Desulfurization device and method for low temperature methanol washing circulating methanol partition extractive distillation tower

A technology of extractive distillation tower and low-temperature methanol washing, which is applied in the field of coal chemical industry, can solve the problem of excessive sulfur content in purified gas, and achieve the effect of reducing equipment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

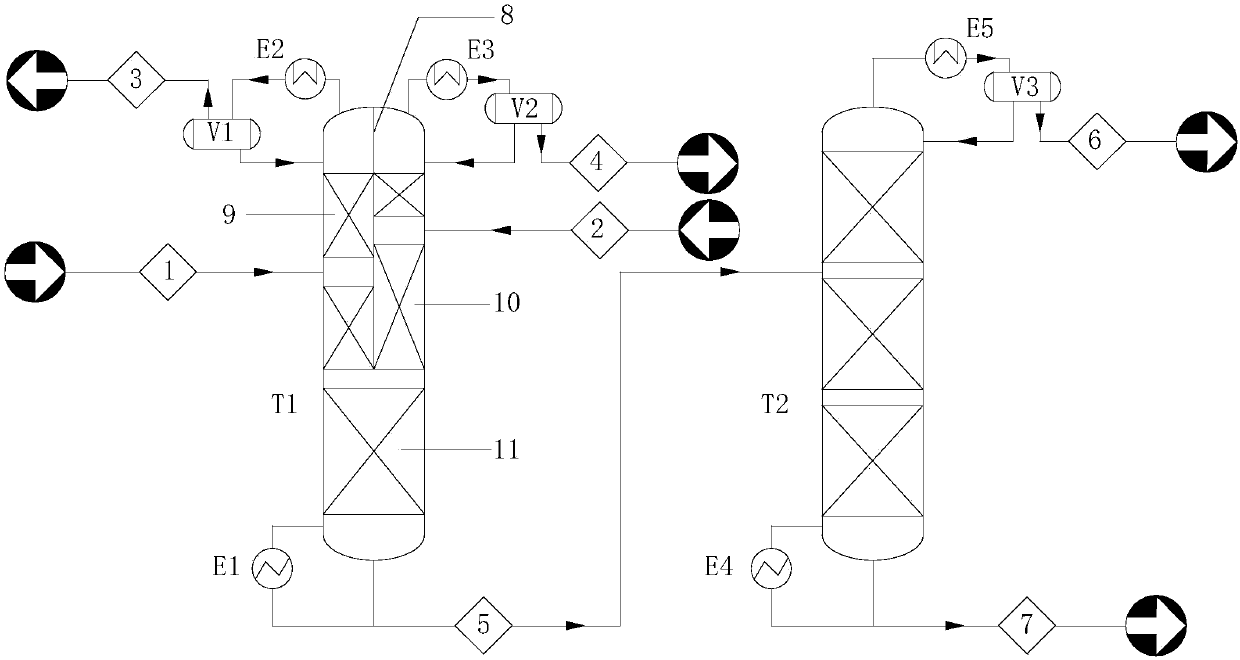

[0040] A device and method for desulfurization of a low-temperature methanol washing cycle methanol partition extraction rectification tower, specifically as follows:

[0041] Sulfur-rich methanol comes from the pre-wash section of low-temperature methanol washing, characterized by methanol 95.40553% (wt%), carbonyl sulfide 0.00216%, hydrogen sulfide 0.043%, methyl mercaptan 0.00405%, ethanethiol 0.0136%, n-propylene mercaptan 0.00872 %, n-butyl mercaptan 0.00396%, sulfur dioxide 0.01381%, ammonium sulfide 0.00233%, n-pentyl mercaptan 0.00253%, dimethyl disulfide 0.00031%, water 4.5%, rectification tower packing is wire mesh corrugated structured packing, T1 40 theoretical plates of partition extractive distillation tower, decompression operation, operating pressure -0.05Mpa, left rectification section reflux ratio 8, right rectification section reflux ratio 3, T2 extraction agent regeneration tower decompression operation, operating pressure -0.05 Mpa, reflux ratio 3. The fe...

Embodiment 2

[0043] A device and method for desulfurization of a low-temperature methanol washing cycle methanol partition extraction rectification tower, specifically as follows:

[0044] The overall process is the same as in Example 1, but the difference is that the sulfur-rich methanol comes from the reflux section of the low-temperature methanol washing, and the contents of various sulfides are respectively carbonyl sulfide 0.02704% (wt%), hydrogen sulfide 1.57721%, methyl sulfide Alcohol 0.03598%, ethanethiol 0.06514%, n-propylene mercaptan 0.10318%, n-butanethiol 0.06474%, sulfur dioxide 0.20352%, vulcanization 0.01132%, n-pentyl mercaptan 0.0273%, dimethyl disulfide 0.04755%, methanol content Be 97.83702%, T1, T2 theoretical number of plates and operating pressure are all identical with embodiment 1, T1 left rectifying section reflux ratio 10, right rectifying section reflux ratio 4, T2 reflux ratio 4, the feeding amount of reflux methanol is 50kg / h, the amount of extractant feed i...

Embodiment 3

[0046] A device and method for desulfurization of a low-temperature methanol washing cycle methanol partition extraction rectification tower, specifically as follows:

[0047] The overall process is the same as in Example 1, but the difference is that the sulfur-rich methanol is taken from the reflux section and the prewash section of the low-temperature methanol wash at the same time, the flow rates are respectively 30kg / h and 50kg / h, and the contents of various sulfides are respectively Methanol 96.40553% (wt%), carbonyl sulfide 0.00326%, hydrogen sulfide 0.063%, methyl mercaptan 0.0061%, ethanethiol 0.033%, n-propanethiol 0.016%, n-butanthiol 0.00687%, sulfur dioxide 0.0781%, ammonium sulfide 0.00763%, n-pentyl mercaptan 0.00793%, dimethyl disulfide 0.00131%, water 3.5%, methanol content is 96.2768%, T1, T2 theoretical plate number and operating pressure are all the same as Example 1, T1 reflux ratio 10, The reflux ratio of the left rectification section of T2 is 2, the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com