A high-sensitivity up-conversion fluorescent temperature probe material and its preparation method

A fluorescent temperature and high-sensitivity technology, which is applied in the direction of luminescent materials, material analysis and material analysis through optical means, can solve the problems of low sensitivity and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A high-sensitivity up-conversion fluorescent temperature probe material with a molecular formula of Yb / Tm / Sr:NaGd(MoO 4 ) 2 .

[0022] The preparation method of the high-sensitivity up-conversion fluorescent temperature probe material comprises the following steps: (1) adding 0.695 mmol of gadolinium nitrate, 0.2 mmol of ytterbium nitrate, 0.005 mmol of thulium nitrate, 0.1 mmol of strontium nitrate, and 1 mmol of sodium carbonate Added into 8 ml of deionized water, stirred for 30 minutes to obtain a transparent solution A; (2) then 0.3 mmol of ammonium molybdate was added to the transparent solution A, and stirred for 30 minutes; (3) kept at a temperature of 100 ° C for 2 hours to obtain Dry gel; (4) Grind the dry gel for 30 minutes, then place it in a muffle furnace, keep it warm at 800° C. for 4 hours, and obtain the final product after cooling with the furnace.

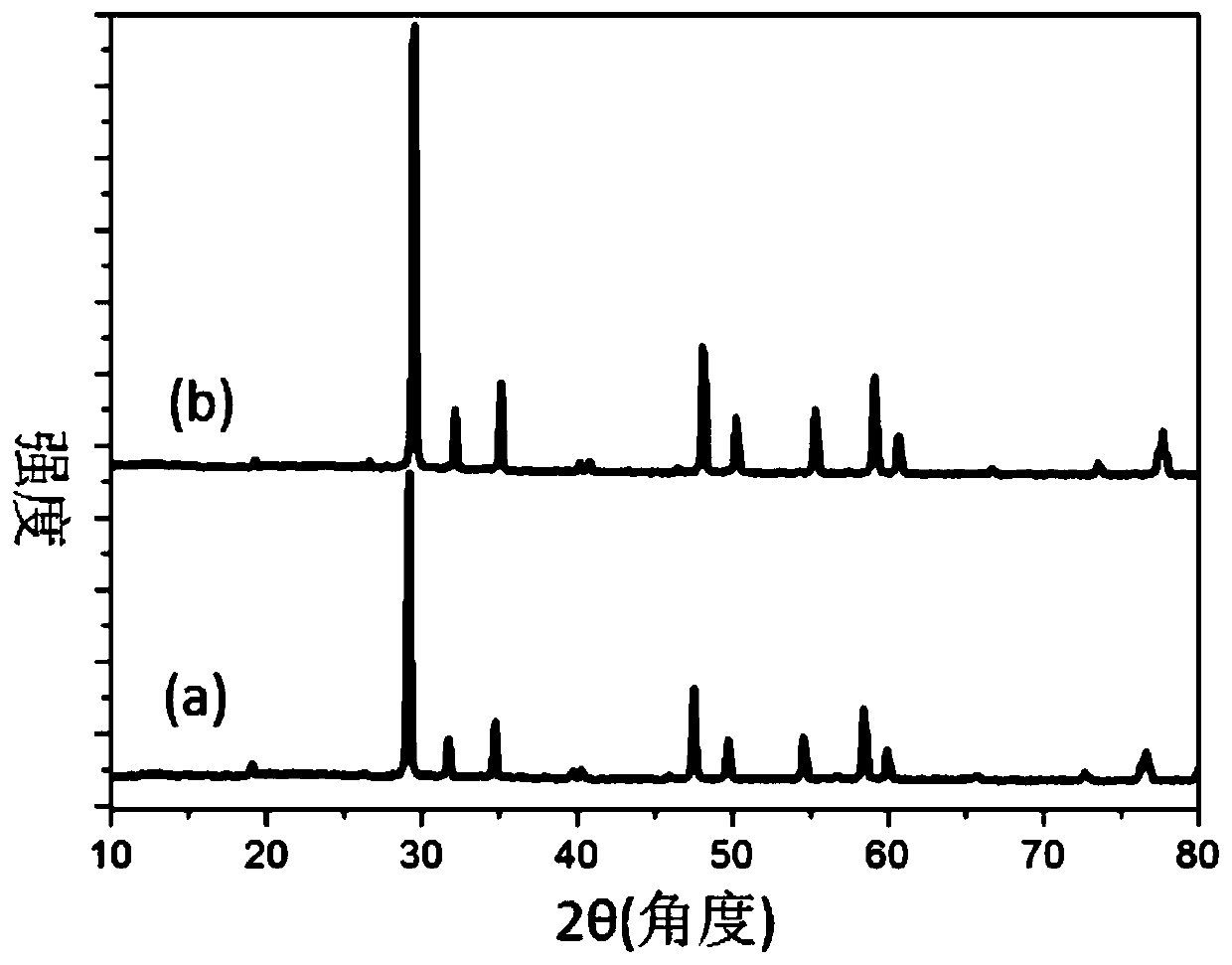

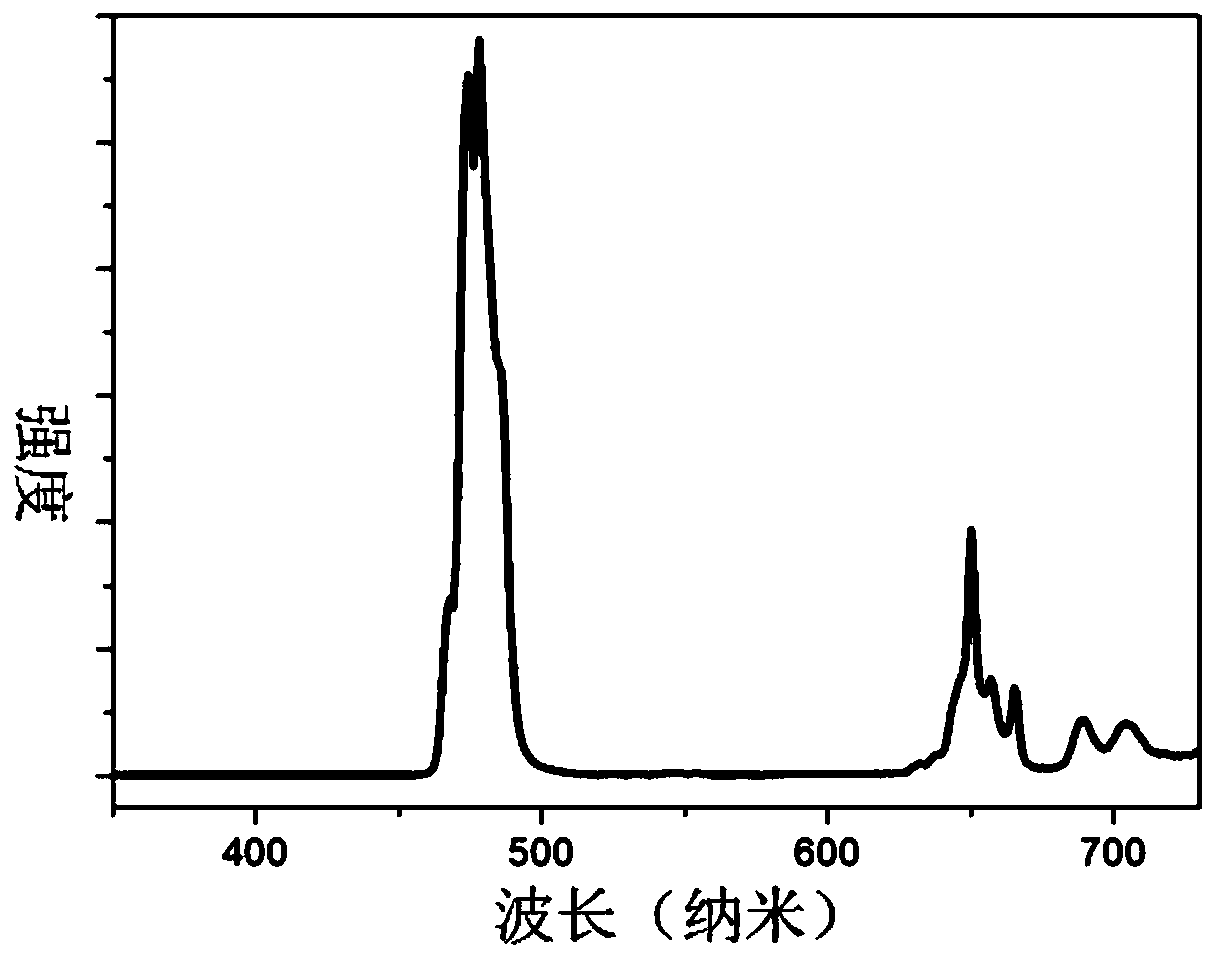

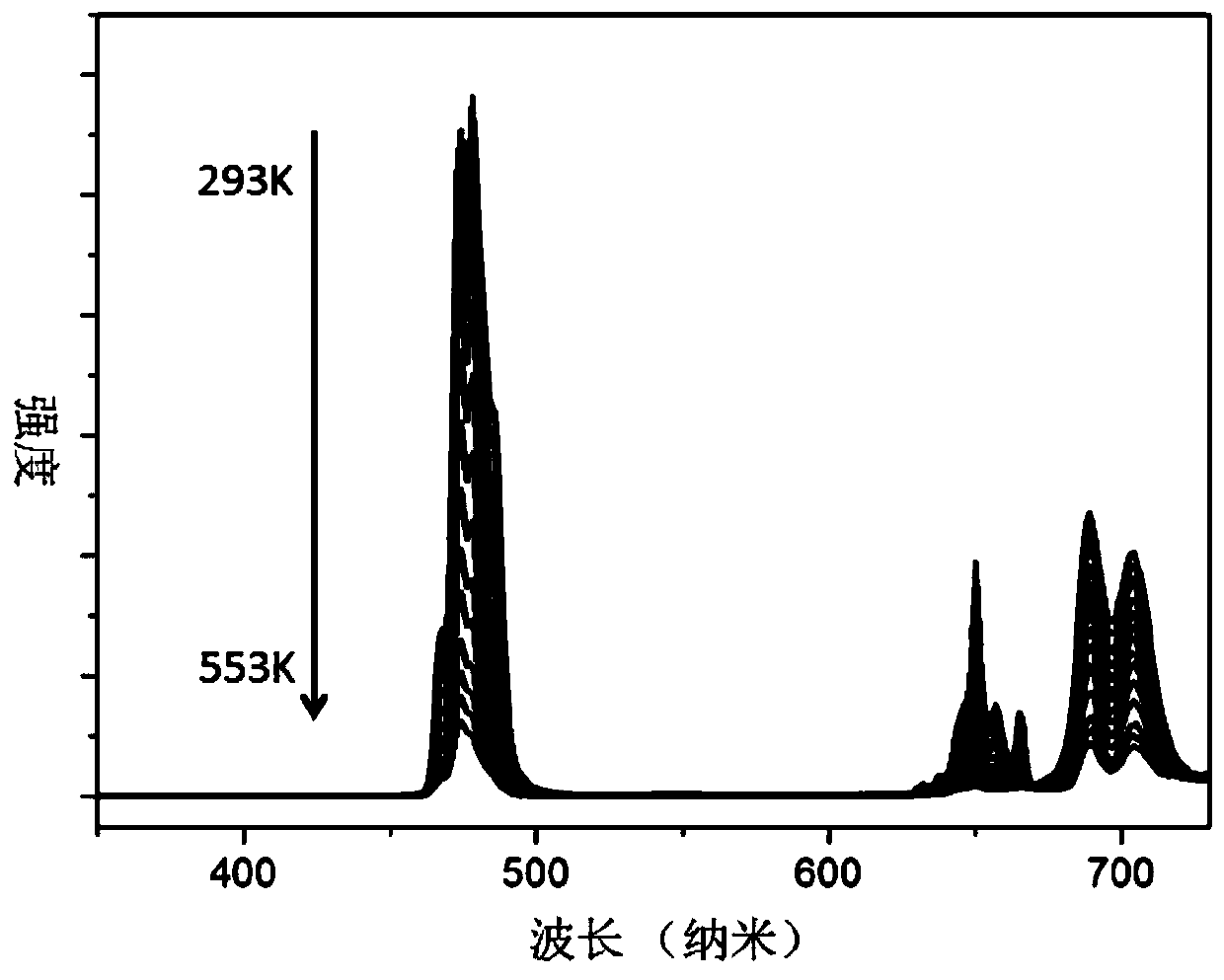

[0023] Such as figure 1 As shown in a, powder X-ray diffraction analysis shows that the obtained prod...

Embodiment 2

[0025] A high-sensitivity up-conversion fluorescent temperature probe material with a molecular formula of Yb / Tm / Sr:NaGd(MoO 4 ) 2 .

[0026] The preparation method of the high-sensitivity up-conversion fluorescent temperature probe material comprises the following steps: (1) adding 0.295 mmol of gadolinium nitrate, 0.6 mmol of ytterbium nitrate, 0.005 mmol of thulium nitrate, 0.1 mmol of strontium nitrate, and 1 mmol of sodium carbonate Added into 8 ml of deionized water, stirred for 30 minutes to obtain a transparent solution A; (2) then 0.3 mmol of ammonium molybdate was added to the transparent solution A, and stirred for 30 minutes; (3) kept at a temperature of 100 ° C for 2 hours to obtain Dry gel; (4) Grind the dry gel for 30 minutes, then place it in a muffle furnace, keep it warm at 800° C. for 4 hours, and obtain the final product after cooling with the furnace.

[0027] Such as figure 1 As shown in b, powder X-ray diffraction analysis shows that the obtained prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com