Silicone rubber reinforced and cross-linked based on POSS, and preparation method thereof

A silicone rubber and reinforcement technology, which is applied in the field of POSS crosslinked and reinforced silicone rubber and its preparation, can solve problems such as weak force, and achieve the effect of strong practicability, simple and efficient synthesis method, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Base glue α,ω-aminopropyl polydimethylsiloxane (viscosity about 30000mPa.s) 100g, cyclocarbonate modified POSS 3g, mix well at room temperature (20℃~25℃), place in the mold , 60 ℃ vulcanization 6h to get silicone rubber;

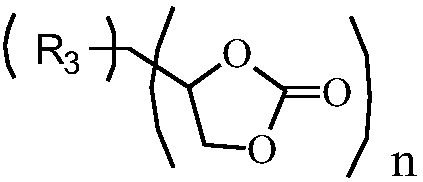

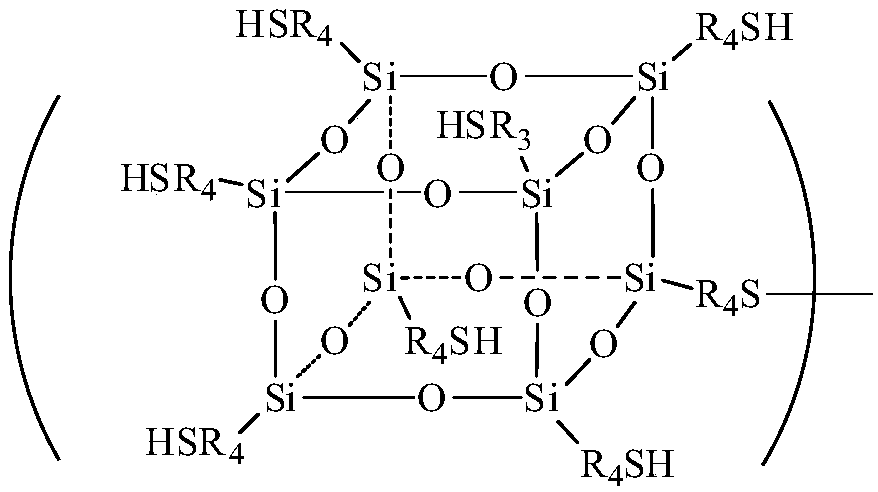

[0056] Wherein, the structural formula of cyclocarbonate modified POSS is:

[0057]

[0058] where n=6,

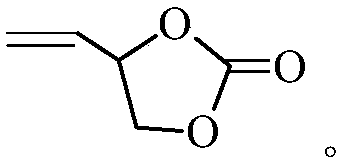

[0059] Preferably, the R 3 The structural formula is:

[0060]

[0061] Among them, R 4 for -CH 2 -CH 2 -CH 2 -.

[0062] According to the national standard GB / T531.1-2008, GB / T528-2009, GB / T529-2008 respectively measure the hardness, tensile strength and elongation at break of the vulcanized silicone rubber.

[0063] The hardness is 40Shore A, the tensile strength is 5.6MPa, the elongation at break is 467%, and the tear strength is 13.6kN / m.

Embodiment 2

[0065] Repeat the steps described in Example 1, except that the viscosity of the base glue α, ω-aminopropyl polydimethylsiloxane is 5000 mPa.s.

[0066] The hardness is 45Shore A, the tensile strength is 4.5MPa, the elongation at break is 412%, and the tear strength is 12.3kN / m.

Embodiment 3

[0068] Repeat the steps described in Example 1, except that the base glue α, ω-aminopropyl polydimethylsiloxane has a viscosity of 50000 mPa.s.

[0069] The hardness is 38Shore A, the tensile strength is 7.1MPa, the elongation at break is 532%, and the tear strength is 15.0kN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com