A micro-energy harvester based on piezoelectric thick film mems technology and its preparation method

A micro-energy, harvester technology, used in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. It can solve the problems of poor piezoelectric performance and simple design structure of piezoelectric films, and achieve the effects of diverse and complex device structures, high preparation efficiency and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

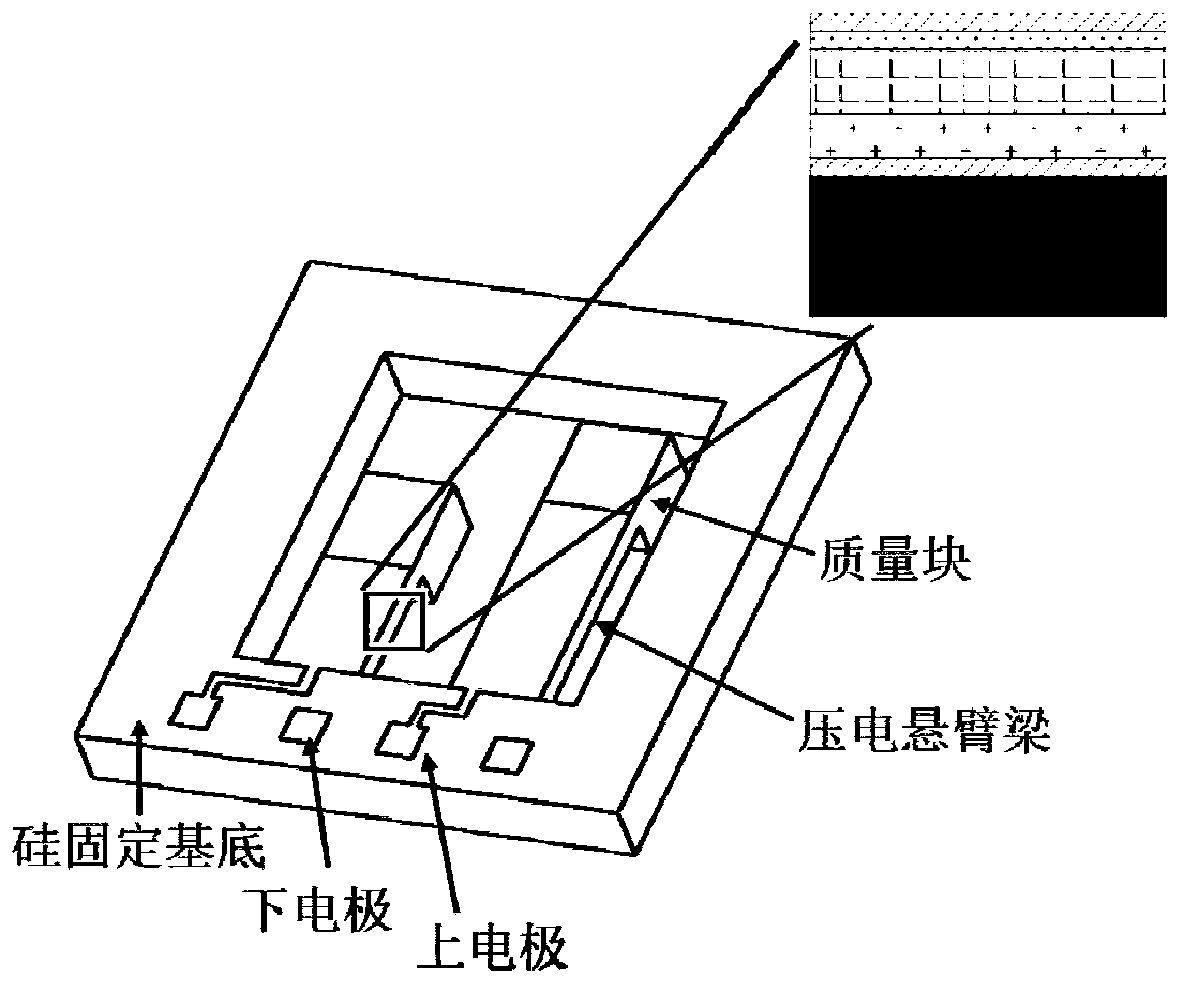

[0038] figure 1 It is a three-dimensional structure diagram of a micro-energy harvester, including: an upper electrode, a lower electrode, a silicon fixed base, a piezoelectric cantilever beam, and a quality block fixedly connected to one end of the piezoelectric cantilever beam and suspended in the air. Wherein, one end of the piezoelectric cantilever beam is fixedly connected to the inner side wall of the silicon fixed base, and extends toward the inner side wall on the other side opposite to the inner side wall. The other end of the piezoelectric cantilever is fixedly connected to the suspended mass. The upper electrode and the lower electrode are formed on a silicon fixed base, and the upper electrode covers the piezoelectric cantilever arm.

[0039]Among them, the piezoelectric cantilever beam is a multi-layer structure prepared by bonding and coating a silicon chip and a piezoelectric ceramic chip. From bottom to top, it is as follows: a Si layer with a thickness of 150...

Embodiment 2

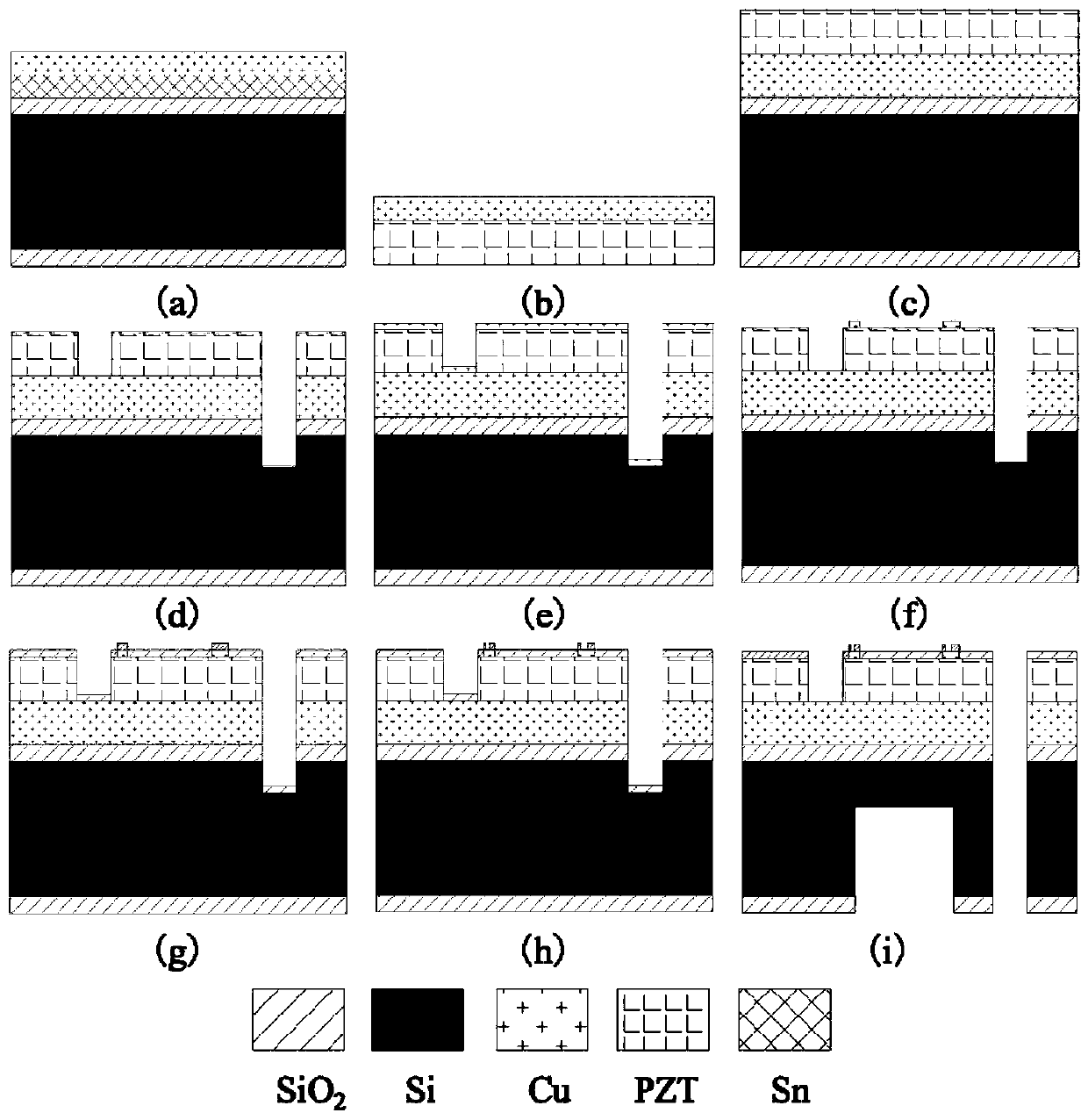

[0042] figure 2 It is the MEMS process flow chart of the entire device preparation. The process mainly includes the production of metal electrodes, the bonding of PZT piezoelectric ceramics and the substrate, the piezoelectric thick film process, the device patterning process and the release process of the cantilever beam. Fabrication of Micro Energy Harvester Based on Piezoelectric Thick Film MEMS Technology. Specific process flow:

[0043] (a) Electroplating 6um thick Cu and 6.5um thick Sn on a 4-inch silicon dioxide wafer (500um thick silicon in the middle, 500nm silicon dioxide on both sides) as a bonding layer and also a lower electrode layer;

[0044] (b) Plating Cu with a thickness of 6.5um on a 4-inch piezoelectric ceramic sheet as a bonding layer and also a lower electrode layer;

[0045] (c) Carry out eutectic bonding of the piezoelectric ceramic sheet and the silicon dioxide sheet that have been electroplated, and then mechanically thin, grind and polish the bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com