount of Ionized water and sodium bicarbonate solution were used to further remove impurities in the solution. Finally, the above mixed solution was dried at 110° C. for 16 hours, and then recrystallized at room temperature to obtain the desired sulfide ionic liquid A.

[0066] Select columnar activated carbon as the carrier, its particle size is 40 mesh, the ash content is 3.0wt%, and the specific surface area is 950m 2 / g, pore volume 0.6ml / g. 10ml of RuCl 3 After the solution (the Ru content i...

Embodiment 3

[0069] Synthesis of sulfide ionic liquid A:

[0070] Mix ionic liquid mono-butyl-tri-methylimidazolium chloride and sulfur powder according to the mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C for 12 hours, Stir the above mixture evenly, then filter to remove unreacted sulfur powder, dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying in dichloromethane, add an appropriate amount of Ionized water and sodium bicarbonate solution were used to further remove impurities in the solution. Finally, the above mixed solution was dried at 110° C. for 16 hours, and then recrystallized at room temperature to obtain the desired sulfide ionic liquid A.

[0071] Select columnar activated carbon as the carrier, its particle size is 40 mesh, the ash content is 3.0wt%, and the specific surface area is 950m 2 / g, pore volume 0.6ml / g. 5ml of RuCl 3 After the solution (the Ru content is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com