Weather-resistant urea formaldehyde resin preparation method

A urea-formaldehyde resin and weather resistance technology, applied in the field of weather-resistant urea-formaldehyde resin and its preparation, can solve the problems of lack of in-depth research on thermal stability, poor weather resistance and heat resistance, and poor dimensional stability, and improve application performance. and expansion, good weather resistance, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

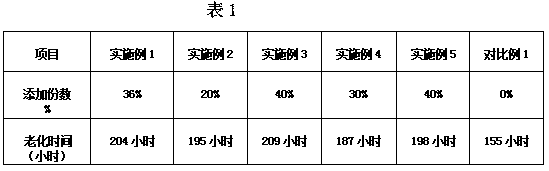

Examples

Embodiment 1

[0040] A weather-resistant urea-formaldehyde resin prepared by the following method:

[0041] (1) Synthesis steps of acrylate solution:

[0042] Synthesis of acrylate solution: Add 150ml of deionized water, 1.0g, and emulsifier sodium lauryl sulfate in a 500ml round bottom three-neck flask with stirring, turn on the stirring, and then add 23g methyl methacrylate to the flask Control the temperature to 55-60℃, add 0.3g potassium persulfate, and add 77g butyl acrylate dropwise so that the reaction temperature does not exceed 80℃. After the reaction is completed, keep the temperature for 0.5-1.0 hours, cool to room temperature, and filter to obtain acrylic acid Ester solution.

[0043] (2) Preparation steps of urea-formaldehyde resin:

[0044] ①Synthesis of urea-formaldehyde resin prepolymer: add 22.0g of urea, 33.0mL of formaldehyde and 250.0mL of deionized water into a three-necked flask, use sodium carbonate to increase the pH of the solution to 8, and increase the temperature to 75℃...

Embodiment 2

[0050] A weather-resistant urea-formaldehyde resin prepared by the following method:

[0051] (1) Synthesis steps of acrylate solution:

[0052] Synthesis of acrylate solution: Add 150ml of deionized water, 1.0g, and the emulsifier sodium lauryl sulfate into a 500ml round bottom three-necked flask with stirring, turn on the stirring, then add 21g methyl methacrylate to the flask Control the temperature to 55-60℃, add 0.3g ammonium persulfate, and add 79g butyl acrylate dropwise so that the reaction temperature does not exceed 80℃. After the reaction is completed, keep the temperature for 0.5-1.0 hours, cool to room temperature, and filter to obtain acrylic acid Ester emulsion.

[0053] (2) Preparation steps of urea-formaldehyde resin:

[0054] ①Synthesis of urea-formaldehyde resin prepolymer: Put 40.0g of urea, 40.0mL of formaldehyde and 250.0mL of deionized water into a three-necked flask, increase the pH of the solution to 9 with sodium carbonate, and increase the temperature to 75...

Embodiment 3

[0058] A weather-resistant urea-formaldehyde resin prepared by the following method:

[0059] (1) Synthesis steps of acrylate solution:

[0060] Synthesis of acrylate solution: Add 150ml deionized water, 1.1g, and emulsifier sodium lauryl sulfate in a 500ml round bottom three-neck flask with stirring, then turn on the stirring, and then add 33g methyl methacrylate to the flask Control the temperature to 55-60℃, add 0.4g potassium persulfate, and add 67g butyl methacrylate dropwise so that the reaction temperature does not exceed 80℃. After the reaction is completed, keep it for 0.5-1.0 hours, cool to room temperature, and filter. , Acrylic emulsion is obtained.

[0061] (2) Preparation steps of urea-formaldehyde resin

[0062] ①Synthesis of urea-formaldehyde resin prepolymer: Put 50.0g of urea, 50.0mL of formaldehyde and 250.0mL of deionized water into a three-necked flask, increase the pH of the solution to 12 with sodium carbonate, and increase the temperature to 75℃, continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com