Semi-flexible pavement material and paving method capable of quickly opening traffic for semi-flexible pavement

A semi-flexible pavement and pavement technology, which is applied to cohesive pavement paved on site, buildings, roads, etc., can solve the problems of long closed traffic time, long solidification time, and long curing time on urban roads, and avoid particle interference , The effect of simple construction process and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

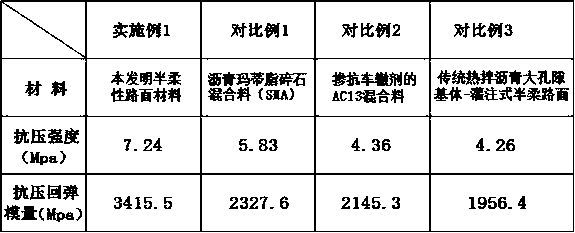

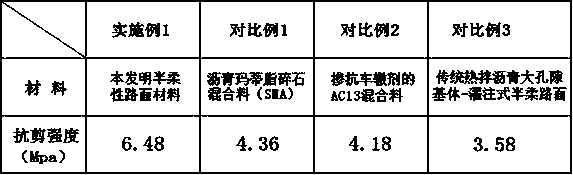

Examples

Embodiment 1

[0032] Embodiment 1: A semi-flexible pavement material, including a porous mixture and a cement-based grout for filling in the pores of the porous mixture; the porous mixture includes 4 parts by mass of bisphenol A ring Oxygen resin, 3 parts of absolute ethanol, 3 parts of ethylene glycol monobutyl ether, 5 parts of diethanolamine, 10 parts of SBR styrene-butadiene latex, 65 parts of coarse aggregate, 15 parts of fine aggregate and 35 parts of mineral powder; the cement The base grouting material includes 35 parts by mass of fly ash portland cement, 15 parts of S95 water-quenched blast furnace slag powder, 1 part of sodium chloride, 1 part of waste tire rubber powder, 10 parts of naphthalene-based high-efficiency water reducer, 1 Part polyether shrinkage reducing agent, 0.5 part of carbonate inorganic salt, 3 parts of nonionic surfactant and 20 parts of water.

[0033] A semi-flexible pavement method that can be quickly opened to traffic:

[0034] 1) Preparation of porous mix...

Embodiment 2

[0041] Embodiment 2: A semi-flexible pavement material, including a porous mixture and a cement-based grout for filling in the pores of the porous mixture; the porous mixture includes 8 parts by mass of bisphenol A ring Oxygen resin, 6 parts of absolute ethanol, 6 parts of ethylene glycol monobutyl ether, 10 parts of diethanolamine, 15 parts of SBR styrene-butadiene latex, 75 parts of coarse aggregate, 20 parts of fine aggregate and 40 parts of mineral powder; the cement-based The grouting material includes 45 parts of fly ash Portland cement, 20 parts of S105 water-quenched blast furnace slag powder, 5 parts of calcium chloride, 3 parts of waste tire rubber powder, 15 parts of sulfamate superplasticizer, 5 parts of polyether shrinkage reducer, 3 parts of acetic acid inorganic salt, 6 parts of polymer defoamer and 25 parts of water.

[0042] A semi-flexible pavement method that can be quickly opened to traffic:

[0043] 1) Preparation of porous mixture

[0044] Mix 8 parts o...

Embodiment 3

[0050] Embodiment 3: A kind of semi-flexible pavement material, comprises porous mixture and is used to fill in the cement-based grouting material that is used in conjunction with the pores of the porous mixture; The porous mixture includes 5 parts of bisphenol A rings in parts by mass Oxygen resin, 4.5 parts of absolute ethanol, 4.5 parts of ethylene glycol monobutyl ether, 8 parts of diethanolamine, 13 parts of SBR styrene-butadiene latex, 70 parts of coarse aggregate, 18 parts of fine aggregate and 38 parts of mineral powder; the cement The base grouting material includes 40 parts by mass of fly ash Portland cement, 17 parts of S95 water-quenched blast furnace slag powder, 3 parts of sodium nitrate, 2 parts of waste tire rubber powder, 13 parts of polycarboxylate high-performance water reducer, 3 parts of polyether shrinkage reducer, 1.5 parts of acetic acid inorganic salt, 4.5 parts of silicone defoamer and 23 parts of water.

[0051] A semi-flexible pavement method that c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com