Preparation method of modified water-based polyurethane coating

A water-based polyurethane modification technology, applied in the field of preparation of modified water-based polyurethane coatings, can solve the problems of inability to carry out large-scale production, harsh reaction conditions, complex preparation process, etc., and achieve good operability and repeatability and excellent reaction conditions Gentle, agglomeration-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

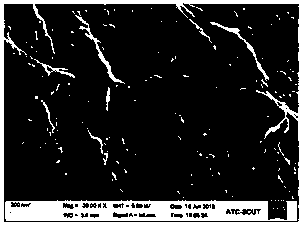

Image

Examples

Embodiment 1

[0025] (1) Preparation of modified graphene: uniformly disperse 0.8g graphene oxide in water to make a 2mg / mL graphene oxide suspension, and add 0.2g dopamine to mix evenly, and adjust to pH = 8.5, react at 0°C to obtain a modified graphene suspension.

[0026] (2) Preparation of modified nano-silicon dioxide: 1 g of nano-silicon dioxide and 0.3 g of polyallylamine were uniformly dispersed in water, and reacted at room temperature to obtain modified nano-silicon dioxide.

[0027] (3) Composite modification: the 0.2g modified graphene obtained by step (1) and the 15g modified nano-silicon dioxide obtained by step (2) are dispersed in 85g water-based polyurethane, 1500rpm high-speed stirring and mixing at room temperature for 1h, Then, the solvent was distilled off under reduced pressure to obtain a modified water-based polyurethane coating.

[0028] In the modified water-based polyurethane coating prepared in (3), the mass percentage of the modified graphene accounting for the...

Embodiment 2

[0030] (1) Preparation of modified graphene: uniformly disperse 0.8g graphene oxide in water to make a 2mg / mL graphene oxide suspension, and add 0.4g dopamine to mix evenly, and adjust to pH= 8.5, react at 0°C to obtain a modified graphene suspension.

[0031] (2) Preparation of modified nano-silicon dioxide: 1 g of nano-silicon dioxide and 0.6 g of polyallylamine were uniformly dispersed in water, and reacted at room temperature to obtain modified nano-silicon dioxide.

[0032] (3) Composite modification: the 0.4g modified graphene obtained by step (1) and the 15g modified nano-silicon dioxide obtained by step (2) are dispersed in 85g water-based polyurethane, 1500rpm high-speed stirring and mixing at room temperature for 1h, Then, the solvent was distilled off under reduced pressure to obtain a modified water-based polyurethane coating.

[0033] In the modified water-based polyurethane coating prepared in (3), the mass percent of the modified graphene in the total system is...

Embodiment 3

[0035] (1) Preparation of modified graphene: 0.8g graphene oxide is uniformly dispersed in water to make a 2mg / mL graphene oxide suspension, and 0.6g dopamine is added to mix evenly, and adjusted to pH = 8.5, react at 0°C to obtain a modified graphene suspension.

[0036] (2) Preparation of modified nano-silicon dioxide: 1 g of nano-silicon dioxide and 0.9 g of polyallylamine were uniformly dispersed in water, and reacted at room temperature to obtain modified nano-silicon dioxide.

[0037] (3) Composite modification: the 0.6g modified graphene obtained by step (1) and the 15g modified nano-silicon dioxide obtained by step (2) are dispersed in 85g water-based polyurethane, 1500rpm high-speed stirring and mixing at room temperature for 1h, Then, the solvent was distilled off under reduced pressure to obtain a modified water-based polyurethane coating.

[0038] In the modified water-based polyurethane coating prepared in (3), the mass percent of the modified graphene in the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com