Continuous preparation method of sodium dicyanamide

A technology of dicyandiamide sodium and cyanogen halide, applied in the field of continuous preparation of dicyandiamide sodium, can solve the problems of dicyandiamide sodium production process with many impurities, low yield, unstable quality, etc., and achieve simple post-treatment process, Easy to get raw materials and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

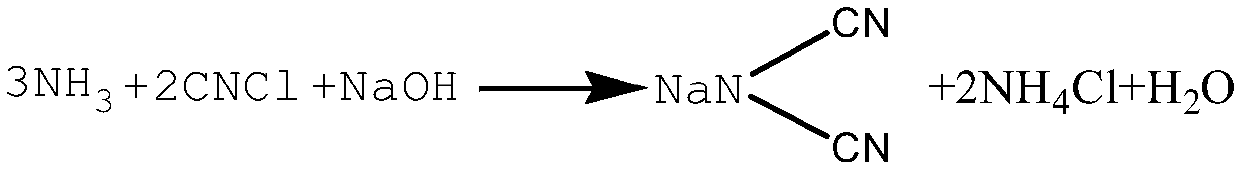

[0017] The embodiment of the present invention provides a continuous preparation method of sodium dicyandiamide, the preparation method at least includes the following steps:

[0018] Step 1, ammonia water and cyanogen halide are mixed in a pre-reactor under the condition of 0-20° C. to react to obtain a mixed material, and the pH value of the mixed material is 6-9;

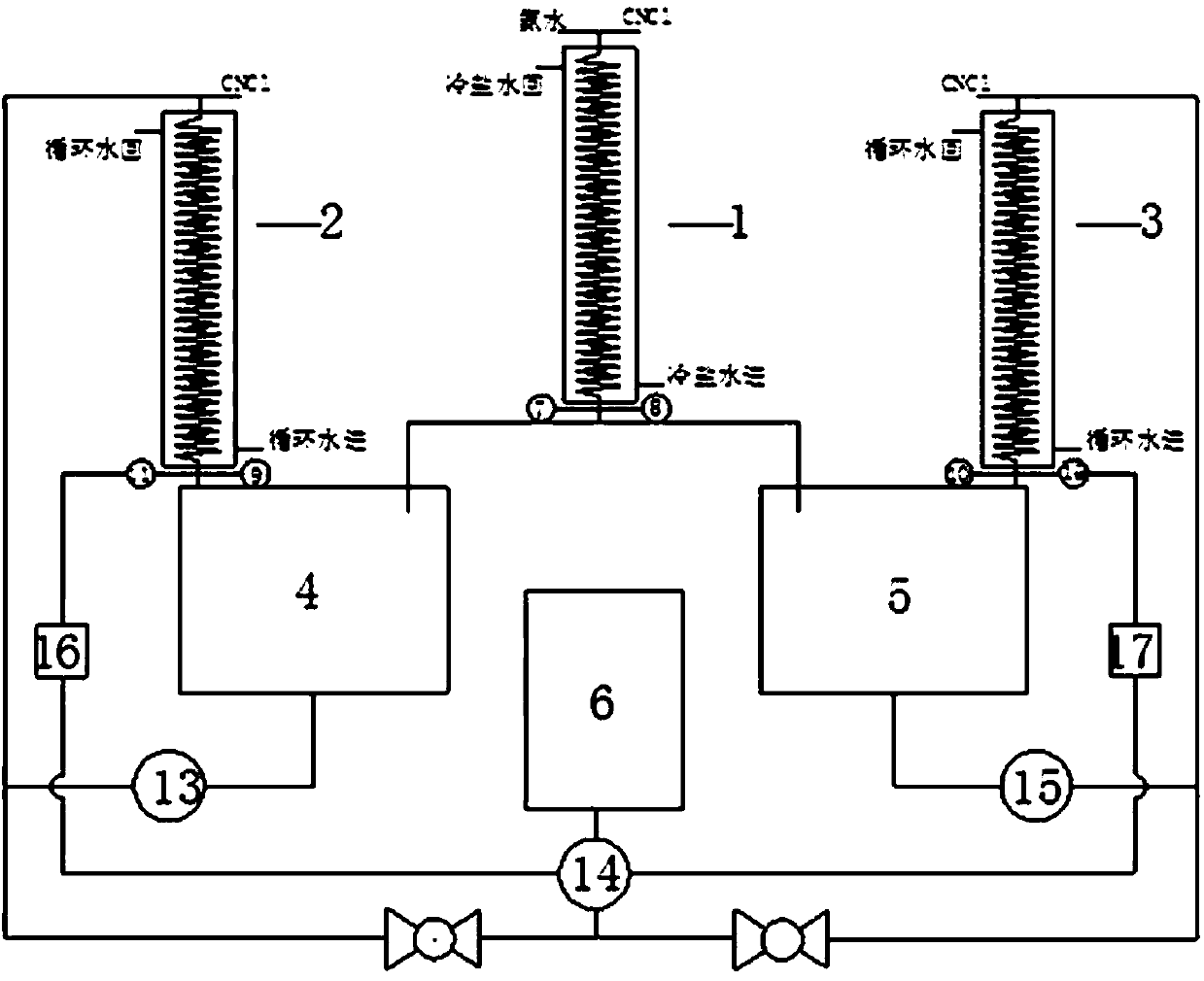

[0019] Step 2, providing a reactor, the reactor is provided with a reactor connected to each other, a condensation tube reactor and a liquid caustic storage tank, the mixed material is transported to the reactor of the reactor, and the mixed material is mixed in the reactor The temperature is between 0-50°C;

[0020] Step 3, pump the mixed material and sodium hydroxide solution into the condensing tube reactor, adjust the pH value of the mixed material to 7-10, and at the same time pass the halogenation into the condensing tube reactor Cyanide is reacted, and the reaction solution falls back into the reaction ke...

Embodiment 1

[0042] The present embodiment provides a kind of continuous preparation method of sodium dicyandiamide, process flow diagram refers to attached figure 1 , the preparation method at least includes the following steps:

[0043] Step 1, adopt metering pump to mass concentration in tubular reactor to be 1000g of ammoniacal liquor 15%, ammoniacal liquor feed rate is 10g / min, when starting to add ammoniacal liquor, feed cyanogen chloride gas in tubular reactor at 0 Reaction under the condition of -5°C to obtain the mixed material, adjust the speed of the introduction of cyanogen chloride, and when the pH value of the mixed solution is 7.5-8, transport the mixed material to the intermediate tank;

[0044] Step 2. The temperature of the mixed material in the intermediate tank is kept at 40-50° C., and the mixed material is passed through the intermediate tank by a peristaltic pump into a tube condenser connected to the intermediate tank, and in the tube condenser Carry out circulatio...

Embodiment 2

[0048]The present embodiment provides a kind of continuous preparation method of sodium dicyandiamide, process flow diagram refers to attached figure 1 , the preparation method at least includes the following steps:

[0049] Step 1, adopt metering pump to mass concentration in tubular reactor to be 1000g of ammoniacal liquor 15%, ammoniacal liquor feed rate is 15g / min, when beginning to add ammoniacal liquor, feed cyanogen chloride gas in tubular reactor at 10 Reaction under the condition of -15°C to obtain the mixed material, adjust the speed of the introduction of cyanogen chloride, and when the pH value of the mixed solution is 6-7.5, transport the mixed material to the intermediate tank;

[0050] Step 2. The temperature of the mixed material in the intermediate tank is kept at 30-40° C., and the mixed material is passed through the intermediate tank into a tube condenser connected to the intermediate tank with a peristaltic pump, and is cooled in the tube condenser. Carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com