Titanium-doped lithium-enriched manganese-based lithium ionic battery cathode material and preparation method thereof

A lithium-rich manganese-based lithium and cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of low specific capacity and short cycle life of materials, and achieve improved comprehensive performance and short preparation cycle. , the effect of improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

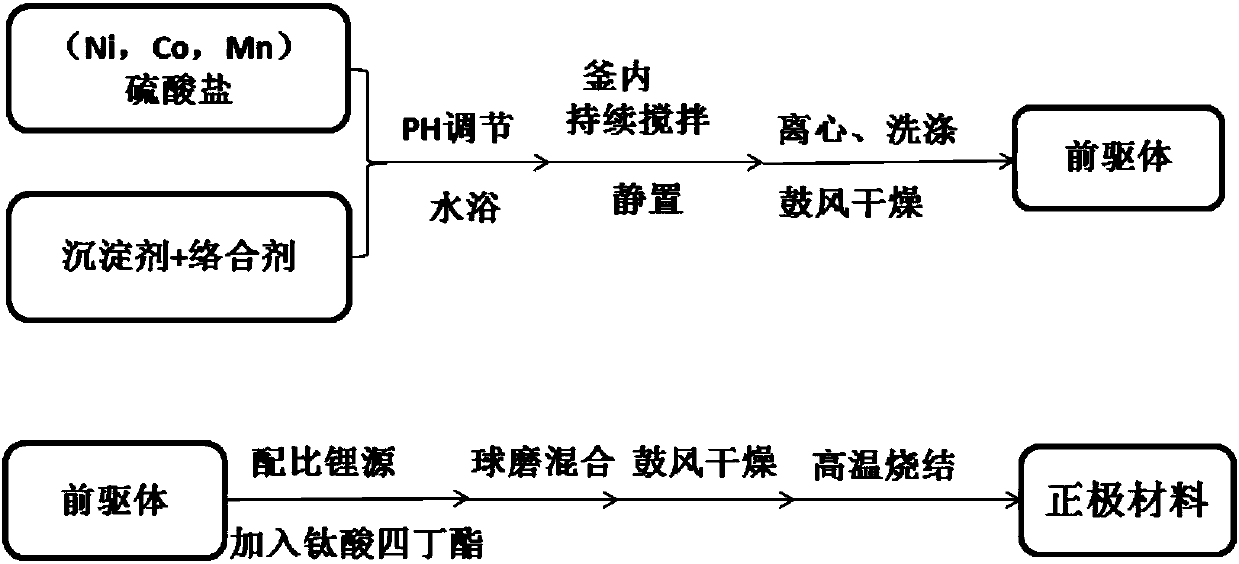

[0037] (1) Co-precipitation steps to prepare nickel-cobalt-manganese carbonate precursor:

[0038] Such as figure 1 , Nickel sulfate, cobalt sulfate, manganese sulfate are formulated into the uniform solution that metal ion concentration is 1mol / L according to the metal ion ratio Ni:Co:Mn=1:1:4 of prepared material, and described metal ion refers to Ni, The sum of Co and Mn ions. Weigh a sufficient amount of sodium carbonate to prepare a 2mol / L solution as a precipitant, and add saturated ammonia to the sodium carbonate solution to prepare a 0.3mol / L ammonia complexing agent. The ratio of nickel-cobalt-manganese metal ions in the bottom liquid of the reactor is the same as that of the feed liquid, and the concentration of metal ions in the bottom liquid is 0.167mol / L. Add ammonia complexing agent into the reactor until the bottom liquid environment in the reactor reaches pH =8.0, adjust the temperature in the kettle to 50°C, and the stirring speed to 500rpm, continuously add...

Embodiment 2

[0045] (1) Co-precipitation steps to prepare nickel-cobalt-manganese carbonate precursor:

[0046] Nickel acetate, cobalt acetate, and manganese acetate are formulated into a uniform solution with a metal ion concentration of 1mol / L according to the metal ion ratio of the prepared material Ni:Co:Mn=1:1:4, and a sufficient amount of sodium carbonate is weighed to prepare 2mol / L solution is used as a precipitant, and NaOH solution is added to the sodium carbonate solution to form a 0.3mol / L complex precipitant. The ratio of nickel-cobalt-manganese metal ions in the bottom liquid of the reactor is the same as that of the feed liquid, and the concentration of metal ions in the bottom liquid is 0.167mol / L. Add a complexing precipitation agent into the reactor to make the environment of the bottom liquid in the reactor reach the pH =8.0, when the temperature in the kettle was 50°C, and the stirring speed was 500 rpm, the salt solution was continuously added into the reaction kettle...

Embodiment 3

[0053] (1) Co-precipitation steps to prepare nickel-cobalt-manganese carbonate precursor:

[0054] Such as figure 1 , nickel nitrate, cobalt nitrate, manganese nitrate are formulated into a uniform solution with a metal ion concentration of 1mol / L according to the metal ion ratio Ni:Co:Mn=1:1:4 of the prepared material, and a sufficient amount of sodium carbonate is weighed to prepare 2mol / L solution is used as a precipitating agent, and KOH solution is added to the sodium carbonate solution to form a 0.3mol / L complex precipitating agent. The proportion of nickel-cobalt-manganese metal ions in the bottom liquid of the reactor is the same as that of the feed liquid, and the concentration of metal ions in the bottom liquid is 0.167mol / L. Add a complexing precipitant into the reactor until the bottom liquid environment in the reactor reaches pH =8.5, when the temperature in the kettle was 50°C, and the stirring speed was 500 rpm, the salt solution was continuously added into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com