Transparent ultra-wideband microwave absorber based on transparent conductive film

A transparent conductive film, ultra-broadband technology, applied in electrical components, antennas, etc., can solve the problems of limiting the development of stealth microwave systems, poor absorbing performance, large size, etc., and achieve the effect of excellent absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

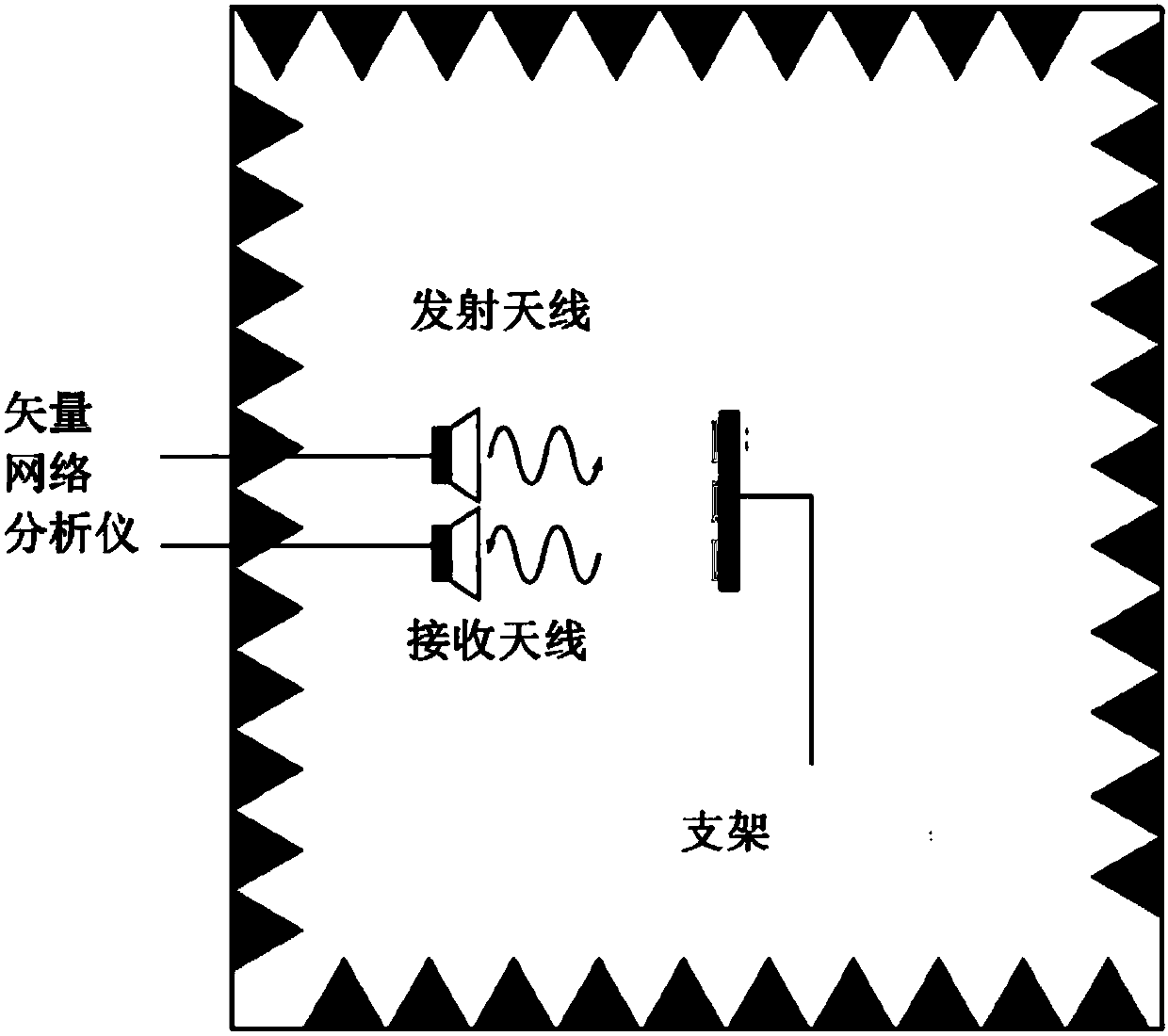

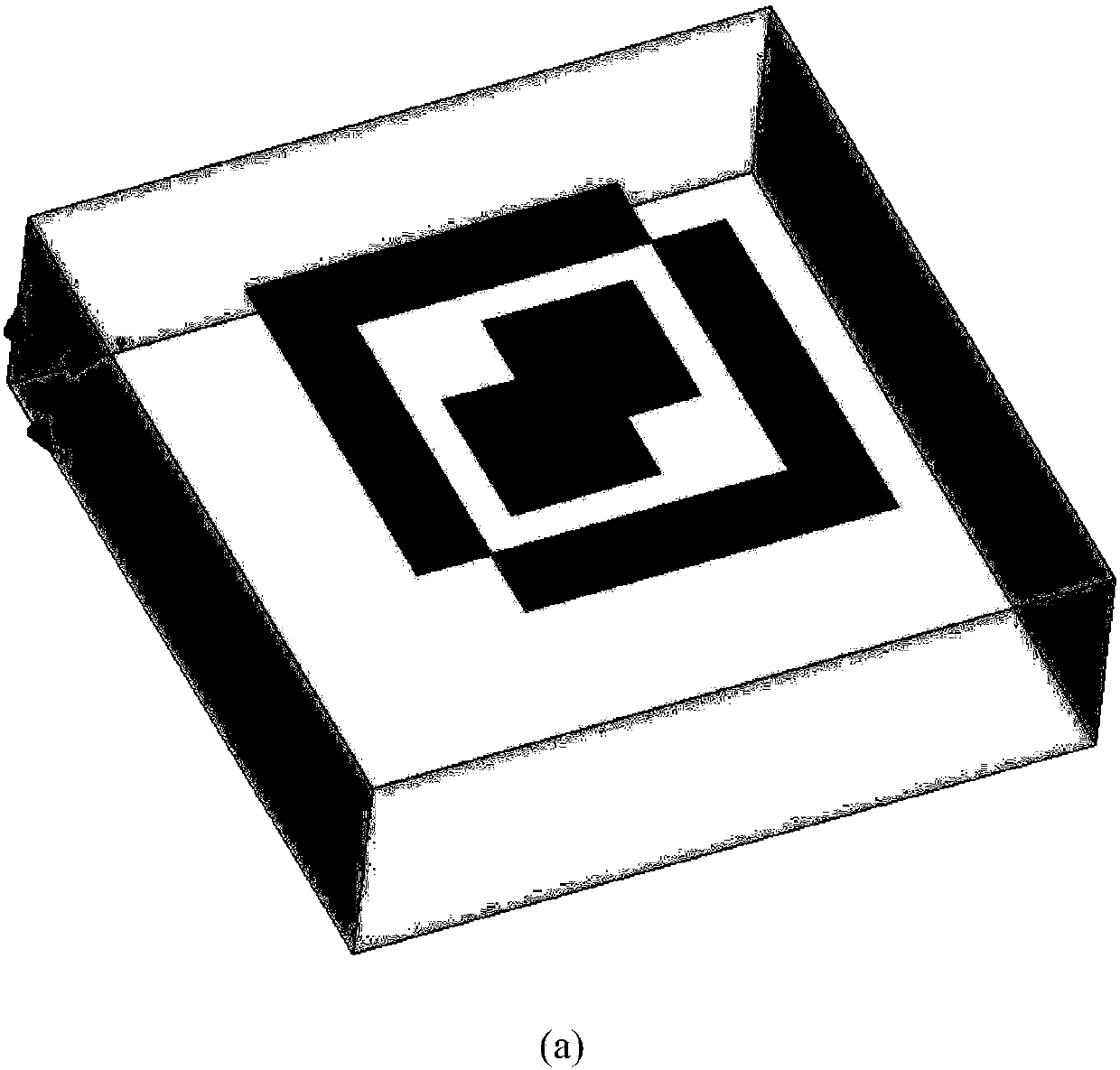

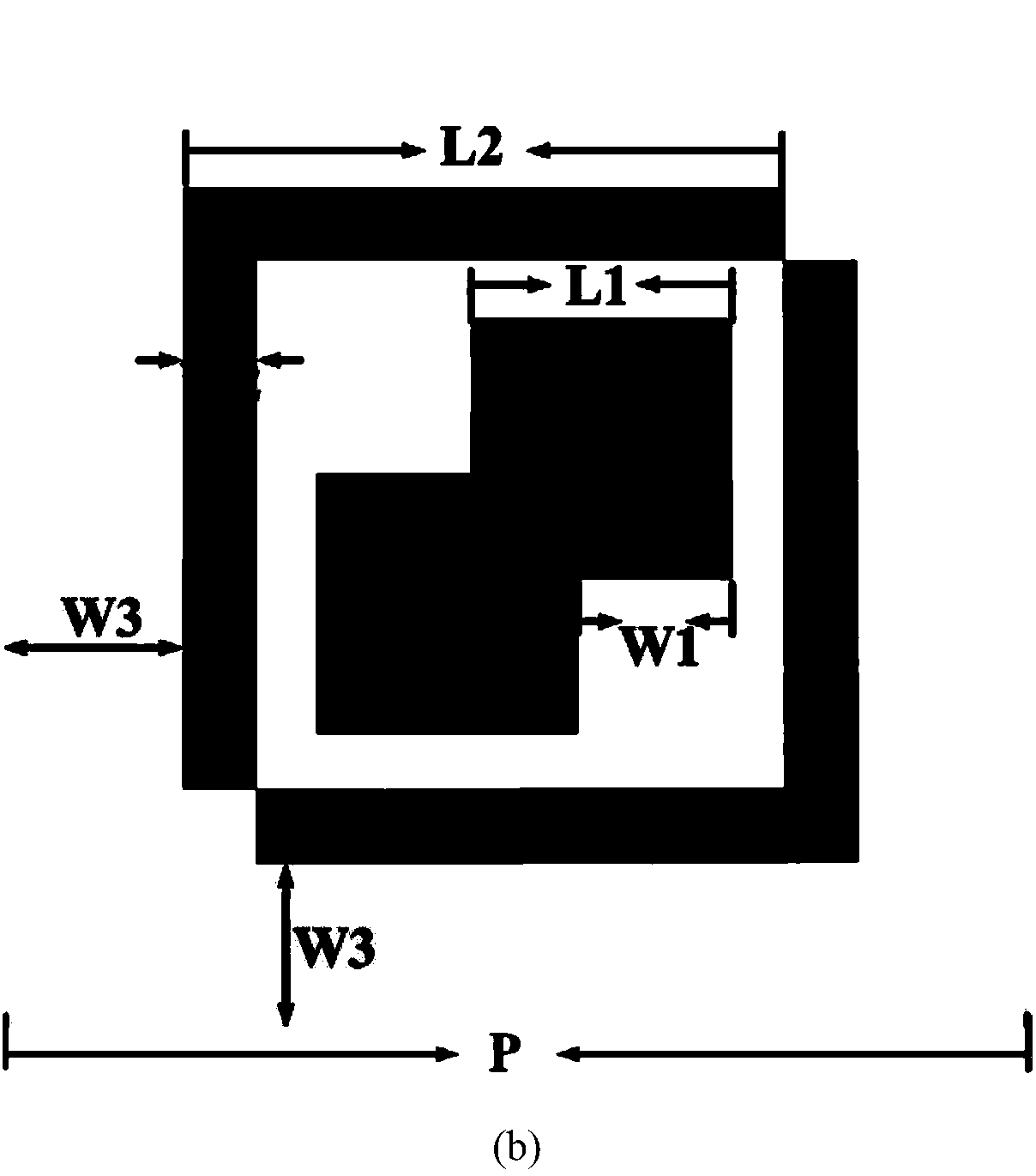

[0019] A transparent ultra-broadband microwave absorber based on a transparent conductive film, including glass and indium tin oxide film coated on both sides of the glass. The thickness of the microwave absorber is 1.1mm, and the film corresponding to the microwave incident surface is etched with a periodic structure. . A unit structure in a periodic structure such as figure 2 As shown, it consists of two overlapping squares. The side length of the square is 800um, and the overlapping part is 400um. The rectangular open ring surrounded by the outside has a side length of 2000um and a width of 400um. The size of the sample is 9.6mm*9.6mm, which contains a total of 576 unit structures in the above-mentioned 24 rows*24 columns. Under the electromagnetic wave of the frequency to be absorbed, the impedance of the absorbing structure and the impedance of the electromagnetic wave in free space achieve impedance matching.

[0020] image 3 for use figure 2 The comparison chart o...

Embodiment 2

[0025] Example 2 A series of experiments were carried out on the combined design of the center position of the wave-absorbing structural unit and the materials of the substrate and the conductive film. Side triangle, parallelogram, rectangle, square, cross or stripe structure, transparent conductive film includes indium tin oxide ITO, fluorine doped tin oxide FTO, zinc tin oxide ZTO, aluminum doped zinc oxide AZO, gallium tin oxide GTO, poly Ethylenedioxythiophene-polystyrene sulfonate PEDOT:PSS, graphene or carbon nanotube conductive film, the transparent medium is glass, polyimide PI, polyester PET, polynaphthalene and ethylene glycol ester PEN, Polyvinyl alcohol PVA, polydimethylsiloxane PDMS or polystyrene PS. In the experimental design, the specific size of the sample and each unit is adjusted. When a suitable periodic structure is selected to cooperate with the substrate and conductive film, the microwave broadband absorption effect can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com