Paper deacidification system with rotation bracket and deacidification method

A deacidification and paper technology, which is applied in the post-processing of waste paper, post-processing of printing, printing and other directions, can solve the problems of affecting the appearance and structural stability of paper cultural relics, secondary destruction of ancient books and documents, and difficulty in batch processing. Achieve the effect of improving batch processing efficiency, accelerating diffusion, and convenient use and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

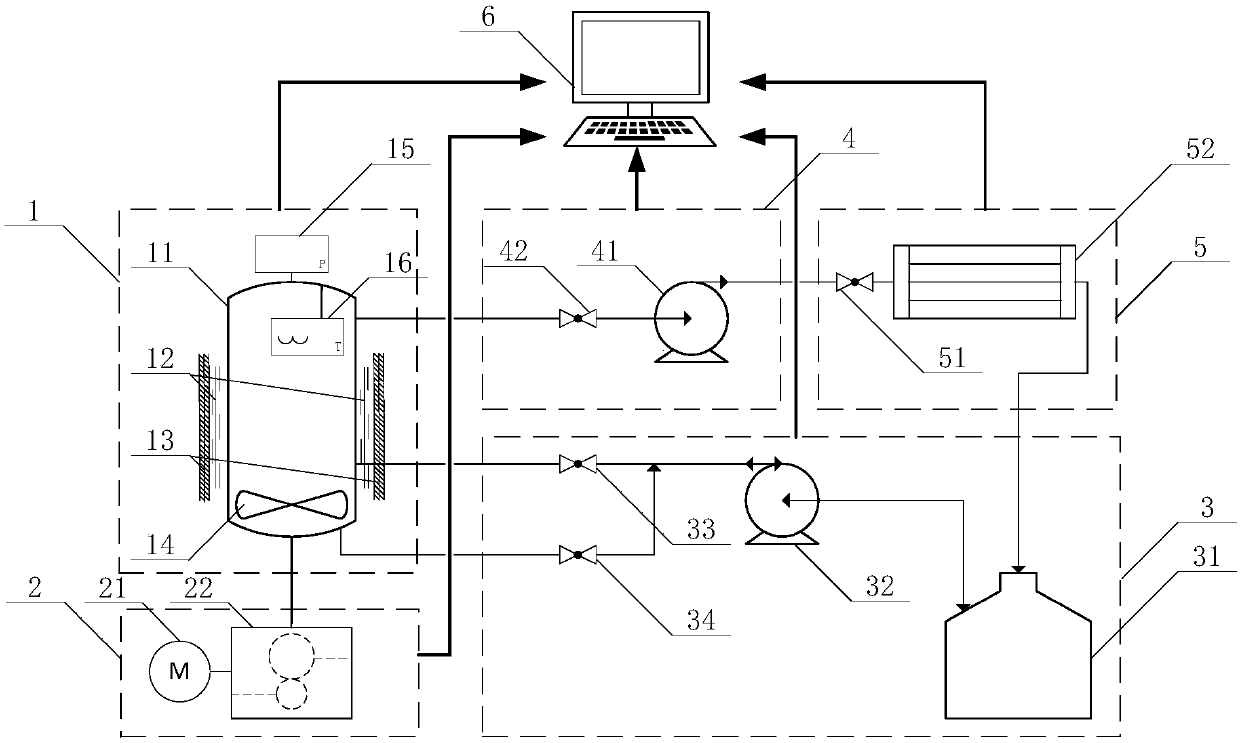

[0038] A paper deacidification system with a rotating carriage such as figure 1 As shown, it includes a deacidification reactor 1, a drive system 2, a deacidification liquid injection and return system 3, a vacuum system 4, a deacidification liquid recovery device 5 and an intelligent operation console 6.

[0039]The outlet of the deacidification liquid storage tank 31 is connected with the deacidification liquid inlet of the deacidification tank 11 through the centrifugal pump 32 and the inlet valve 33, and the deacidification liquid outlet of the deacidification tank 11 is connected with the deacidification liquid storage tank through the outlet valve 34 and the centrifugal pump 32. The outlet of the tank 31 is connected, the outlet of the deacidification barrel 11 is connected with the inlet of the condenser 52 through the first vacuum ball valve 42, the vacuum pump 41 and the second vacuum ball valve 51, and the outlet of the condenser 52 is connected with the inlet of the ...

Embodiment 2

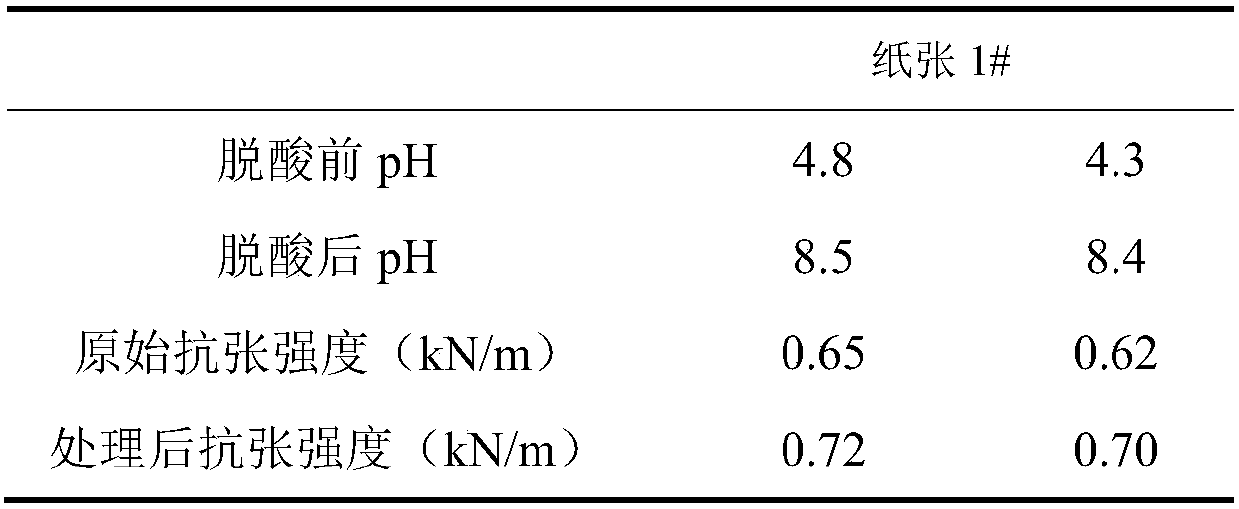

[0055] Get a number of books during the period of the Republic of China with a pH value of about 4.5, and adopt the method for paper deacidification in Example 1,

[0056] In the step (1), the deacidification solution is Mg(OH) with a pH value of 12.8 2 perfluorohexane suspension, and a small amount of paper-strengthening agent-modified starch in the deacidification solution.

[0057] Pre-evacuate to 10Pa in step (1).

[0058] In step (2), the rotational speed of the motor is controlled at 30 rpm by the transmission, the forward and reverse directions rotate alternately, the exchange frequency is 1 min, and the deacidification reaction time is 40 min.

[0059] In step (4), the heating temperature is 60° C., and the drying is performed for 120 minutes.

[0060] Take 2g of acidified paper and paper after deacidification treatment and soak them in a beaker filled with 100mL distilled water (pH=6.3), shake once in the middle, take out the paper after 1 hour, and measure the pH v...

Embodiment 3

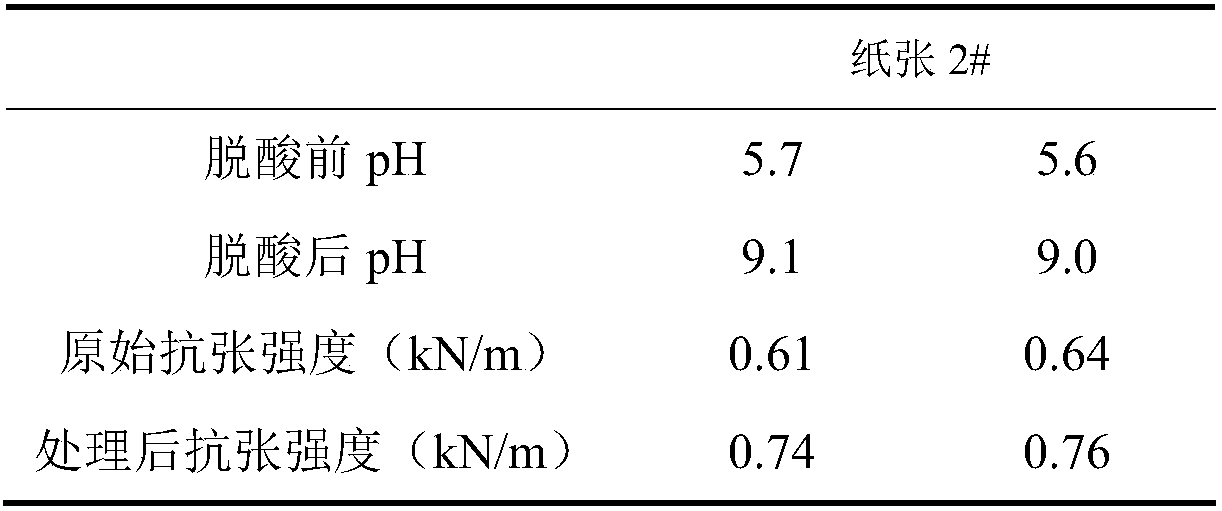

[0064] Get a number of books during the period of the Republic of China with a pH value of about 5.7, and adopt the method for paper deacidification in Example 1,

[0065] In the step (1), the deacidification solution is Mg with a pH value of 12.1 4 Al-LDHs (structural formula is [Mg 8 Al 2 (OH) 20 ](CO 3 )·4H 2 O) trichlorotrifluoroethane suspension, containing a small amount of paper reinforcing agent modified cellulose in the deacidification solution simultaneously.

[0066] Pre-evacuate to 60Pa in step (1).

[0067] In step (2), the rotational speed of the motor is controlled at 45 rpm by the transmission, and the forward and reverse directions rotate alternately, the exchange frequency is 3 minutes, and the deacidification reaction time is 30 minutes.

[0068] In step (4), vacuumize and dry at room temperature.

[0069] Take 2g of acidified paper and paper after deacidification treatment and soak them in a beaker filled with 100mL distilled water (pH=6.3), shake on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com