Regeneration device for copper chloride corrosion solution

A technology for regeneration device and corrosive liquid, applied in the field of copper chloride corrosive liquid regeneration device, can solve the problems of high cost input, large consumption of raw liquid, high waste liquid discharge and treatment cost, save production cost, reduce labor intensity, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

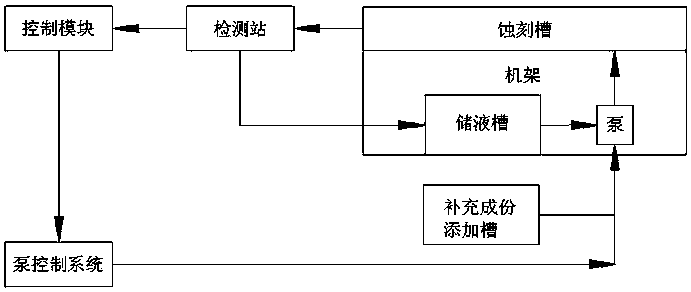

[0018] As shown in the figure, a copper chloride corrosion solution regeneration device, the copper chloride corrosion solution regeneration device of the present invention includes a frame, an etching tank is installed above the frame, and it is characterized in that: a storage tank is installed below the frame The liquid storage tank of the etching solution, the liquid storage tank is connected to the etching tank through the pump; the etching tank is connected to the liquid inlet of the detection station capable of detecting the content of the active ingredients of the etching liquid in the etching tank through a pipeline, and the liquid outlet of the detection station is connected to the storage tank through a pipeline Liquid tank; the detection station is connected with a control module capable of receiving the detection signal of the detection station through communication, and the control module is connected to the pump control system through communication, and the pump c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com