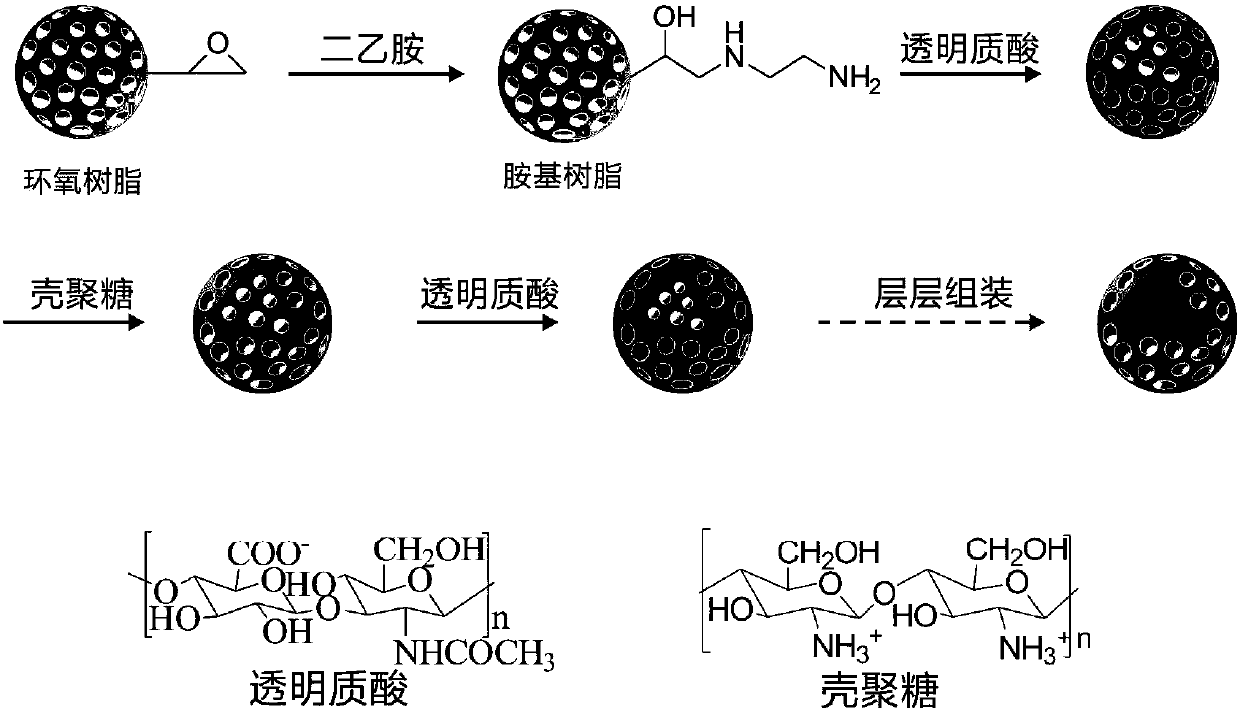

Method for preparing hydrophilic resin through multilayer self-assembly method

A self-assembly method and hydrophilic resin technology, which are applied in the preparation methods of peptides, chemical instruments and methods, coatings, etc., can solve the problem of strong heterogeneity of glycosylation sites, low glycopeptide content, and unsatisfactory analysis results. and other problems, to achieve the effect of less leakage, low preparation cost and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Preparation of porous epoxy resin

[0017] Prepare 1 L of an aqueous solution containing 10 g / L of polyvinyl alcohol and 20 g / L of gelatin as the aqueous phase solution of the epoxy resin reaction system prepared by suspension polymerization. Dissolve 120 mg of benzoyl peroxide in a mixed solution containing 12 mL of glycidyl methacrylate, 3 mL of trimethylolpropane trimethacrylate and 18 mL of n-heptane, and add the oily mixed solution to 60 mL of the aqueous phase solution In the process, the obtained oil-water two-phase layered mixed system was stirred at room temperature with a mechanical stirring speed of 300r.p.m. for 1 hour, then the temperature was raised to 80°C, and the polymerization reaction was carried out for 20 hours, and the obtained product epoxy resin was used successively After washing with acetone and ethanol three times, vacuum-dry at 60°C for 12 hours before use.

[0018] (2) Preparation of multilayer self-assembled hydrophilic resin

[0019]...

Embodiment 2

[0023] (1) Preparation of porous epoxy resin

[0024] Prepare 1 L of an aqueous solution containing 10 g / L of polyvinyl alcohol and 20 g / L of gelatin as the aqueous phase solution of the epoxy resin reaction system prepared by suspension polymerization. Dissolve 120 mg of benzoyl peroxide in a mixed solution containing 12 mL of glycidyl methacrylate, 3 mL of trimethylolpropane trimethacrylate and 18 mL of n-heptane, and add the oily mixed solution to 60 mL of the aqueous phase solution In the process, the obtained oil-water two-phase layered mixed system was stirred at room temperature with a mechanical stirring speed of 300r.p.m. for 1 hour, then the temperature was raised to 80°C, and the polymerization reaction was carried out for 20 hours, and the obtained product epoxy resin was used successively After washing with acetone and ethanol three times, vacuum-dry at 60°C for 12 hours before use.

[0025] (2) Preparation of multilayer self-assembled hydrophilic resin

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com