Preparation method of ferrocerium heterogeneous composite activated carbon fiber

A technology of activated carbon fiber and ferric cerium, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of environmental pollution and high energy consumption of raw materials, and achieves low environmental pollution, simple method and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

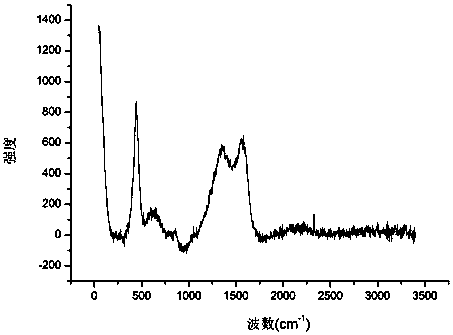

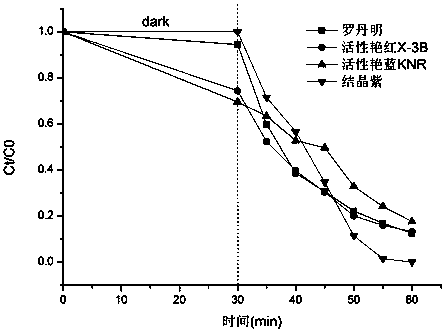

Embodiment 1

[0026] Prepare cerium nitrate and ferric chloride solutions separately, so that the molar ratio of cerium element and iron element is 1:1, mix the two solutions, take 50ml of the mixed solution of cerium nitrate and ferric chloride, add 2mmol / L hydration After the citric acid was placed on a magnetic stirrer and stirred, ammonia water was added dropwise to adjust the pH of the mixture to 2.18 to prepare a brownish yellow gel. Crush the waste cotton fabric into short lints of about 2 cm, take 0.8 g of short lints and add them to the gel for soaking for 48 hours, stirring slowly during the soaking process. After the impregnated short cotton wool is dried in a drying oven at 60°C, place it in an aluminum crucible for calcination, raise the temperature to 450°C at a calcination rate of 5°C / min, keep it warm for 30 minutes, and take it out after cooling to obtain ferrocerium isocyanide Composite activated carbon fiber samples. Take 0.03g cerium-iron composite activated carbon fibe...

Embodiment 2

[0028] Prepare cerium nitrate and ferric chloride solutions separately, so that the molar ratio of cerium element and iron element is 3:1, mix the two solutions, take 50ml of the mixed solution of cerium nitrate and ferric chloride, add 4mmol / L hydration After the citric acid was placed on a magnetic stirrer and stirred, ammonia water was added dropwise to adjust the pH of the mixture to 7.613 to prepare a brown yellow gel. Crush waste cotton fabrics into short lints of about 2 cm, take 1 g of short lints and add them to the gel for soaking for 72 hours, stirring slowly during the soaking process. The impregnated short cotton wool is dried in a drying oven at a low temperature of 50 degrees, and then placed in an aluminum crucible for calcination. The temperature is raised to 350 degrees at a calcination rate of 5 ℃ / min, and then kept for 30 minutes. After cooling, it is taken out to obtain ferrocerium Composite activated carbon fiber samples. The evaluation method of the pho...

Embodiment 3

[0034] Prepare cerium nitrate and ferric chloride solutions separately, so that the molar ratio of cerium element and iron element is 1:3, mix the two solutions, take 50ml of the mixed solution of cerium nitrate and ferric chloride, add 4mmol / L hydration After the citric acid was stirred on a magnetic stirrer, ammonia water was added dropwise to adjust the pH of the mixture to 0.789 to prepare a brownish yellow gel. Crush waste cotton fabrics into short lints of about 2 cm, take 1 g of short lints and add them to the gel for soaking for 54 hours, stirring slowly during the soaking process. The impregnated short cotton wool is dried in a drying oven at a low temperature of 50°C, then placed in an aluminum crucible for calcination, heated to 550°C at a calcination rate of 5°C / min, and then kept for 30 minutes, then taken out after cooling to obtain ferrocerium isocyanate Composite activated carbon fiber samples. Take 0.03g cerium-iron composite activated carbon fiber sample and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com