A method of extracting isopentane from naphtha

A naphtha, isopentane technology, applied in chemical instruments and methods, hydrocarbon purification/separation, adsorption purification/separation, etc., can solve the problem of high energy consumption, achieve lower energy consumption, flexible control, and large operation flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

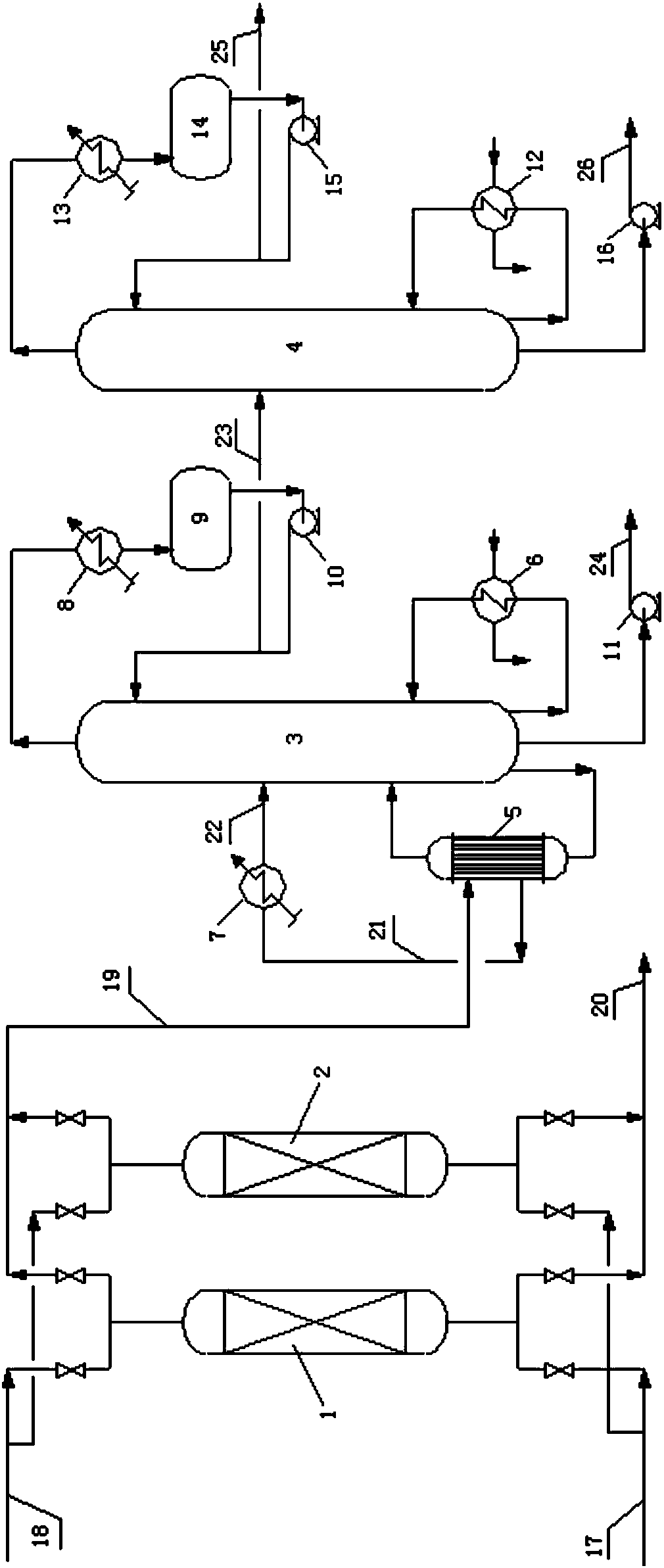

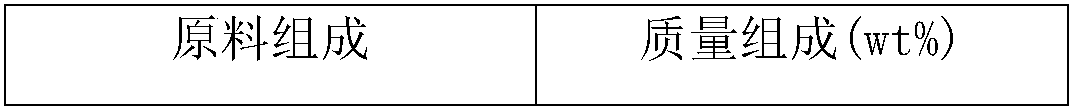

[0022] as per figure 1 The shown method extracts isopentane from naphtha, and the composition of the feedstock is shown in Table 1.

[0023] Table 1

[0024] Raw material composition

[0025] The vaporized naphtha raw material enters the adsorption tower, and there are two adsorption towers, which are used alternately for adsorption and desorption, and operate continuously. The adsorbent is 5A molecular sieve, and the desorbent is nitrogen. The adsorption pressure is 1.0MPa in gauge pressure, and the adsorption temperature is 200°C. After determination, the composition of the material at the top outlet of the adsorption tower is shown in Table 2.

[0026] Table 2

[0027]

[0028]

[0029] The top material of the adsorption tower enters the reboiler of the weight removal tower to heat the material in the tower kettle, and the outlet temperature is 124°C, and then cools to about 80°C in the feed cooler of the weight removal tower and enters the middle of the...

Embodiment 2

[0034] According to the method and steps of Example 1, the vaporized naphtha raw material enters the adsorption tower, and there are two adsorption towers, and the adsorption and desorption are alternately used and operated continuously. The adsorbent is 5A molecular sieve, and the desorbent is H 2 . The adsorption pressure is 0.5MPa in gauge pressure, and the adsorption temperature is 150°C. After determination, the composition of the material at the top outlet of the adsorption tower is shown in Table 4.

[0035] Table 4

[0036]

[0037]

[0038] The top material of the adsorption tower enters the reboiler of the deweighting tower to heat the material in the tower kettle, the outlet temperature is 95°C, and then cools to about 60°C in the feed cooler of the deweighting tower and enters the middle of the deweighting tower. The weight-removing column has 50 trays, the operating pressure is 0.1MPa in gauge pressure, the temperature at the top of the tower is 38.2°C, t...

Embodiment 3

[0043] According to the method and steps of Example 1, the vaporized naphtha raw material enters the adsorption tower, and there are two adsorption towers, and the adsorption and desorption are alternately used and operated continuously. The adsorbent is 5A molecular sieve, and the desorbent is CO 2 . The adsorption pressure is 1.5MPa in gauge pressure, and the adsorption temperature is 250°C. After determination, the composition of the material at the top outlet of the adsorption tower is shown in Table 6.

[0044] Table 6

[0045]

[0046]

[0047]The top material of the adsorption tower enters the reboiler of the deweighting tower to heat the material in the tower kettle, the outlet temperature is 120°C, and then cools to about 80°C in the feed cooler of the deweighting tower and enters the middle of the deweighting tower. The weight removal tower has 88 trays, the operating pressure is 0.3MPa in gauge pressure, the temperature at the top of the tower is 63.9°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com