A kind of preparation method of polyoxometalate-based composite visible light catalyst

A polyoxometalate and visible light technology, applied in the field of photocatalytic materials, can solve the problem of low visible light response, and achieve the effects of high visible light activity, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation method of AgHPMo:

[0033] (1) Dissolve 0.376g of silver nitrate in 10ml of distilled water, stir until completely dissolved to obtain reaction solution A; dissolve 0.5g of phosphomolybdic acid in 5ml of distilled water, stir magnetically, and fully dissolve to obtain reaction solution B;

[0034] (2) Add solution B dropwise to solution A, silver phosphomolybdate suspension, move the solution to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 140°C for 2 hours, centrifuge, wash 3 times with distilled water, and dry to obtain AgHPMo (molar ratio of silver nitrate to phosphomolybdic acid 1:10).

[0035] 2. AgHPMo / Ag 3 VO 4 Preparation:

[0036] (1) Dissolve 0.376g of silver nitrate in 10ml of distilled water, stir until completely dissolved to obtain reaction solution A; dissolve 0.5g of phosphomolybdic acid in 5ml of distilled water, stir magnetically, and fully dissolve to obtain reaction solution B;

[0037] (2) Solution B is added...

Embodiment 2

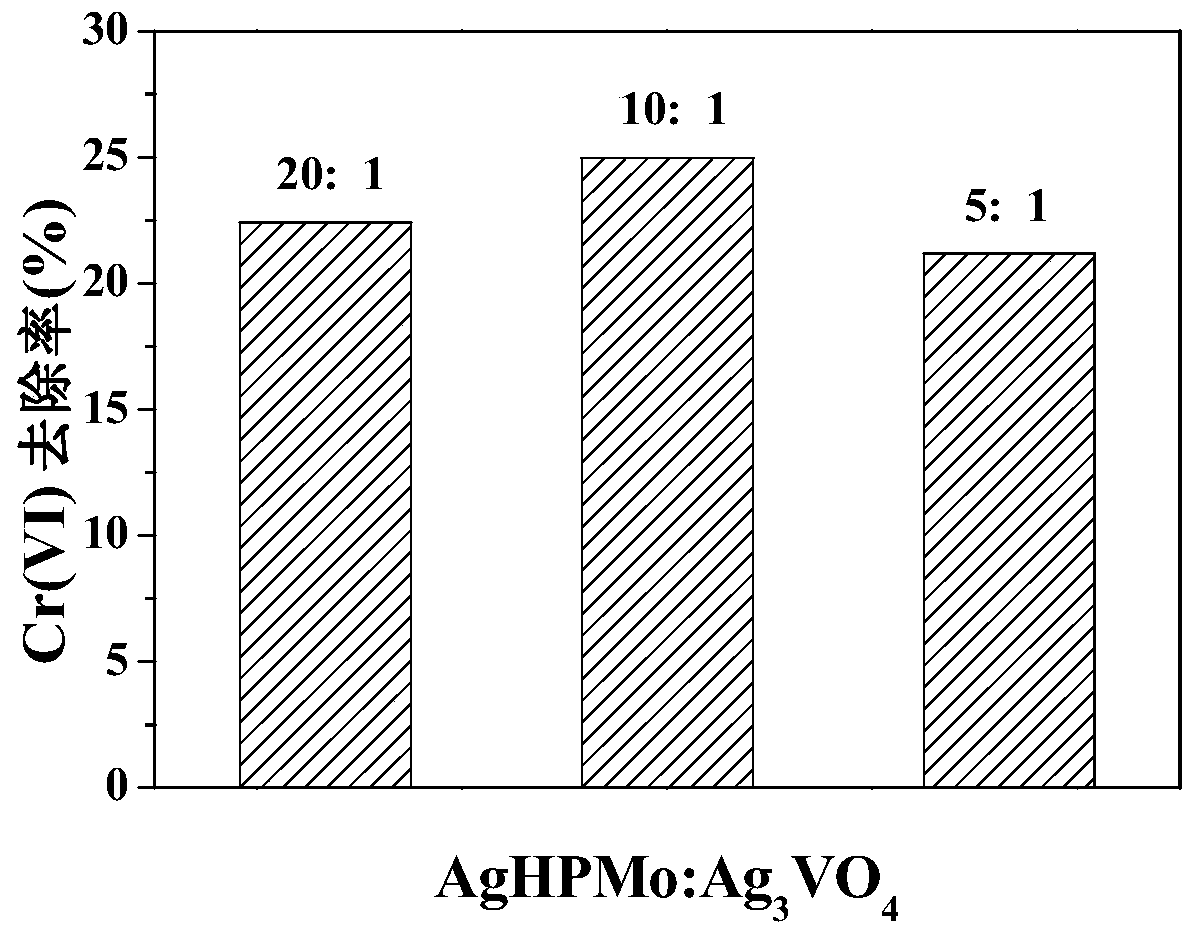

[0048] The amount of sodium vanadate added will affect the Ag in the catalyst 3 VO 4 The content will also affect the dispersibility of the catalyst during preparation. Change AgHPMo / Ag in embodiment 1 3 VO 4 In the preparation method, the amount of sodium vanadate added, that is, the molar ratio of silver phosphomolybdate to silver vanadate, is used to prepare a series of catalysts.

[0049] Taking the degradation of chromium-containing Cr(VI) wastewater as an example to test the catalyst activity, add 50 mL of chromium-containing Cr(VI) wastewater with a concentration of 80 μmol / L to the reactor, and add 50 mg of AgHPMo / Ag prepared in different proportions 3 VO 4 Visible light catalyst, adjust pH = 2, continue to stir, stir in the dark for 30 minutes to adsorption equilibrium, turn on the visible light source, and take samples at intervals of 30 minutes.

[0050] Such as figure 1 , when the molar ratio of silver phosphomolybdate and silver vanadate is 1:10, the removal...

Embodiment 3

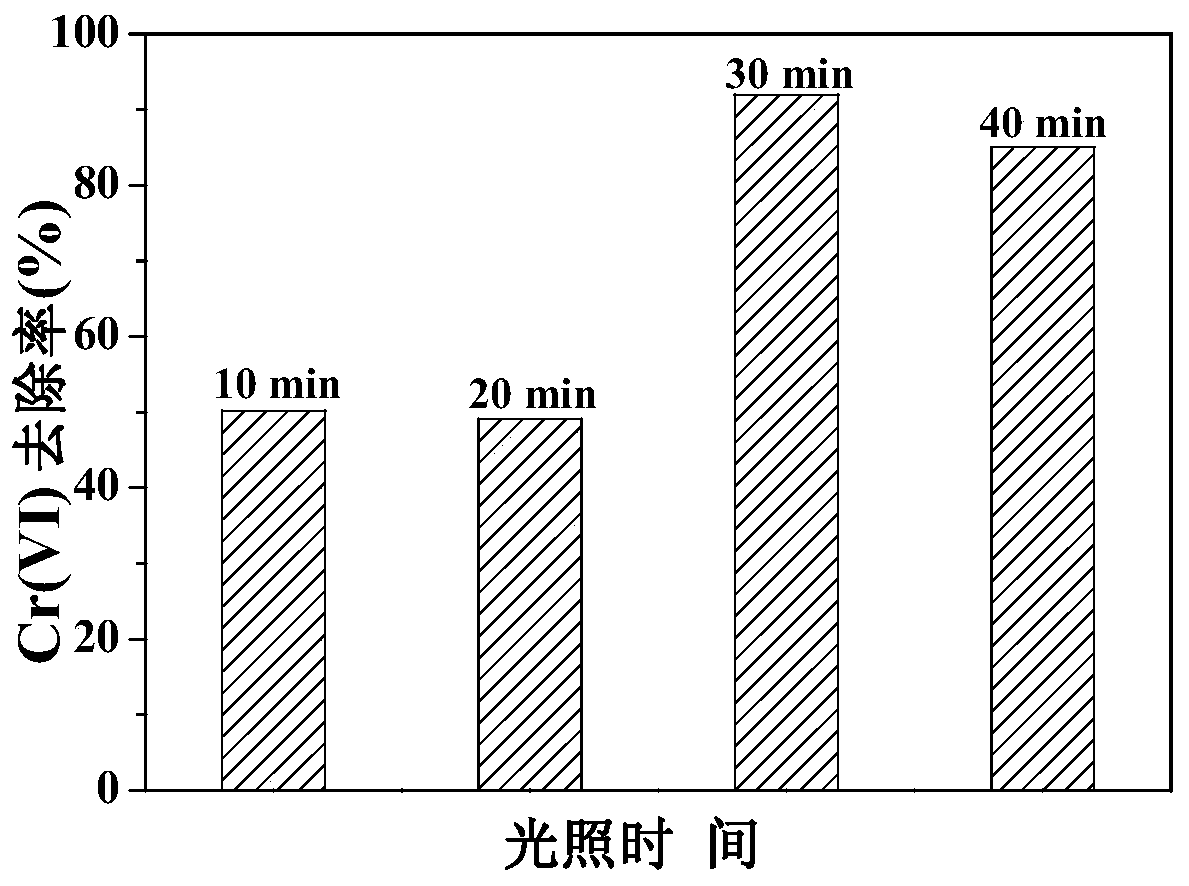

[0052] Adjusted different light time will affect the formation of simple Ag, the lack of simple Ag in the composite catalyst may lead to low reduction efficiency, and too much simple Ag will inhibit the formation of AgHPMo and Ag. 3 VO 4 The effect of the heterojunction, which leads to a decrease in the efficiency of reducing Cr(VI), so we can change the Ag@AgHPMo / Ag in Example 1 3 VO 4 In the preparation method, different illumination times are adjusted, a series of catalysts are prepared, and the chromium reduction operation in Example 2 is compared to obtain figure 2 .

[0053] Depend on figure 2 It can be seen that the reduction effect of Cr(VI) is the best when the light time is 30min, so the Ag@AgHPMo / Ag prepared by reducing for 30min 3 VO 4 The photocatalytic activity is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com