Agricultural plastic mulching film for controlling alternaria brassicicola of vegetables and preparation method thereof

A technology of black spot bacteria and plastic mulch, which is applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of easy leakage of dyes from the surface of the film, turbid color, and uneven dispersion, so as to promote uniform dispersion and avoid Exudation, enhanced protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

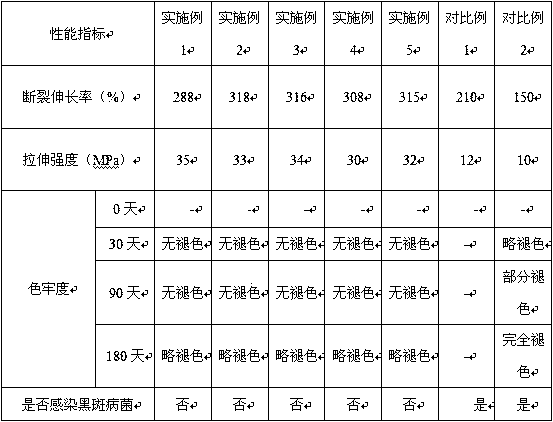

Examples

Embodiment 1

[0033] The steps of the agricultural plastic mulch film for preventing and controlling vegetable black spot bacteria prepared by the present invention are as follows:

[0034] a. Take plant stalks, air-dry them, then peel them, grind them, and sieve them to prepare materials. Add a mixed solution of peracetic acid and glacial acetic acid with a concentration of 20% by mass percentage in the sieved corn stalk cobs. The volume ratio of 20% peracetic acid to glacial acetic acid is 1:1, mix evenly, treat at 60°C for 36h, the mass concentration of the material after treatment is 15%, completely transfer to the 300 mesh slurry bag, use Soak and wash in ionized water until the washing water is neutral, centrifuge to remove excess water, and obtain cellulose with a dryness of 15%, and then use mechanical refining to refine the cellulose to obtain micron cellulose ;

[0035] B, add cobalt blue pigment in the micron cellulose that a step obtains, the addition of cobalt blue dye is 5% o...

Embodiment 2

[0042] The steps of the agricultural plastic mulch film for preventing and controlling vegetable black spot bacteria prepared by the present invention are as follows:

[0043] a. Take plant stalks, air-dry them, then peel them, grind them, and sieve them to prepare materials. Add a mixture of peracetic acid and glacial acetic acid with a mass percentage concentration of 30% in the sieved corn stalk cobs, wherein the mass percentage concentration is The volume ratio of 30% peracetic acid to glacial acetic acid is 2:1, mix evenly, treat at 60°C for 24 hours, the mass concentration of the material after treatment is 10%, completely transfer to 600 mesh slurry bag, use Soak and wash in ionized water until the washing water is neutral, centrifuge to remove excess water, and obtain cellulose with a dryness of 20%, and then use mechanical refining to refine the cellulose to obtain micron cellulose ;

[0044] B, add cobalt blue pigment in the micron cellulose that a step obtains, the...

Embodiment 3

[0051] The steps of the agricultural plastic mulch film for preventing and controlling vegetable black spot bacteria prepared by the present invention are as follows:

[0052] a. Take plant stalks, air-dry them, then peel them, grind them, and sieve them to prepare materials. Add a mixed solution of peracetic acid and glacial acetic acid with a mass percentage concentration of 25% in the sieved corn stalk cobs, wherein the mass percentage concentration is The volume ratio of 25% peracetic acid to glacial acetic acid is 1.5:1, mix evenly, treat at 60°C for 28h, the mass concentration of the material after treatment is 10%, completely transfer to 500 mesh slurry bag, use Soak and wash in ionized water until the washing water is neutral, centrifuge to remove excess water, and obtain cellulose with a dryness of 18%, and then use mechanical refining to refine the cellulose to obtain micron cellulose ;

[0053] B, add cobalt blue pigment in the micron cellulose that a step obtains,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com