Preparation method of CDs/PVDF (Polyvinylidene Fluoride) composite thin film

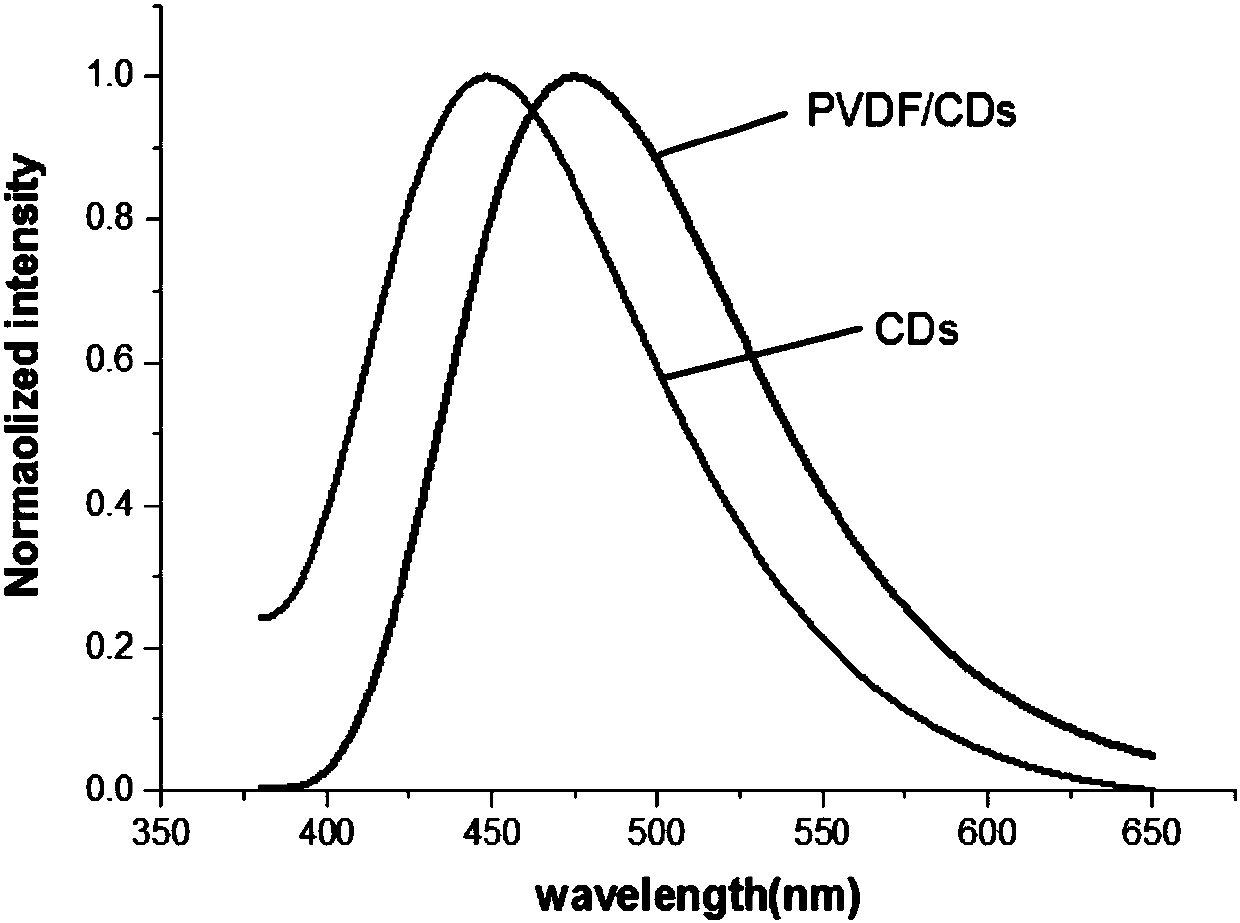

A composite film and solution technology, applied in the field of material chemistry, can solve the problems of reduced transparency of composite materials, self-quenching of carbon quantum dot fluorescence, etc., and achieves the effects of excellent fluorescence characteristics, simple operation and realization process, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

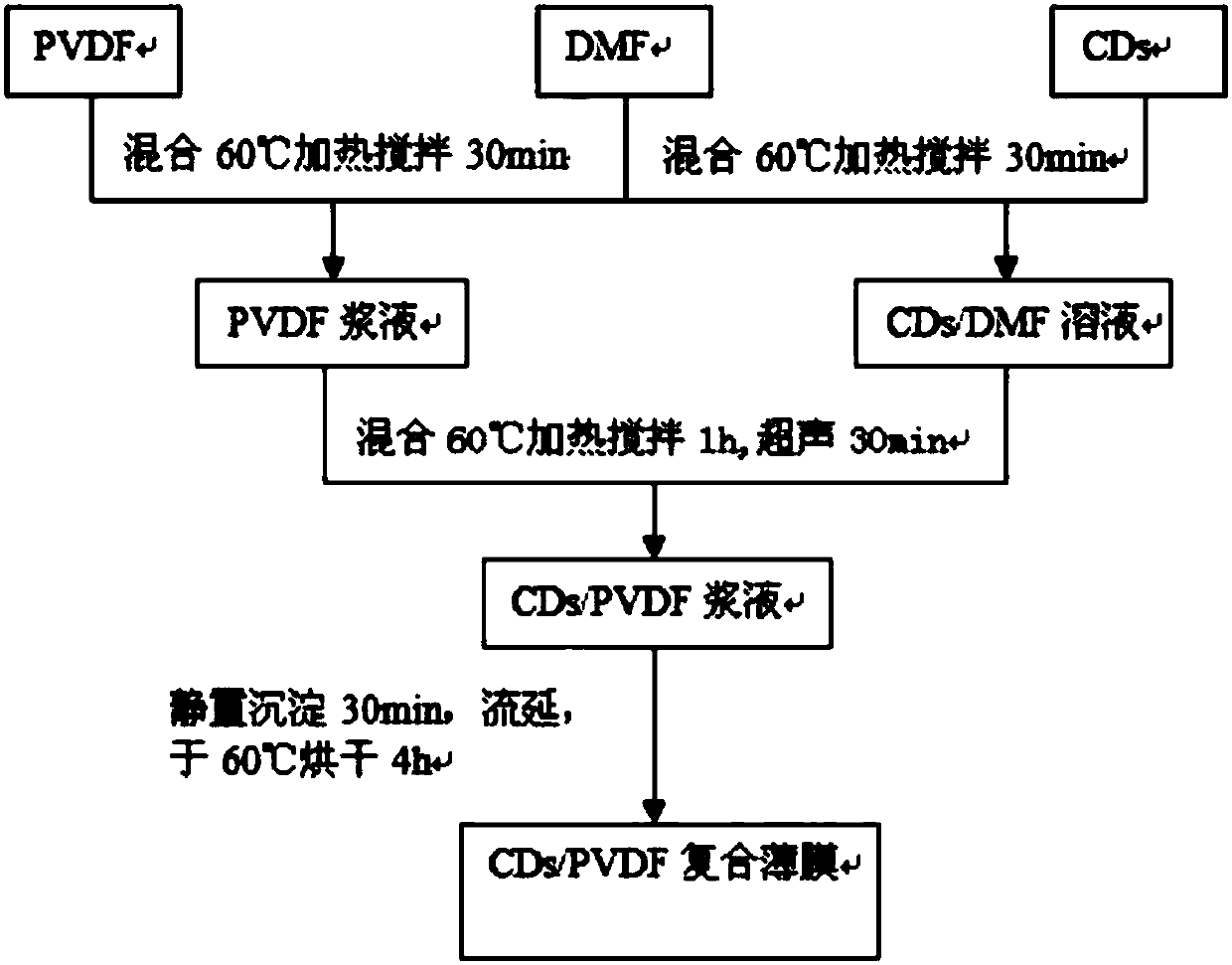

[0026] Embodiment 1 A kind of preparation method of CDs / PVDF composite film

[0027] (1) Preparation method

[0028] 1) Weigh 3.08g of citric acid and 4.63ml of diethylenetriamine, dissolve in 80ml of deionized water, stir magnetically for 30min, and then sonicate for 10min. The mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an oven, heated at 180°C for 5 hours, and cooled to room temperature with the furnace to obtain a carbon quantum dot CDs solution, which was stored in a refrigerator at 4°C for later use.

[0029] 2) Add 0.25ml CDs solution into a 100ml beaker containing 10ml DMF solution, heat to 60°C under magnetic stirring, and stir at 60°C for 30 minutes to obtain CDs / DMF solution.

[0030] 3) Weigh 3.16g of PVDF and dissolve it in 30ml of DMF, heat it in a water bath to 60°C under magnetic stirring, and stir at 60°C for 30 minutes to obtain a PVDF solution.

[0031] 4) Mix the CDs / DMF solution and the PVDF solution...

Embodiment 2

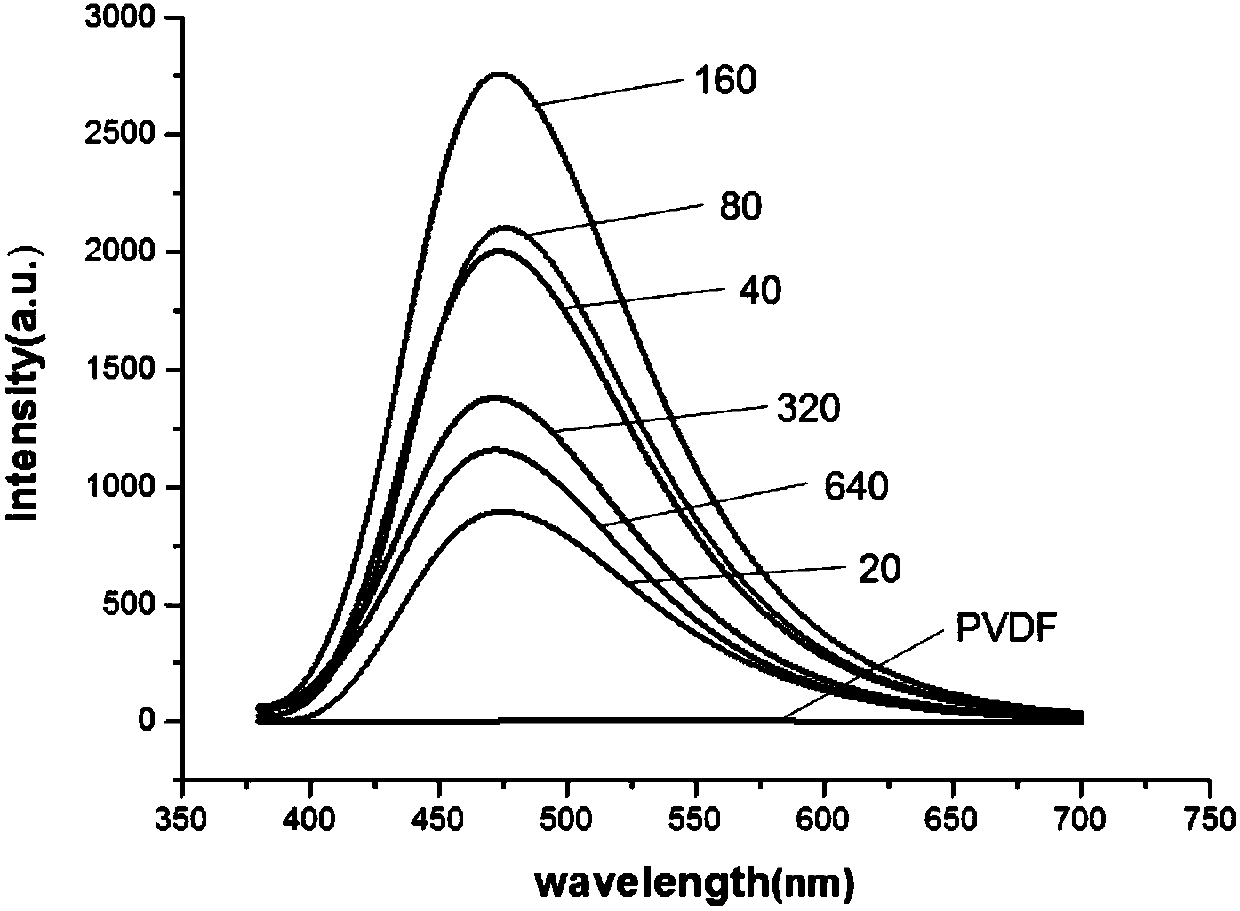

[0038] Example 2 Effect of CDs doping ratio on luminous intensity

[0039] (1) Preparation method

[0040] 1) Weigh 3.08g of citric acid and 4.63ml of diethylenetriamine, dissolve in 80ml of deionized water, stir magnetically for 30min, and then sonicate for 10min. The mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an oven, heated at 180°C for 5 hours, and cooled to room temperature with the furnace to obtain a carbon quantum dot CDs solution, which was stored in a refrigerator at 4°C for later use.

[0041] 2) Take 0.25ml of CDs solution respectively, add them into beakers containing 5ml, 10ml, 20ml, 40ml, 80ml, and 160ml of DMF solution, heat to 60°C under magnetic stirring, and stir at 60°C for 30 minutes to obtain CDs / DMF solution with a volume ratio of 1:20, 1:40, 1:80, 1:160, 1:320, 1:640.

[0042] 3) Weigh 3.16g of PVDF and dissolve it in 30ml of DMF, heat it in a water bath to 60°C under magnetic stirring, and stir ...

Embodiment 3

[0047] Example 3 Effect of PVDF mass fraction on film luminescence

[0048] (1) Preparation method

[0049] 1) Weigh 3.08g of citric acid and 4.63ml of diethylenetriamine, dissolve in 80ml of deionized water, stir magnetically for 30min, and then sonicate for 10min. The mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an oven, heated at 180°C for 5 hours, and cooled to room temperature with the furnace to obtain a carbon quantum dot CDs solution, which was stored in a refrigerator at 4°C for later use.

[0050] 2) Add 0.25ml CDs solution into a 100ml beaker containing 10ml DMF solution, heat to 60°C under magnetic stirring, and stir at 60°C for 30 minutes to obtain CDs / DMF solution.

[0051] 3) Weigh 0.525g, 0.788g and 1.05g of PVDF and dissolve them in 10ml of DMF, heat them in a water bath to 60°C under magnetic stirring, and stir at 60°C for 30 minutes to obtain PVDF content of 5wt%, respectively. 7.5wt% and 10wt% PVDF sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com