Green muscardine fungus conidium microcapsule and preparation method and application thereof

A technology of conidia and Metarhizium anisopliae, applied in the directions of microcapsule preparation, microsphere preparation, botanical equipment and method, etc., can solve the problems of poor stress resistance and short storage period, so as to overcome the poor stress resistance and prolong storage. Effect of time, significant market application and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of metarhizium anisopliae conidia microcapsules

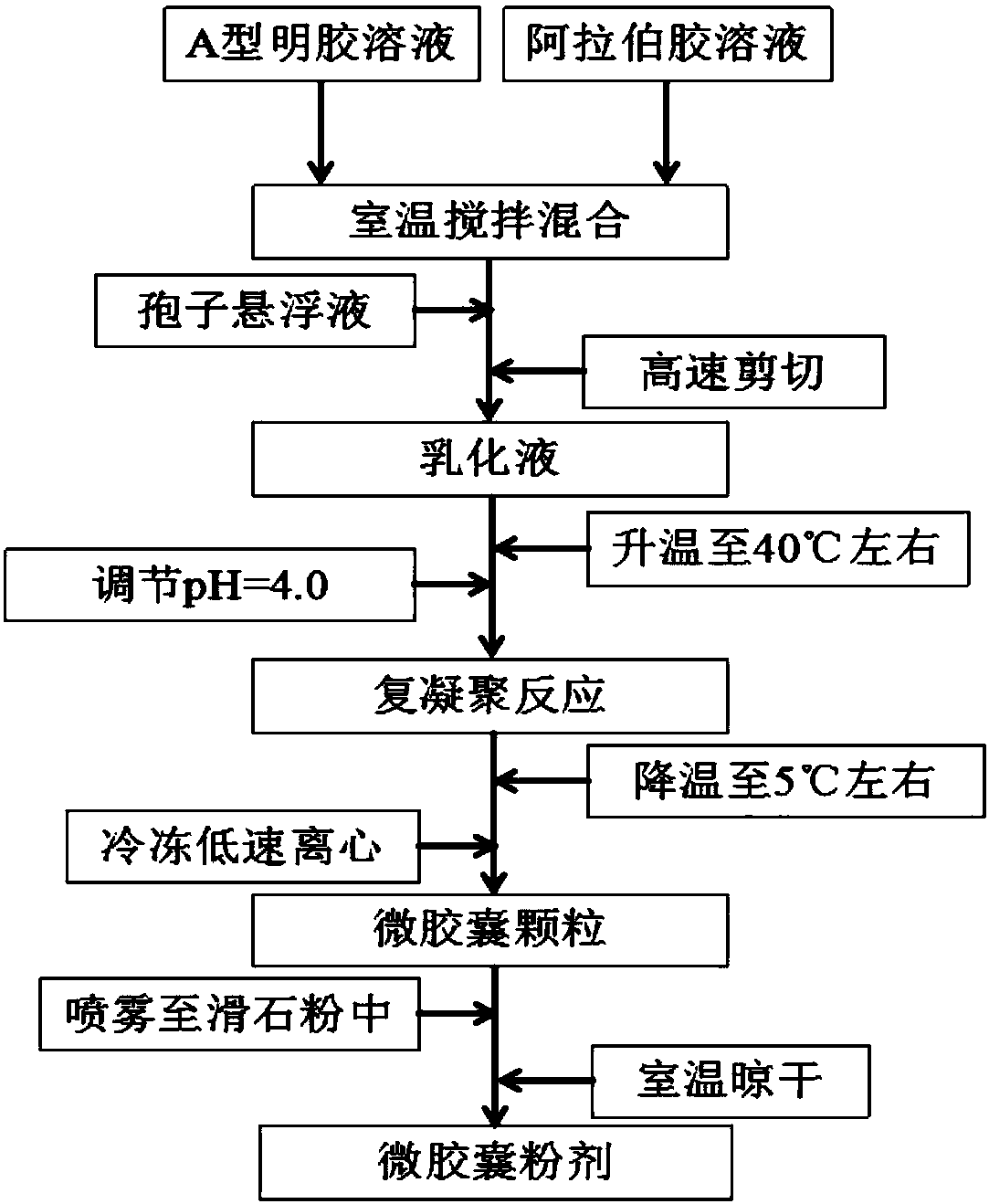

[0038] figure 1 Be the preparation method flowchart of Metarhizium anisopliae conidia microcapsules, detailed method is as follows:

[0039] S1. Capsule core preparation: Mix conidia powder of Metarhizium anisopliae and simethicone oil at a mass ratio of 1:20 (g / g), and mix thoroughly by vortex stirring at room temperature to obtain a core material solution.

[0040] S2. Emulsion preparation: mix equal volumes of gelatin A and gum arabic solutions with a concentration of 2% w / v, stir evenly, and prepare wall materials; place them at room temperature or in a water bath at 25-80°C to prevent re- Form a gel. Then add the core material solution with the same quality as the wall material, shear the mixed solution for 10 minutes at an ultra-high speed speed of 10000r / min for emulsification, and obtain an oil-in-water emulsion with uniform oil droplet size, uniform dispersion and stability.

[0...

Embodiment 2

[0042] Embodiment 2: single factor optimization microcapsule preparation process

[0043] Prepare Metarhizium anisopliae conidia microcapsule powder according to the method described in Example 1, adopt single factor optimization method for wall material ratio, wall material mass fraction, core-wall ratio, vesicle-forming pH, vesicle-forming temperature, stirring speed to microcapsule The preparation process is optimized. The results showed that under certain treatment conditions, the ratio of wall material (mass of gelatin: mass of gum arabic), the mass fraction of wall material, the ratio of core to wall and the stirring speed had a great influence on the formation of microcapsules, while the pH factor had a great influence on the formation of microcapsules. The shape has little effect ( Figure 2-5 , Figure 7 ). When the wall material ratio is 3:1 or 2:1, the microcapsules stick together and form a group, while when the wall material ratio is 1:1 and 1:2, the microcapsu...

Embodiment 3

[0044] Embodiment 3: the preparation method (A) of the metarhizium anisopliae conidia microcapsule of optimization

[0045] S1. Capsule core preparation: mix conidia powder of Metarhizium anisopliae and simethicone oil at a mass ratio of 0.5:20 (g / g), and mix thoroughly by vortex stirring at room temperature to obtain a water content of less than 5%. , spore content 1×10 11 The oil suspension of conidia of Metarhizium anisopliae more than one / mL is the core material solution.

[0046] S2. Emulsion preparation: take an appropriate amount of type A gelatin, dissolve it under the condition of heating in a water bath at 40°C to form a type A gelatin solution with a mass concentration of 2% w / v, and take another amount of gum arabic equal to that of type A gelatin, add distilled water and put in a water bath Heating to 40°C, stirring slowly at a rate of 500r / min to form a gum arabic solution with a mass concentration of 2% w / v; both the type A gelatin and the gum arabic solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com