Difunctional electrolyte applicable to embedded and conversion type lithium battery, preparation method, and lithium battery comprising electrolyte

An electrolyte and lithium battery technology, applied in lithium storage batteries, secondary batteries, organic electrolytes, etc., can solve the problems of low flash point, poor oxidation resistance and low flash point of ether electrolytes, and improve high temperature performance and safety. properties, good flame retardant effect, high energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

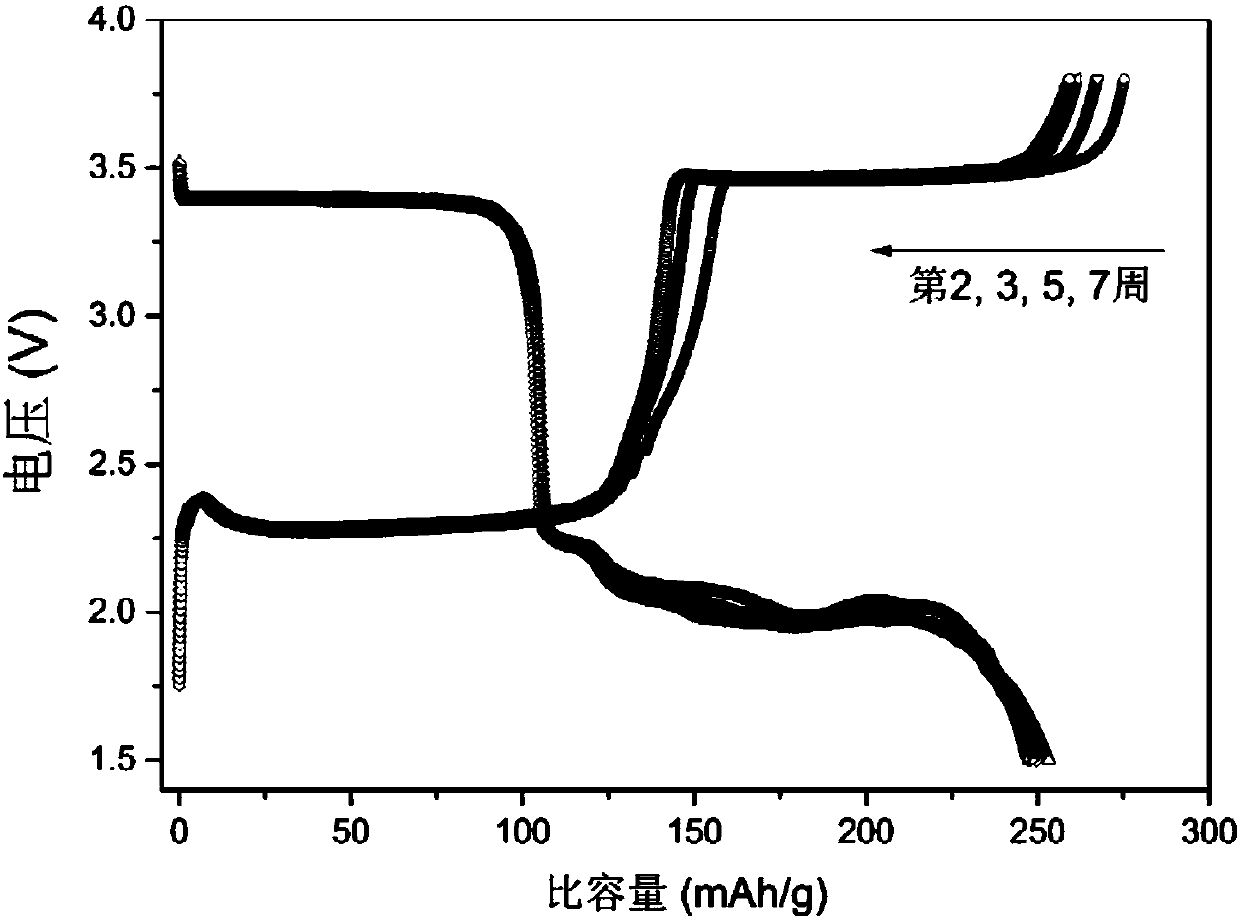

Image

Examples

Embodiment 1

[0033] Lithium battery electrolyte 1, composed of polyether ionic liquid [G3Li + ][TFSI - ] dispersed in a fluoroether solvent bis(1,1,2,2)-tetrafluoroethyl ether, and the content of the ionic liquid is 25% (mass fraction).

[0034] Its preparation steps are as follows:

[0035] 1) Preparation of polyether ionic liquid:

[0036]In a dry atmosphere at room temperature (dew point below -40°C), slowly add lithium bistrifluoromethanesulfonyl imide (LiTFSI) into triethylene glycol dimethyl ether (G3) with an equimolar water content below 30ppm, and stir More than 2 hours until the mixture is homogeneous and there is no phase separation, the product [G3Li + ][TFSI - ].

[0037] 2) Preparation of ionic liquid electrolyte:

[0038] A part (mass ratio) of the ionic liquid prepared in the previous step is dispersed in three parts of bis(1,1,2,2)-tetrafluoroethyl ether with a water content below 20ppm, and the content of the ionic liquid obtained after mixing is 25% (mass fraction...

Embodiment 2

[0040] Lithium battery electrolyte 2, composed of polyether ionic liquid [G3Li + ][TFSI - ] dispersed in fluoroether solvent bis(1,1,2,2)-tetrafluoroethyl ether, the content of ionic liquid is 90% (mass fraction).

[0041] The preparation process of the ionic liquid was the same as in Example 1, but the mass fraction of the solvent was reduced to 10% in the preparation of the electrolyte. Electrolyte 2 is obtained after mixing evenly.

Embodiment 3

[0043] Lithium battery electrolyte 3, composed of polyether ionic liquid [G4Li + ][TFSI - ], dispersed without solvent.

[0044] The preparation process of the ionic liquid is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com