Graphene collaborative continuous glass fiber reinforced halogen-free flame-retardant weather-proof PPO/PA alloy material and preparation method thereof

A continuous glass fiber and alloy material technology, applied in the field of polymer materials, can solve problems such as poor interface compatibility, and achieve the effects of reducing viscosity, high mechanical properties, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

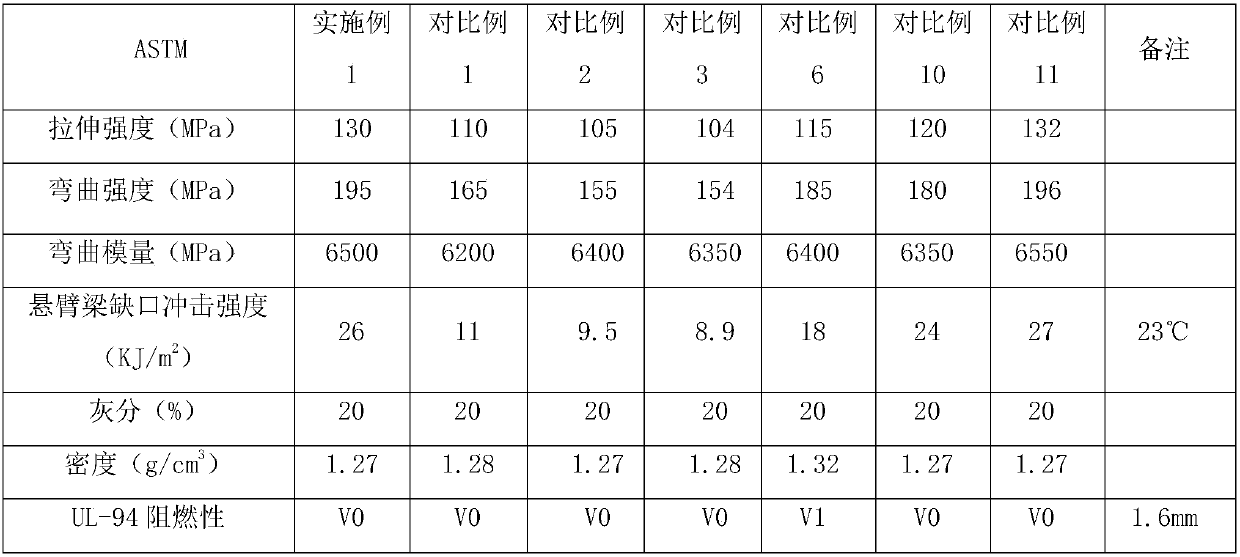

Embodiment 1

[0040] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, the cutting length of the material is 6-25mm, the particle size is 4.0mm, and it includes the following components by weight: PPO 480 320 parts of PA6, 200 parts of continuous glass fiber, 5 parts of graphene, 10 parts of compatibilizer, 80 parts of toughening agent, 80 parts of flame retardant, 6 parts of antioxidant, 5 parts of compound light stabilizer, lubrication Agent PETS 6 parts, zinc oxide 5 parts;

[0041] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, comprising the following steps:

[0042] a. Drying preparation: the preheating and drying conditions of PPO are dried at 100-110°C for 3-4 hours, and the preheated drying conditions of PA6 are dried at 80-100°C for 4-6 hours;

[0043] B, mixing preparation: 5 parts of g...

Embodiment 2

[0054] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, the cutting length of the material is 6-25mm, the particle size is 4.0mm, and it includes the following components by weight: PPO 420 280 parts of PA6, 300 parts of continuous glass fiber, 10 parts of graphene, 15 parts of compatibilizer, 65 parts of toughening agent, 100 parts of flame retardant, 8 parts of antioxidant, 4 parts of compound light stabilizer, lubricating Agent A-C540A 6 parts, calcium oxide 10 parts;

[0055] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, comprising the following steps:

[0056] a. Drying preparation: the preheating and drying condition of PPO is 3-4 hours at 100-110°C, and the preheating and drying condition of PA is 4-6 hours at 80-100°C;

[0057] B, mixing preparation: 10 parts of graphene, g...

Embodiment 3

[0065] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, the material has a cutting length of 6-25mm and a particle size of 3.0mm, including the following components by weight: PPO:360 Parts, PA6: 240 parts, continuous glass fiber: 400 parts, graphene 15 parts, compatibilizer 20 parts, toughening agent 50 parts, flame retardant 120 parts, antioxidant: 10 parts, compound light stabilizer: 3 parts, lubricant GM-100: 8 parts, zinc oxide 15 parts;

[0066] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / PA alloy material, comprising the following steps:

[0067] a. Drying preparation: the preheating and drying conditions of PPO are dried at 100-110°C for 3-4 hours, and the preheated drying conditions of PA6 are dried at 80-100°C for 4-6 hours;

[0068] B, mixing preparation: 15 parts of graphene and graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com