Method for producing sintered bricks by using industrial wastes as raw material

A technology for industrial waste and sintered bricks, applied in the field of sintered brick production, can solve problems such as low production efficiency and demoulding, and achieve the effects of improving efficiency, reducing production costs, and improving cold-pressing forming processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

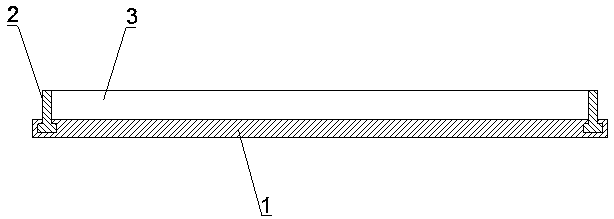

Image

Examples

Embodiment 1

[0029] A. Collect blast furnace slag, steel slag, non-ferrous metal slag, chemical iron slag, coal gangue, mineral processing waste rock, washing waste slag, tailings, coal slag, flue ash, coal powder slag, shale ash, sulfuric acid ore slag, calcium carbide Several kinds of slag, alkali slag, gas slag, phosphorus slag, mercury slag, chromium slag, salt sludge, sludge, boron slag;

[0030] B. Pulverize various industrial wastes into particles with a particle size of less than 1.5mm, and then put them into a mixer for stirring. The speed of the mixer is 260r / min, and the mixing time is 20min;

[0031] C. Evenly mix the industrial waste particles with water in a volume ratio of 1.5:1, and then age for 4h;

[0032] D. Weigh clay and cement, and mix clay, cement, and aged industrial waste particles with water evenly to obtain a mixture, wherein the weight ratio of clay, cement, and industrial waste particles to water is 10:5: 65:20;

[0033]E. Transfer the mixed material into the...

Embodiment 2

[0037] A. Collect blast furnace slag, steel slag, non-ferrous metal slag, ferrous slag, coal gangue, beneficiation waste rock, beneficiation waste slag, tailings, coal slag, flue ash, coal powder slag, shale ash, sulfate ore slag, calcium carbide Slag, alkali slag, gas furnace slag, phosphorus slag, mercury slag, chromium slag, salt mud, sludge, boron slag;

[0038] B. Crush various industrial wastes into particles with a particle size of less than 1.5mm, and then put them into a blender for stirring. The speed of the blender is 280r / min, and the stirring time is 17min;

[0039] C. Mix industrial waste particles and water uniformly at a volume ratio of 1.8:1, and then age for 4.5 hours;

[0040] D. Weigh the clay and cement, mix the clay, cement, and aged industrial waste particles with water evenly to obtain a mixture, wherein the weight ratio of clay, cement, industrial waste particles to water is 12:7: 70:25;

[0041] E. Transfer the mixed material into the mold. The mold...

Embodiment 3

[0045] A. Collect blast furnace slag, steel slag, non-ferrous metal slag, ferrous slag, coal gangue, beneficiation waste rock, beneficiation waste slag, tailings, coal slag, flue ash, coal powder slag, shale ash, sulfate ore slag, calcium carbide Slag, alkali slag, gas furnace slag, phosphorus slag, mercury slag, chromium slag, salt mud, sludge, boron slag;

[0046] B. Crush various industrial wastes into particles with a particle size of less than 1.5mm, and then put them into the mixer for stirring. The speed of the mixer is 300r / min, and the stirring time is 15min;

[0047] C. Mix industrial waste particles and water uniformly at a volume ratio of 2:1, and then age for 5 hours;

[0048] D. Weigh the clay and cement, mix the clay, cement, aged industrial waste particles and water evenly to obtain a mixture, wherein the weight ratio of clay, cement, industrial waste particles to water is 15:10: 80:30;

[0049] E. Transfer the mixed material into the mold. The mold is equipp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com