Alkaline residue treatment method

A treatment method and technology for alkali residues, applied in the field of industrial waste treatment, can solve the problems of poor microbial colony adaptability and treatment effect, not yet achieved good treatment effect, insufficient equipment load bearing capacity, etc., so as to achieve no secondary pollution, Good social benefits and effects of important environmental protection significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

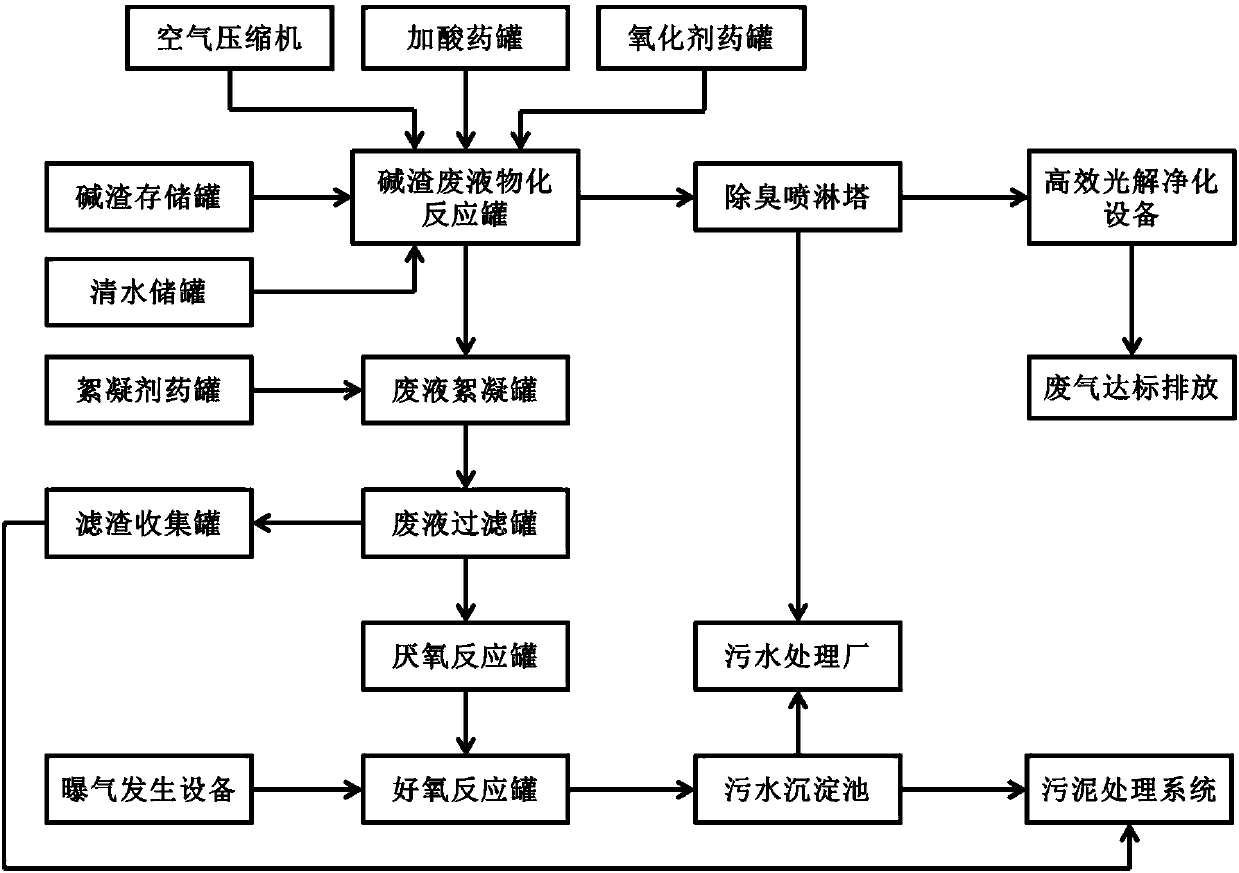

Image

Examples

Embodiment Construction

[0028] In order to make it easier for those skilled in the art to understand the technical solution of this patent, and at the same time, in order to make the technical purpose, technical solution and beneficial effect of this patent clearer, and to fully support the protection scope of the claims, the following is a specific case in the form of this patent. The technical solution of the patent makes further and more detailed descriptions.

[0029] A kind of alkali slag processing method, it comprises the following steps:

[0030] (1) According to the pH value of the alkali slag to be treated, the COD value and the total input amount of the alkali slag to be treated in the physical and chemical reaction tank, add sufficient water in advance in the physical and chemical reaction tank, so that the alkali slag of the total input amount is dissolved in The COD value of sufficient water is less than 50,000 mg / L;

[0031] (2) Open the microbubble generator on the physical and chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com