Method for recovering iron and zinc from copper tailing slag

A copper tailings slag and iron recovery technology, which is applied to fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of waste of resources and low prices, and achieve the effect of improving economic and social values and improving the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

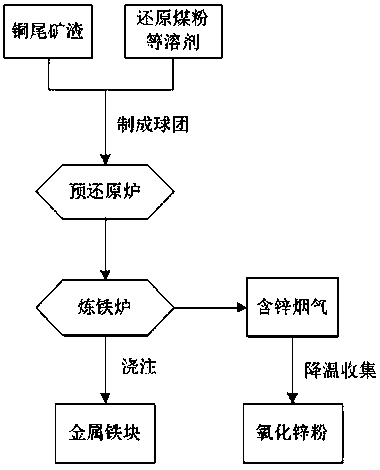

[0020] The present invention will be further explained below in conjunction with the drawings.

[0021] A method for recovering iron and zinc from copper tailings slag, and its steps are:

[0022] 1) Copper tailings containing copper, nickel, iron, zinc, silicon, calcium and other elements are mixed with reduced coal, limestone, bentonite, and NCP in the batching room through a strong mixer through a strong mixer and pelletized. After sieving and drying the green balls, enter the pre-reduction furnace, heat it to 900°C—1200°C, and reduce part of the tailings, then enter the next step ironmaking furnace;

[0023] 2) The temperature is increased to 1200-1600°C in the ironmaking furnace, and the materials continue to heat up and melt, and the materials melt to form a liquid molten pool, reducing oxides such as zinc oxide and iron oxide;

[0024] 3) The reduced zinc enters the flue gas system in the form of steam, cools down, and collects the dust to obtain dust rich in zinc oxide;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com