A kind of negative pole active material and preparation method thereof, negative pole material, negative pole and lithium ion battery

A negative electrode active material, negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

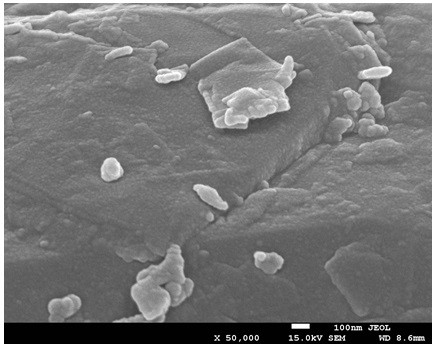

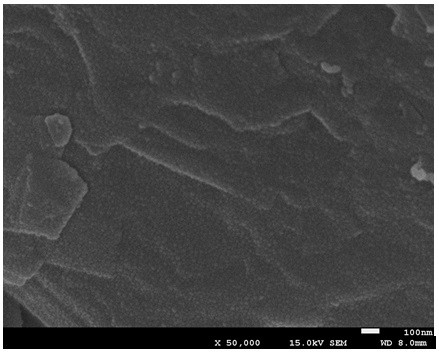

Image

Examples

preparation example Construction

[0032] The present invention also proposes a preparation method of negative electrode active material, comprising:

[0033] (1) adding graphite and isopropyl (dodecylbenzenesulfonyl) titanate into the first organic solvent according to the ratio, stirring under sealed conditions and drying to obtain a solid;

[0034] (2) Mix the solid in step (1) with the second organic solvent and water according to the proportion, stir and dry to obtain the negative electrode active material.

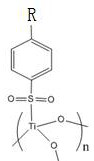

[0035] In the present invention, the isopropyl (dodecylbenzenesulfonyl) titanate has a structural formula shown in formula (3):

[0036]

[0037] Formula (3).

[0038] In step (1), graphite and isopropyl (dodecylbenzenesulfonyl) titanate are added in the first organic solvent according to the proportion and the purpose of stirring under sealed conditions is to prevent the isopropyl (dodecylbenzenesulfonyl) titanate from Sulfonyl) titanate is lost due to hydrolysis before adsorption is formed on t...

Embodiment 1

[0057] (1) Prepare the precursor of isopropyl (dodecylbenzenesulfonyl) titanate adsorbed on the surface of graphite particles

[0058] Take 10g of graphite (the particle size of graphite particles meets D50=10um) and add it to 30ml of ethanol solution (after dehydration treatment, water content is 2.8%) and stir for one minute, slowly add 0.2g of triisopropyl (dodecyl Benzenesulfonyl) titanate, stirred for 1 h under sealed conditions, filtered, and the graphite on the filter paper was cleaned with absolute ethanol, and then dried in a decompression oven at low pressure (10kpa);

[0059] (2) Preparation of negative electrode active material

[0060] The above precursor was added to a mixed solution of 20ml ethanol and 10ml water, stirred at 50°C for 1h, filtered and washed, then dried at 110°C to obtain the negative electrode active material A1 described in this application.

[0061] (3) Preparation of lithium ion battery

[0062] The negative electrode active material A1, ac...

Embodiment 2

[0064] The same steps and methods as in Example 1 are used to prepare the battery, the difference is that 10 g of graphite is added in step (1), the particle size of the graphite particles satisfies D50=12um, and isopropyl (dodecylbenzenesulfonyl) titanium is added Ester 0.8g; Negative electrode active material A2 and lithium ion battery S2 were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com