Homogeneous metal organic framework material as well as preparation method and application thereof

A metal-organic framework and organic ligand technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high production cost and application prospects to be observed, and achieve low cost, low reuse cost, and low isothermal adsorption. The effect of enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a preparation method of N,N'-bis(3,5-dicarboxybenzene)-1,4,5,8-naphthalimide organic ligand, which specifically includes the following steps:

[0032] 1.81g of 5-amino-isophthalic acid and 1.34g of 1,4,5,8-naphthalenetetracarboxylic anhydride were added to 25mL of glacial acetic acid solution, reacted at 120°C for 15 hours, and after cooling to room temperature, Filter, collect the precipitate, wash with distilled water until the pH of the washing liquid is neutral, and dry at 80°C under vacuum for 12 hours to obtain N,N'-bis(3,5-dicarboxybenzene)-1,4,5, 8-naphthalimide organic ligand 2.4g, the yield is 77%.

Embodiment 2

[0034] This embodiment relates to a method for preparing a homogeneous Cu-organic framework, which specifically includes the following steps:

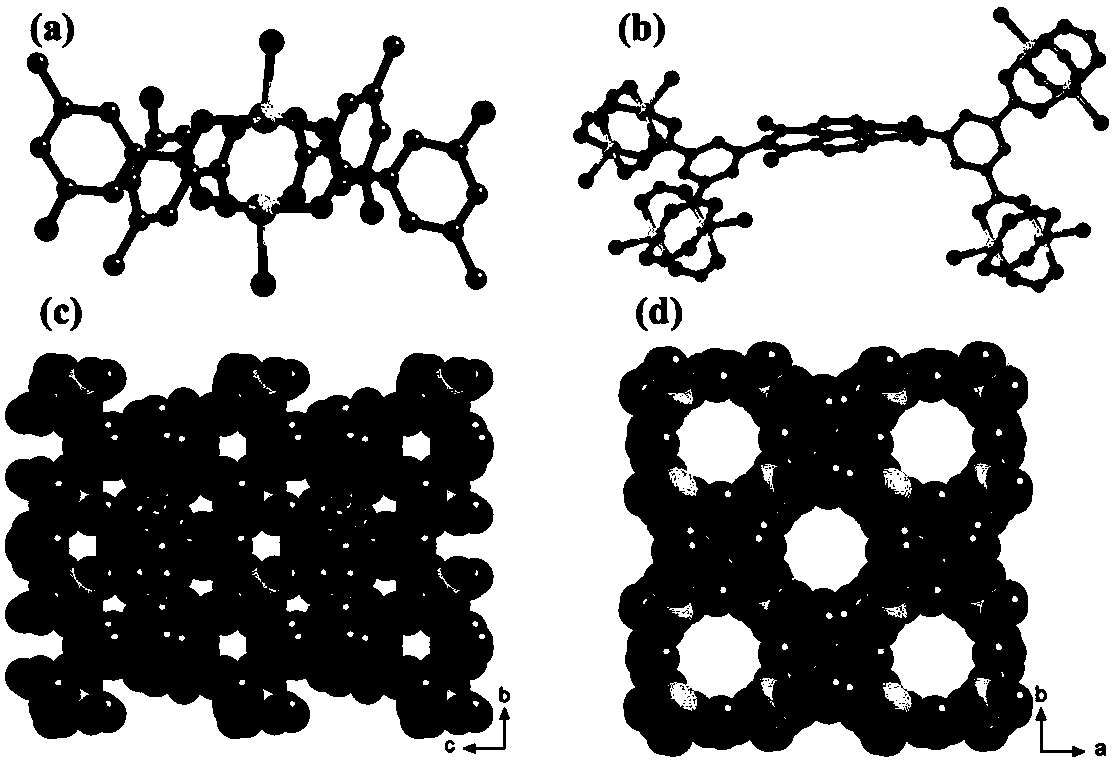

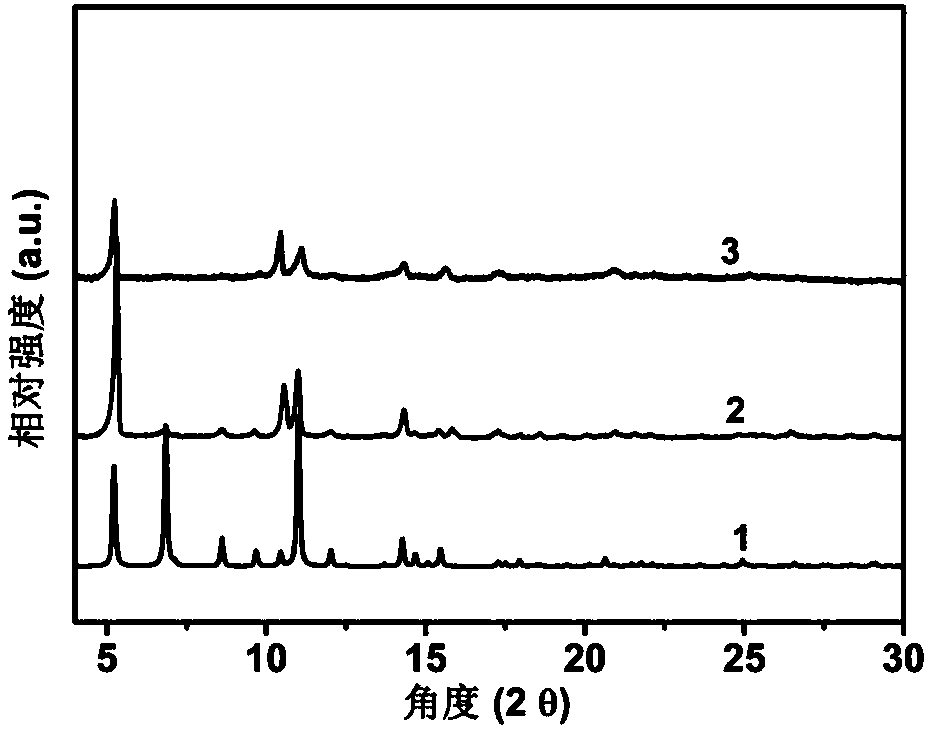

[0035] 30mg of N,N'-bis(3,5-dicarboxybenzene)-1,4,5,8-naphthalimide obtained in Example 1 and 36mg of Cu(NO 3 ) 2 ·3H 2 O is soluble in N,N'-dimethylformamide (DMF) / dioxane / H 2 O (5mL, volume ratio is 3:1:1) mixed solvent, then add 80μL of concentrated HCl, place it in a 20mL bacterial seed bottle, seal it and put it in a 80℃ oven to react for 72h, take it out and wash it repeatedly with DMF , The optical microscope showed a square green crystal, which is the prepared Cu-organic framework material. Its structure is determined by Agilent Technologies SuperNova single crystal diffractometer. The test results show that the crystal structure is [Cu 2 (C 30 H 10 N 2 O 12 )(H 2 O) 2 ](C 3 H 7 NO) 5 (H 2 O) 3 , Belongs to tetragonal crystal system, space group is P42 1 2. The unit cell parameters are α=β=γ=90°, the unit cell volume is Z=8, D c ...

Embodiment 3

[0050] This embodiment relates to a method for preparing a homogeneous Co-organic framework, which specifically includes the following steps:

[0051] The 30mg of N,N'-bis(3,5-dicarboxybenzene)-1,4,5,8-naphthalimide obtained in Example 1 and 45mg of Co(NO 3 ) 2 ·6H 2 O is soluble in N,N'-diethylformamide (DEF) / methanol / H 2 O (5mL, volume ratio: 3:1:1) mixed solvent, then add 80μL of concentrated HCl, place it in a 20mL bacterial seed bottle, seal it and put it in a 80℃ oven to react 72, take it out and repeatedly wash with DEF , Get the metal organic frame material.

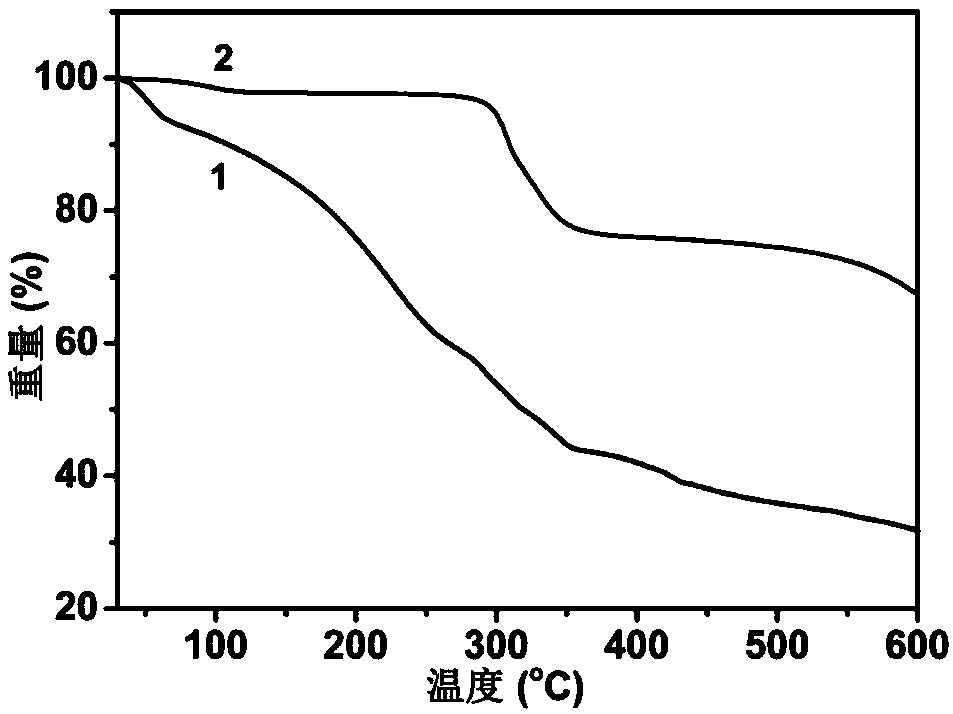

[0052] The metal-organic framework material obtained in this example was solvent exchanged with anhydrous acetone. The solvent was exchanged every half an hour, at least ten times, and then activated under vacuum and 25°C for 12 hours, and then activated at 100°C In 12 hours, a metal organic framework material with unsaturated metal sites and open channels was obtained. The MicromeriticsASAP 2020 specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com