Continuous-leaching bioleaching device and method for red mud

A technology of bioleaching and red mud, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unfavorable bioleaching efficiency, inability to carry out large-scale industrial application, and improvement, and achieve improvement The effect of leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

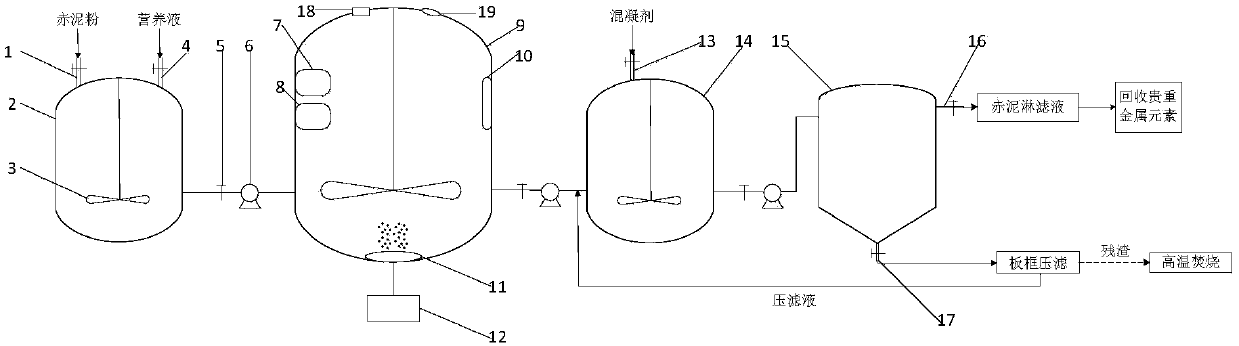

[0065] The effective volume of the batching tank is 30L, and the material is 304 stainless steel. The dry red mud is ground and passed through 100 mesh. The nutrient solution uses deionized water as the solvent, and the composition ratio of the nutrient solution is: 10% sucrose, 0.02% yeast extract, 0.02% beef extract, KNO 30.05%, the solvent is deionized water. Add red mud powder and nutrient solution into the batching tank and mix evenly. The initial dosage of red mud powder is 300g. The nutrient solution is sterilized at 121°C and 103kPa and the batching tank is filled up.

[0066] The effective volume of the leaching tank is 30L, and the material is 304 stainless steel. In the leaching tank, the start-up phase is carried out first in batch mode of operation. The mixed slurry in the batching tank enters the leaching tank through a flow pump. When the mixed slurry is full of the leaching tank, open the inoculation cover and add 60 mL of activated Aspergillus niger spore s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com