LIM low-oil-powder-separation high-electric-conductive silicone rubber composition and preparation method of same

A silicone rubber composition, high conductivity technology, applied in the field of LIM low oil powder separation high conductivity silicone rubber composition and its preparation, can solve problems such as oil powder separation, to improve production efficiency, improve conductivity stability and pass rate , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a LIM low-oil powder separation high-conductivity silicone rubber composition, comprising the following steps:

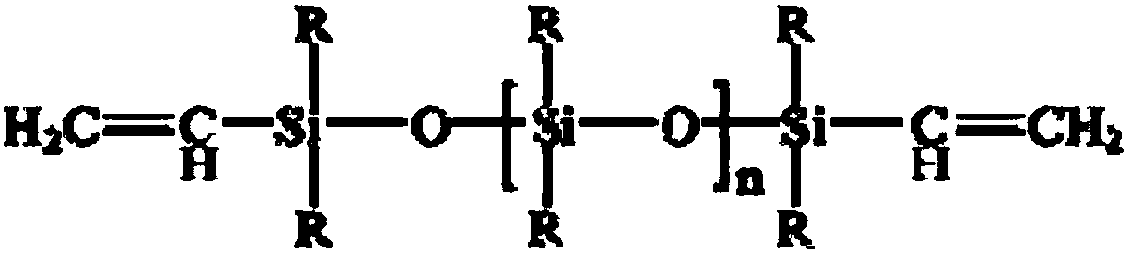

[0053] Step 1: Base rubber preparation: 50 parts by mass of vinyl-terminated silicone oil of 10000mPa·s, 20 parts by mass of vinyl-terminated silicone oil with a specific surface area of 300mPa 2 / g of fumed silica, 5 parts by mass of hexamethylsilazane and 1 part by mass of water were added to the kneader, stirred at room temperature for 1 hour, then heated to 150°C and continued to stir for 2 hours, and finally added 50 parts by mass of Dilute with 10000mPa·s vinyl-terminated silicone oil, and obtain base rubber after cooling;

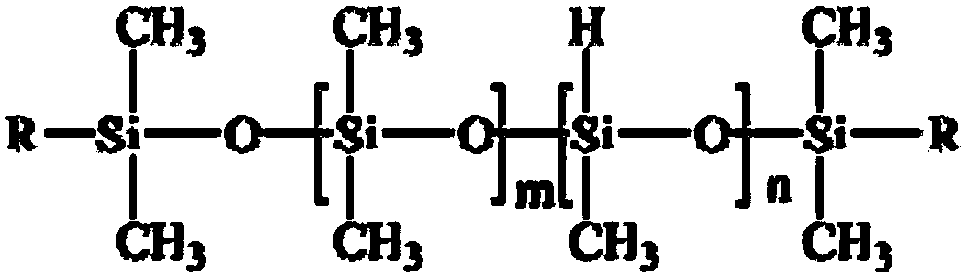

[0054] Step 2: Preparation of component A: Add 100g of the base glue prepared in step 1, 55.88g of 20um silver-coated glass powder, 223.52g of 45um silver-coated glass powder, 4.19g of vinyltriethoxysilane A151, and 18.73g in a planetary mixer D40 solvent oil, 0.27g Castel platinum catalyst (3000ppm), warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com