Preparation method for preparing paraxylene catalyst by virtue of alkylation of methanol

A xylene catalyst, alkylation technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Uniformity, poor catalyst stability and other problems, to achieve the effects of high catalytic activity and stability, shortened process route, and improved single-pass yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

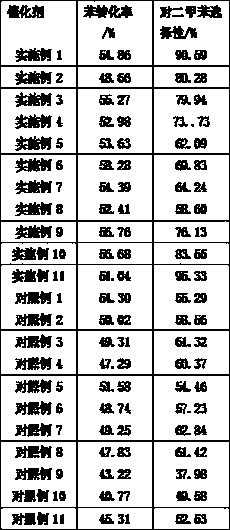

Examples

Embodiment 1

[0016] A kind of preparation method that methanol alkylation produces p-xylene catalyst, comprises the following steps:

[0017] Step 1. Pt(acac) with a total mass of 50mg 2 and Fe(acac) 2 and the precursor are put into a reaction kettle with a volume of 20ml, and the Pt(acac) 2 and Fe(acac) 2 The molar ratio of the substance is 1:1;

[0018] Step 2. Put 20g of Cu-BTC nanoporous material into the reaction kettle, then add 500μL of tetrahydrofuran into the reaction kettle, close the reaction kettle, and press into 150atm supercritical CO 2 In the reaction kettle, heat to 60°C, keep it warm for 2 hours, and then slowly release the pressure to obtain the preparation of nanoporous materials supporting Pt and Fe precursors;

[0019] Step 3, put the above precursor into the reaction kettle, add 1mL tetrahydrofuran borane, close the reaction kettle, press into 150atm supercritical CO 2 In the reaction kettle, heat to 80°C and keep it warm for 2 hours. After the reaction is over,...

Embodiment 2

[0027] Step 1. Pt(acac) with a total mass of 30mg 2 Fe(acac) 2 and the precursor are put into a reaction kettle with a volume of 20ml, and the Pt(acac) 2 Fe(acac) 2 The molar ratio of the substance is 1:1;

[0028] All the other steps are the same as in Example 1.

Embodiment 3

[0030] Step 1. Pt(acac) with a total mass of 15mg 2 Fe(acac) 2 and the precursor are put into a reaction kettle with a volume of 20ml, and the Pt(acac) 2 Fe(acac) 2 The molar ratio of the substance is 1:1;

[0031] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com