Mesoporous nano-crystal tungsten trioxide electrochromic energy-storing film and preparation method thereof

A tungsten trioxide and electrochromic technology, applied in the direction of coating, etc., can solve the problems of low capacity, poor cycle performance, slow discoloration speed, etc., achieve high capacity, satisfy performance and life, and inhibit volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

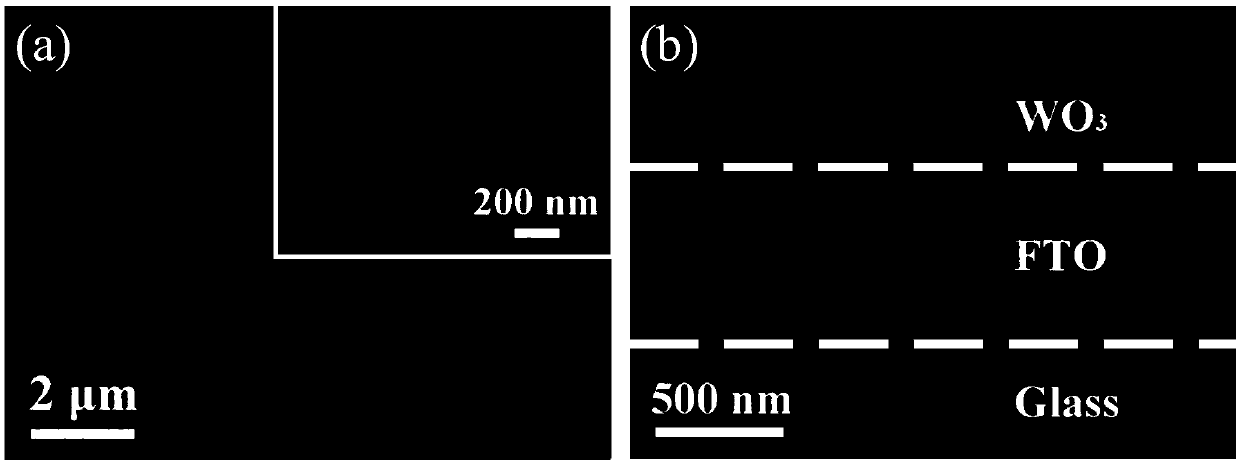

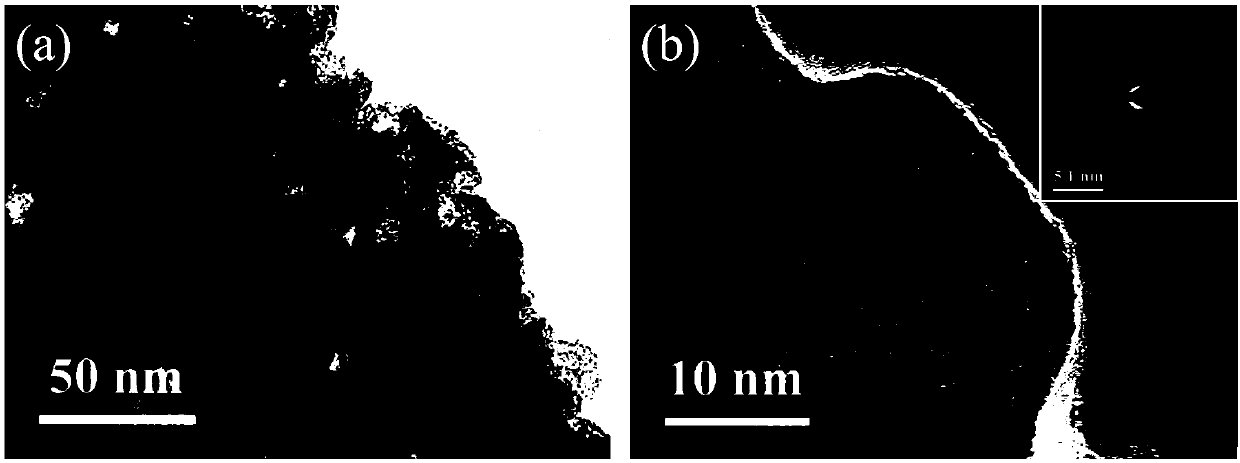

[0035] (1) FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr> 85%) Use acetone, deionized water and ethanol to clean ultrasonically for 10 minutes, and blow clean with nitrogen to obtain clean FTO conductive glass;

[0036] (2) Combine 2.3793g tungsten hexachloride and 2.3436g F127 (Pluronic F127, EO 106 -PO 70 -EO 106 ,M w =12600, Aldrich) was added to 30ml absolute ethanol and stirred to form solution A, WCl 6 The concentration in solution A is 0.2mol L -1 , The concentration of F127 in solution A is 6.2mmol L -1 ;

[0037] (3) The solution A obtained in step (2) is aged in a water bath at 45°C for 24 hours to form a dip coating solution;

[0038] (4) Insert the clean FTO conductive glass vertically into the dipping solution, and set it to 4mm s -1 Pull at a constant speed until the FTO conductive glass completely leaves the solution to obtain FTO conductive glass covered with a sol film;

[0039] (5) Transfer the sol film obtained in step (4) to an ...

Embodiment 2

[0046] (1) FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr> 85%) Use acetone, deionized water and ethanol to clean ultrasonically for 10 minutes, and blow clean with nitrogen to obtain clean FTO conductive glass;

[0047] (2) Add 2.974g tungsten hexachloride and 3.024g F127 to 30ml absolute ethanol and stir to form solution A, WCl 6 The concentration in solution A is 0.25 mol L -1 , The concentration of F127 in solution A is 8mmol L -1 ;

[0048] (3) The solution A obtained in step (2) is aged in a water bath at 50°C for 22 hours to form a dip coating solution;

[0049] (4) Insert the cleaned FTO conductive glass vertically into the dip coating solution, and set it to 6mm s -1 Pull at a constant speed until the FTO conductive glass completely leaves the solution to obtain FTO conductive glass covered with a sol film;

[0050] (5) Transfer the sol film obtained in step (4) to an oven and dry it at 50°C for 22 hours to form a gel film;

[0051] (6) The ...

Embodiment 3

[0057] (1) FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr> 85%) Use acetone, deionized water and ethanol to clean ultrasonically for 10 minutes, and blow clean with nitrogen to obtain clean FTO conductive glass;

[0058] (2) Add 3.57g tungsten hexachloride and 3.78g F127 to 30ml absolute ethanol and stir to form solution A, WCl 6 The concentration in solution A is 0.3mol L -1 , The concentration of F127 in solution A is 10mmol L -1 ;

[0059] (3) The solution A obtained in step (2) is aged in a water bath at 55°C for 20 hours to form a dip coating solution;

[0060] (4) Insert the clean FTO conductive glass vertically into the dipping solution, and set it to 8mm s -1 Pull at a constant speed until the FTO conductive glass completely leaves the solution to obtain FTO conductive glass covered with a sol film;

[0061] (5) Transfer the sol film obtained in step (4) to an oven and dry it at 60°C for 18 hours to form a gel film;

[0062] (6) The gel film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com