Fluorine-containing lithium ion battery positive electrode material and preparation method thereof

A technology of lithium ion battery and positive electrode material, applied in the field of positive electrode material of fluorine-containing lithium ion battery and its preparation, can solve the problems of high residual alkali content on the surface of high nickel positive electrode material, poor processing performance and electrochemical performance, etc. Low, unique raw materials, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a method for preparing a positive electrode material for a fluorine-containing lithium ion battery, the specific preparation method of which is:

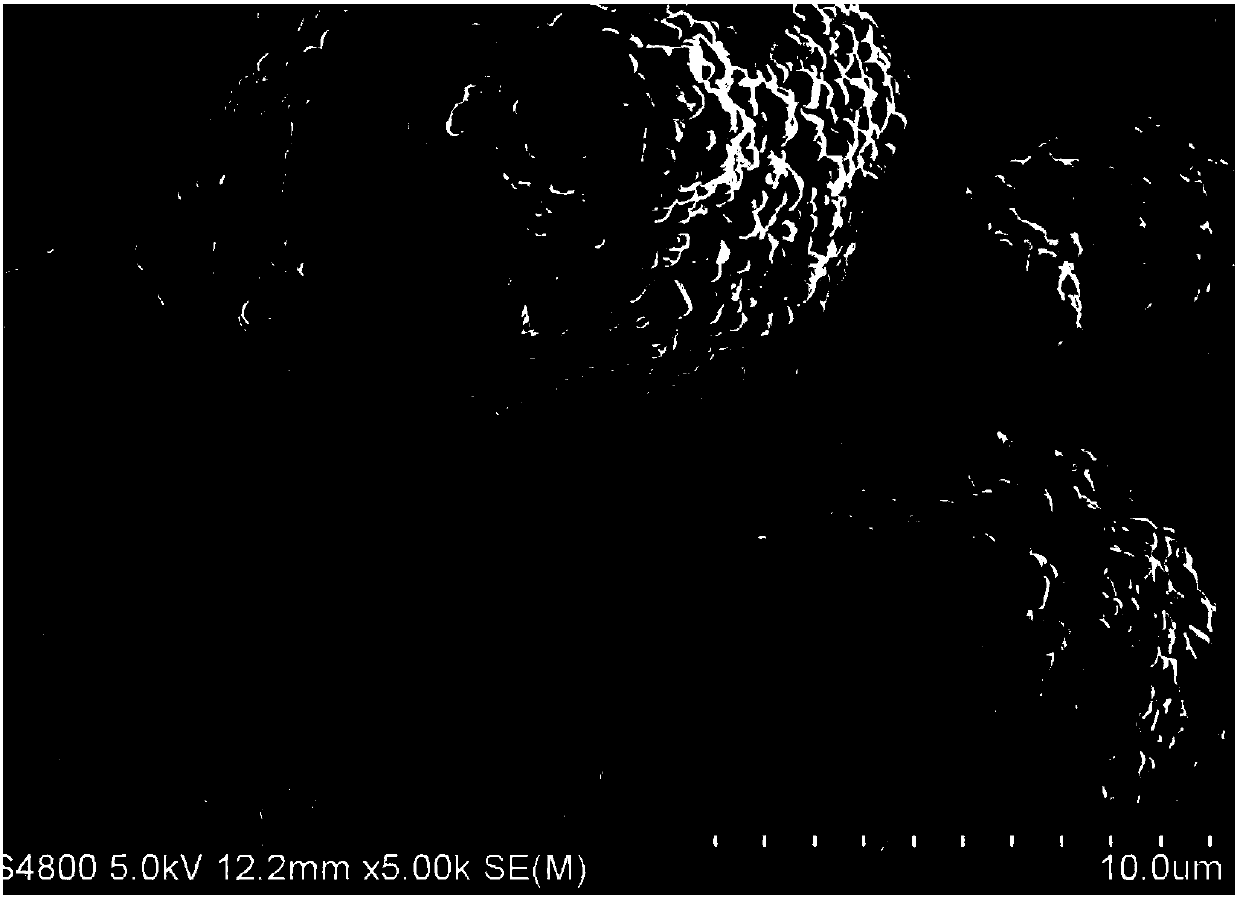

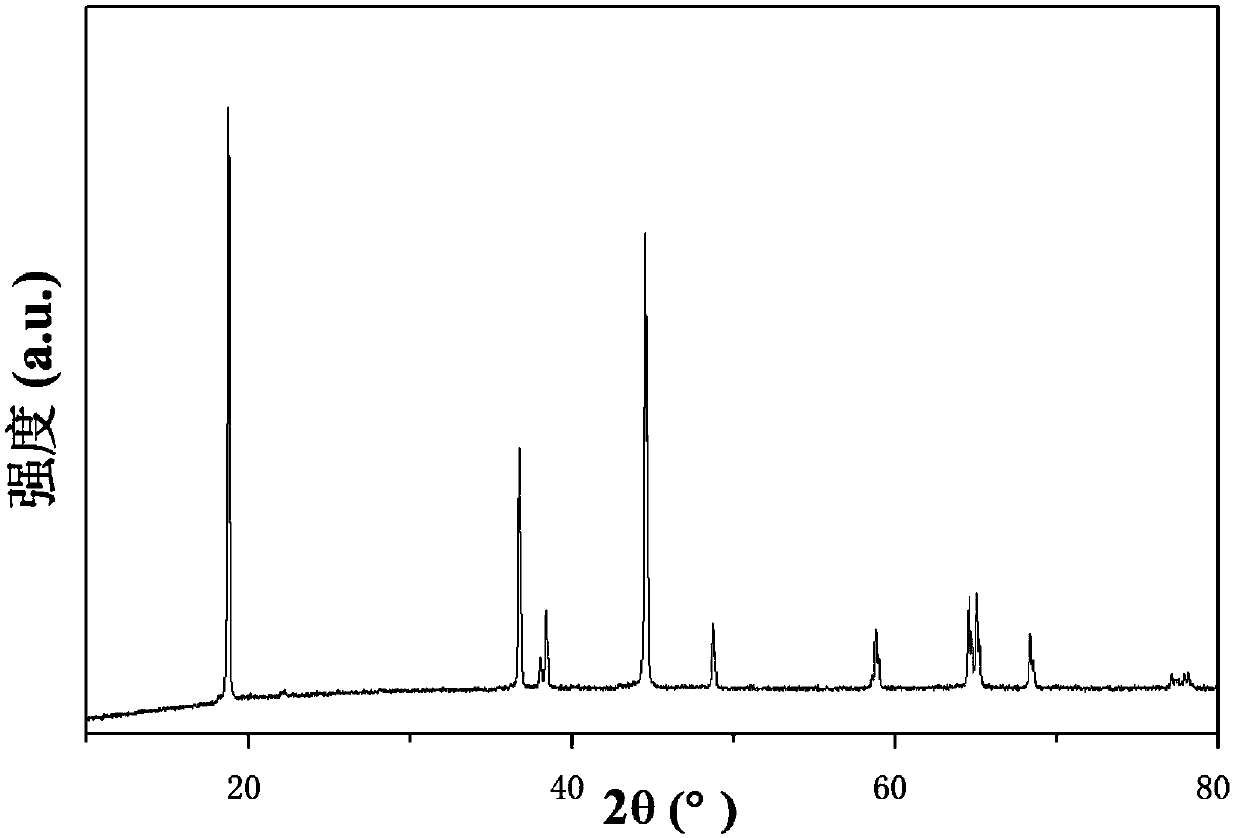

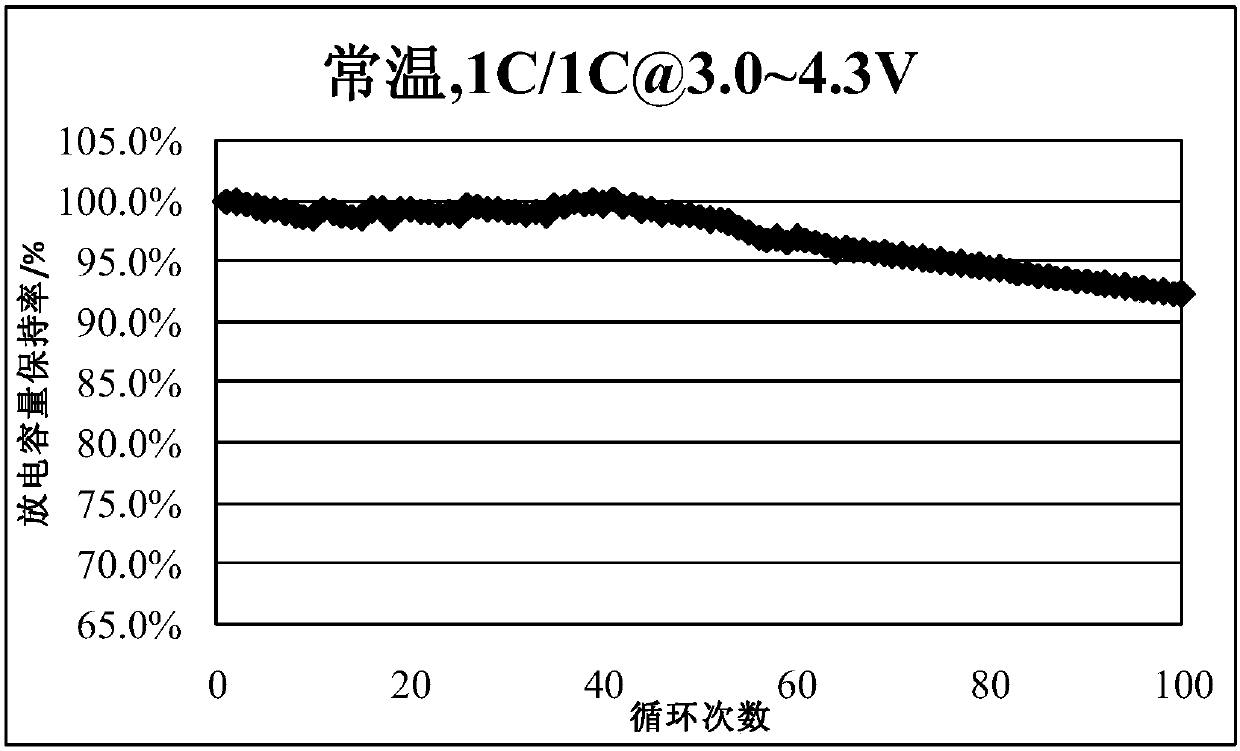

[0058] First, 1g of ammonium fluorosilicate was dissolved in water and added to the reaction kettle, and the high-nickel cathode material LiNi with an average particle size of 12.5 μm was weighed. 0.815 co 0.15 al 0.035 o 2 Slowly add 100g into the reaction kettle, the solid-to-liquid mass ratio of the high-nickel cathode material to the salt solution containing polyfluorinated compounds is 2:1, the stirring speed is 300r / min, after 30min of reaction, turn on the heating source, and the heating temperature is 100°C , drying while stirring, the stirring speed is 500rpm, the drying time is 60min, the dried LiNi 0.815 co 0.15 al 0.035 o 2 Place in a box-type atmosphere furnace, sinter under nitrogen atmosphere, heat treatment temperature is 400 °C, holding time 6h, and cool to room temperature wit...

Embodiment 2

[0067] This embodiment provides a method for preparing a positive electrode material for a fluorine-containing lithium ion battery, the specific preparation method of which is:

[0068] First, 2 g of ammonium fluorozirconate was dissolved in water and added to the reaction kettle, and the high-nickel cathode material LiNi with an average particle size of 12.0 μm was weighed. 0.80 co 0.10 mn 0.10 o 2 100g was slowly added to the reaction kettle, the solid-to-liquid mass ratio of the high-nickel positive electrode material to the salt solution containing polyfluorinated compounds was 1:1, the stirring speed was 300r / min, and after 30min of reaction, the heating source was turned on, and the heating temperature was 110°C. Stir while drying, the stirring speed is 600rpm, the drying time is 80min, the dried LiNi 0.80 co 0.10 mn 0.10 o 2 Place in a box-type atmosphere furnace, sinter under nitrogen atmosphere, heat treatment temperature is 400 °C, holding time 6h, and cool to...

Embodiment 3

[0073] This embodiment provides a method for preparing a positive electrode material for a fluorine-containing lithium ion battery, the specific preparation method of which is:

[0074] First, 5 g of magnesium trifluoromethanesulfonate was dissolved in water and added to the reaction kettle, and the high-nickel cathode material LiNi with an average particle size of 11.5 μm was weighed. 0.83 co 0.10 mn 0.07 o 2 Slowly add 100g into the reaction kettle, the solid-to-liquid mass ratio of the high-nickel cathode material to the salt solution containing polyfluorinated compounds is 1:2, the stirring speed is 400r / min, after 30 minutes of reaction, turn on the heating source, and the heating temperature is 110°C , drying while stirring, the rotating speed is 500rpm, the drying time is 100min, the dried LiNi 0.83 co 0.10 mn 0.07 o 2 Place in a box-type atmosphere furnace, sinter under nitrogen atmosphere, heat treatment temperature is 350 °C, holding time 8h, and cool to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com