Waterborne acrylic resin coating with chloride ion corrosion resistance and preparation method of waterborne acrylic resin coating

A water-based acrylic acid and chloride ion corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor adhesion, environmental protection, poor resistance to chloride ion corrosion, etc., and achieve improved density, uniform distribution, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

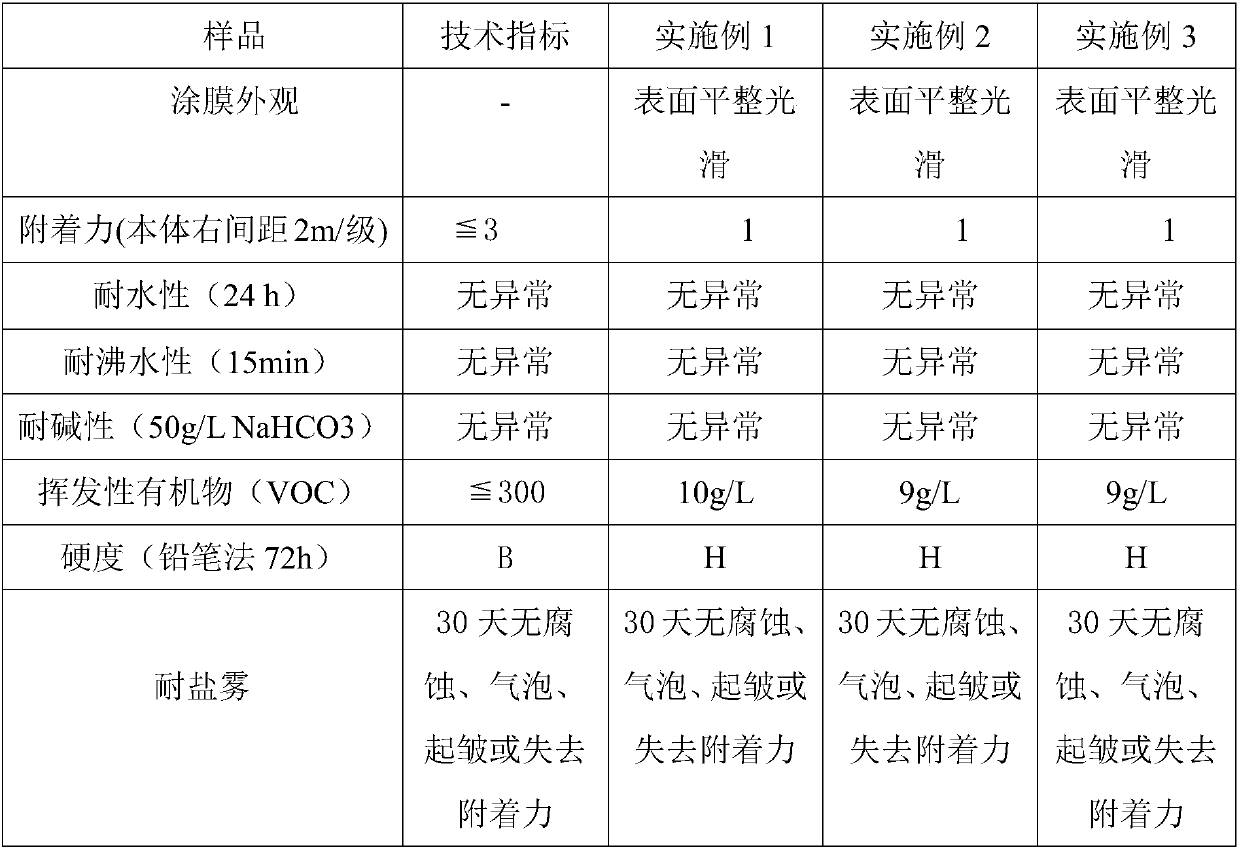

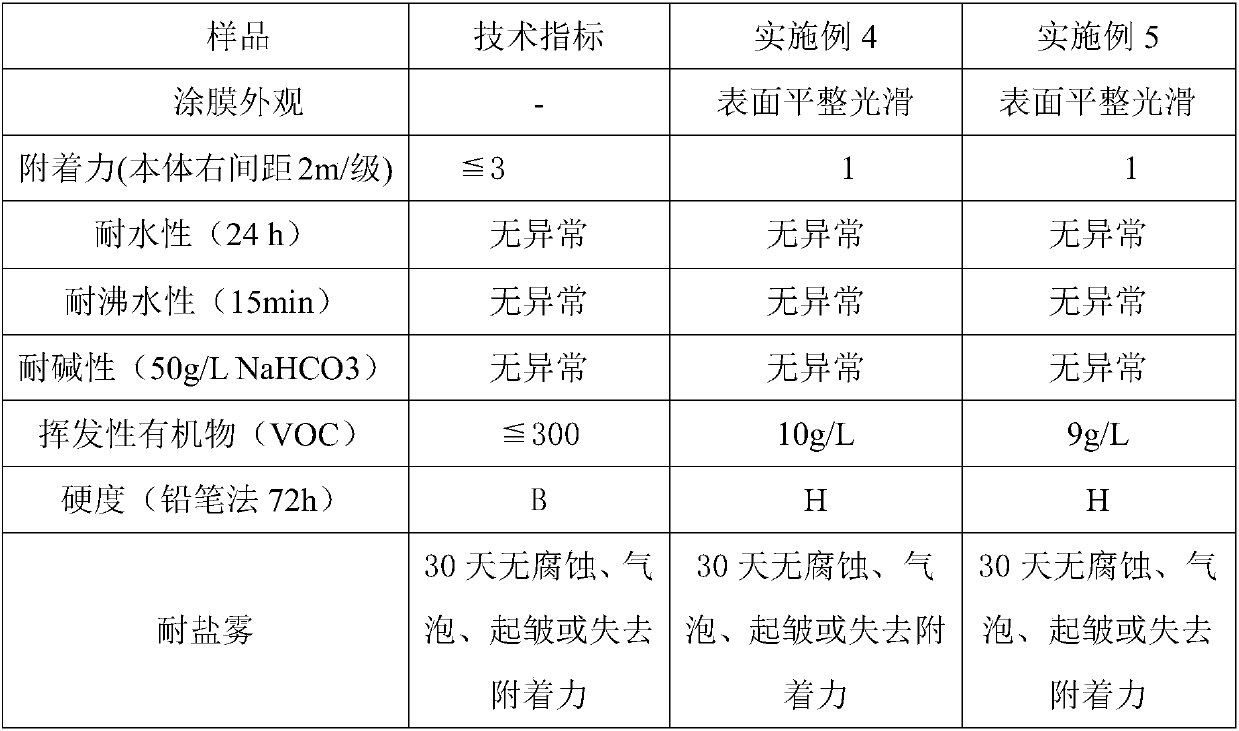

Embodiment 1

[0024] The water-based acrylic resin coating of the present embodiment anti-chloride ion corrosion comprises the raw material of following weight portion: 30 parts of water-based acrylic resins, 9 parts of nano-calcium carbonates, 9 parts of nano-silicon nitride powders, 9 parts of nano-alumina powders, dodecyl 5 parts of sodium benzenesulfonate, 3 parts of nicotine, 2 parts of anti-settling agent, 2 parts of tributyl citrate, 25 parts of filler, 2 parts of additives, 10 parts of deionized water;

[0025] The filler is glass microspheres; the additive is a mixture of leveling agent, preservative, antifungal agent and dispersant;

[0026] The preparation method of the waterborne acrylic resin coating of the anti-chloride ion corrosion of the present embodiment may further comprise the steps:

[0027] S1. Weighing each raw material according to parts by weight;

[0028] S2. Mix nano-calcium carbonate, nano-silicon nitride powder, nano-alumina powder and sodium dodecylbenzene su...

Embodiment 2

[0031] The water-based acrylic resin coating of the present embodiment anti-chloride ion corrosion comprises the raw material of following weight portion: 50 parts of water-based acrylic resins, 14 parts of nano-calcium carbonates, 14 parts of nano-silicon nitride powders, 14 parts of nano-alumina powders, dodecyl 10 parts of sodium benzenesulfonate, 8 parts of nicotine, 4 parts of anti-settling agent, 6 parts of tributyl citrate, 40 parts of filler, 6 parts of additives, 20 parts of deionized water;

[0032] The filler is a mixture of glass microspheres, fly ash microspheres, sericite powder, titanium dioxide, and calcined kaolin; the additives are a mixture of leveling agents, preservatives, antifungal agents, dispersants, defoamers, and rheological agents. made;

[0033] The preparation method of the waterborne acrylic resin coating of the anti-chloride ion corrosion of the present embodiment may further comprise the steps:

[0034] S1. Weighing each raw material according...

Embodiment 3

[0038] The water-based acrylic resin coating of the present embodiment anti-chloride ion corrosion comprises the raw material of following weight portion: 40 parts of water-based acrylic resins, 12 parts of nano-calcium carbonates, 11 parts of nano-silicon nitride powders, 12 parts of nano-alumina powders, dodecyl 7 parts of sodium benzenesulfonate, 5.5 parts of nicotine, 3 parts of anti-settling agent, 4 parts of tributyl citrate, 32 parts of filler, 4 parts of additives, 15 parts of deionized water;

[0039] The filler is a mixture of glass microspheres, fly ash microspheres, and sericite powder; the additives are a mixture of leveling agents, preservatives, dispersants, and defoamers;

[0040] The preparation method of the waterborne acrylic resin coating of the anti-chloride ion corrosion of the present embodiment may further comprise the steps:

[0041] S1. Weighing each raw material according to parts by weight;

[0042] S2. Mix nano-calcium carbonate, nano-silicon nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com